I stumbled across this alternative engine program and was impressed by the level of support it has been gaining. The design is based on opposing cylinders which has been attempted before. However, CFD analysis and a methodical engineering approach seems to have allowed the design to get past previous drawbacks which led others to abandon or ignore it. A joint venture with Cummins is now building a demonstrator for the US Army and commercial end users are funding continued research. If it works, they will achieve a “step change” in fuel economy while meeting future emissions standards all while being compatible with current size/weight envelopes and production tooling.

View: https://www.youtube.com/watch?v=4PCtOXjqOyE

View: https://www.youtube.com/watch?v=zf6OH4iVUkY

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Opposed Piston Engine

- Thread starter fredymac

- Start date

Interesting, basically a revival of the Junkers opposed-piston diesel principle. I'm surprised they can meet modern emissions standards with a two-stroke design. Also interesting; in the animation they show the intake/exhaust ports almost at the bottom of the stroke, so they'll be shut most of the time. They'll need a compressor for the engine to run at all.

- Joined

- 9 November 2008

- Messages

- 1,070

- Reaction score

- 158

Hobbes said:They'll need a compressor for the engine to run at all.

In this video they talk about it having a supercharger. You can see it in the animations as the rectangular object near the top of the engine mounted on the side.

- Joined

- 4 July 2010

- Messages

- 2,354

- Reaction score

- 2,572

There's a few opposed-piston concepts making the transition to the real world recently. I've been following the Ecomotors "OPOC" off an on for awhile:

View: https://www.youtube.com/watch?v=5Y8QqeuvArE

- Joined

- 26 January 2011

- Messages

- 2,223

- Reaction score

- 580

Germany and France developed opposed engine designs way back in the 1930s. What is spectacularly difference about this compared to their designs? The French used one in their EBR 8 wheeled armoured car post-WWII.

E

Eirigi

Guest

.

- Joined

- 29 September 2006

- Messages

- 1,679

- Reaction score

- 1,147

Eirigi said:Immature for whom? By the time the Leyland L60 (and the Napier Deltic, to a lesser extent) proved unreliable in England, opposed-piston diesel engines had already accumulated hundreds of thousands if not millions of operating hours in ships, tugs, submarines, locomotives and aircraft, worldwide. The technology was perfectly mastered by companies such as Fairbanks&Morse (their engines were so reliable that they are still used to this day by the USN for auxiliary/emergency power in nuclear-powered submarines, and not counting their Soviet derivatives found in thousands of locomotives), Junkers Flugmotoren, ...

Perhaps with the L60 being used as a tank engine it encountered greater power variation in common use than many of other vehicles you mentioned?

- Joined

- 9 October 2009

- Messages

- 20,815

- Reaction score

- 11,790

I think goose was referring to opposed-piston multi-fuel engines.

goose

ACCESS: Restricted

- Joined

- 14 July 2010

- Messages

- 29

- Reaction score

- 6

My point is not that opposed piston engines are inherently flawed but that any unconventional engine has an uphill struggle to gain acceptance. The memory of the L60 will be the elephant in the room when discussing this engine. I know it was underdeveloped & that is a warning to this team-it has to be right first time!

Reply to post #4

The EBR used a conventional flat-12, air-cooled, four-stroke, gasoline engine of 6 liter capacity. It developed about 200hp. It was remarkable for its flatness: only about 8 inches high. This meant that the engine fitted onder the turret floor. It did however mean that the turret had to be romved for major work on the engine.

The EBR used a conventional flat-12, air-cooled, four-stroke, gasoline engine of 6 liter capacity. It developed about 200hp. It was remarkable for its flatness: only about 8 inches high. This meant that the engine fitted onder the turret floor. It did however mean that the turret had to be romved for major work on the engine.

Reply to post #6

Yes the Chieftain was a remarkable tank for its time but the whole thing was spoiled by the dismal engine. It would have been a world beater with the US Continental engine (of the M60) ot the MTU engine of the Leopard I, the other two major Western tanks from the same era.

Yes the Chieftain was a remarkable tank for its time but the whole thing was spoiled by the dismal engine. It would have been a world beater with the US Continental engine (of the M60) ot the MTU engine of the Leopard I, the other two major Western tanks from the same era.

E

Eirigi

Guest

.

- Joined

- 1 May 2007

- Messages

- 2,515

- Reaction score

- 1,698

Herman said:Reply to post #6

Yes the Chieftain was a remarkable tank for its time but the whole thing was spoiled by the dismal engine. It would have been a world beater with the US Continental engine (of the M60) ot the MTU engine of the Leopard I, the other two major Western tanks from the same era.

Ahem...

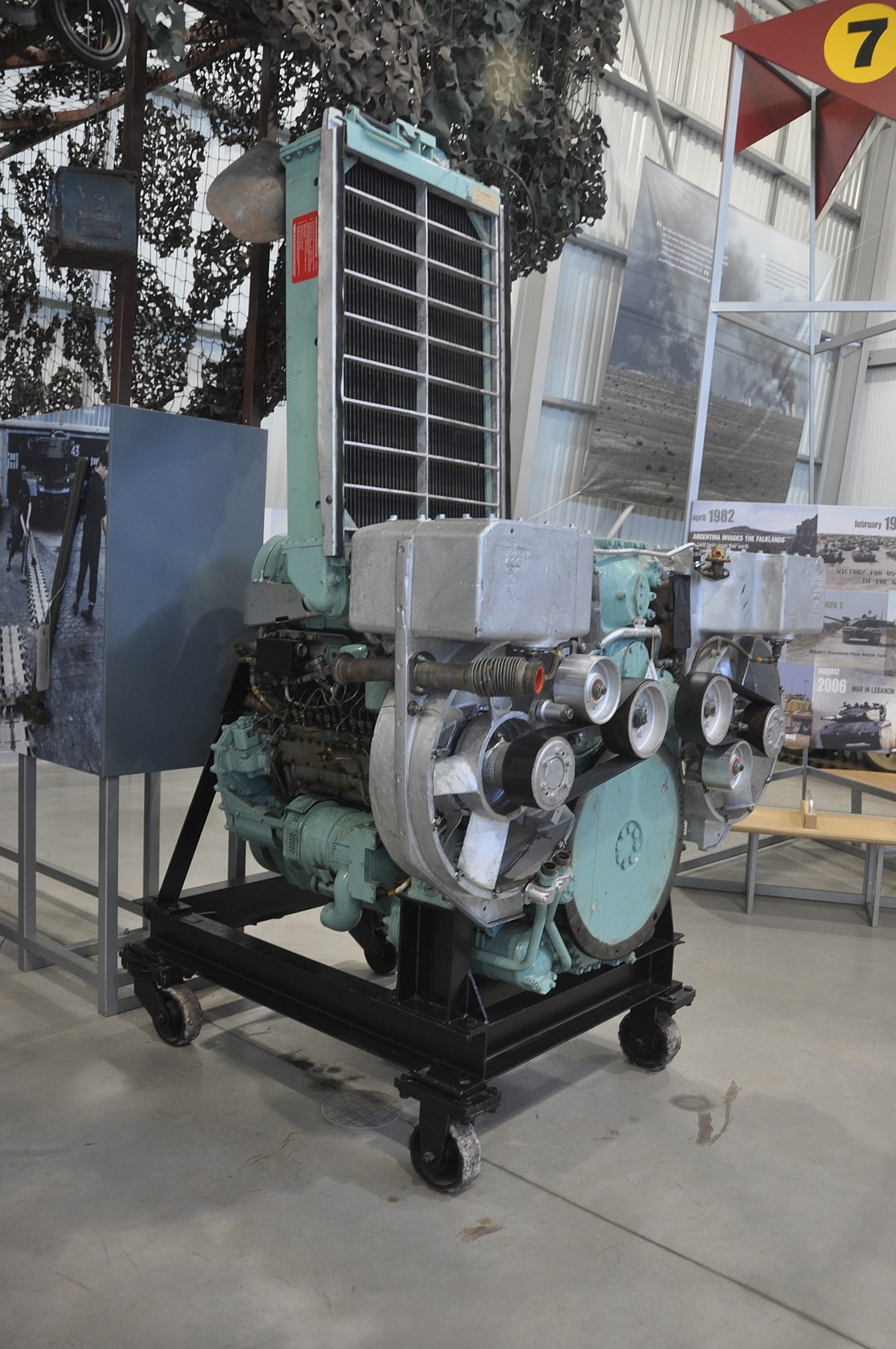

The photo caption reads :-

"A rear shot of a very unusual Chieftain indeed; notice the absence of the usual exhaust box and pipes. This is because, automotively speaking, it

is the most powerful Chieftain ever built. Instead of the problematic L60 and TN12 power pack it was fitted with an MTU diesel linked to a Renk auto gear box. This combination made it powerful and very fast; it also had the ability to stop on the proverbial “sixpence” as one employee found out.

Although it is located at a museum, its interior is in poor condition and needs a lot of work.

The power pack is still classed as a commercial secret. (R. Griffin)"

Source, 'The Armour Journal', Summer 2015.

cheers,

Robin,

Attachments

Reply to post # 14.

Robin, this is a really, really interesting piece of information. It would be very interesting to know when this prototype was built and by whom. It would also be interesting to know which MTU engine is fitted in the vehicle. The Leopard I, which corresponded with the Chieftain chronologically, was fitted with a 10 cylinder, 830hp unit but it used a ZF gearbox. The Leopard 2 had a V12, 1500hp MTU engine and that was indeed coupled to a Renk gearbox. The Leopard 2 is however a later tank than the Chieftain, corresponding more to the Challenger. Why would anybody stick a Leopard 2 powerpack into a Chieftain? It will also not be simple, technically; the Leopard powerpack is considerably larger than that of the Chieftain.

Robin, this is a really, really interesting piece of information. It would be very interesting to know when this prototype was built and by whom. It would also be interesting to know which MTU engine is fitted in the vehicle. The Leopard I, which corresponded with the Chieftain chronologically, was fitted with a 10 cylinder, 830hp unit but it used a ZF gearbox. The Leopard 2 had a V12, 1500hp MTU engine and that was indeed coupled to a Renk gearbox. The Leopard 2 is however a later tank than the Chieftain, corresponding more to the Challenger. Why would anybody stick a Leopard 2 powerpack into a Chieftain? It will also not be simple, technically; the Leopard powerpack is considerably larger than that of the Chieftain.

Reply to post # 7.

I agree. The technology was mature and opposed piston two-stroke engines have been widely used, also in military vehicles. The Russians/Ukranians made/make wide use of this type of engine in various modified vesrions of the T72 tank. The Chieftain was simply a poor execution of the principle.

The attraction of this type of engine, before the era of high pressure, common rail injection, variable geometry turbocharging and electronic engine management systems, was that it offered reatively high power from a relatively small engine. Britian wanted this type of engine for the Chieftain for this reason and because it was felt that this type of engine was more suitable for multi-fuel use than conventional diesels. Multi-fuel capability was a requirement for new tanks at the time of the development of the Leopard 1, the AMX-30 and the Chieftain. Rolls Royce apparently had the design of a conventional, 4-stroke, V8, diesel intended for the Chieftain ready for production when it was deceided to rather edevlop the L60. The irony is that it apparently took fitters 24 hours to modify the engine for use with petrol.

I agree. The technology was mature and opposed piston two-stroke engines have been widely used, also in military vehicles. The Russians/Ukranians made/make wide use of this type of engine in various modified vesrions of the T72 tank. The Chieftain was simply a poor execution of the principle.

The attraction of this type of engine, before the era of high pressure, common rail injection, variable geometry turbocharging and electronic engine management systems, was that it offered reatively high power from a relatively small engine. Britian wanted this type of engine for the Chieftain for this reason and because it was felt that this type of engine was more suitable for multi-fuel use than conventional diesels. Multi-fuel capability was a requirement for new tanks at the time of the development of the Leopard 1, the AMX-30 and the Chieftain. Rolls Royce apparently had the design of a conventional, 4-stroke, V8, diesel intended for the Chieftain ready for production when it was deceided to rather edevlop the L60. The irony is that it apparently took fitters 24 hours to modify the engine for use with petrol.

Herman said:Reply to post # 7.

I agree. The technology was mature and opposed piston two-stroke engines have been widely used, also in military vehicles. The Russians/Ukranians made/make wide use of this type of engine in various modified vesrions of the T72 tank. The Chieftain was simply a poor execution of the principle.

Herman, you can use the 'quote' function to include the relevant text of the post you're replying to. That makes your posts more readable than they are now (where we have to manually look up which post was #7).

- Joined

- 1 May 2007

- Messages

- 2,515

- Reaction score

- 1,698

Herman said:Reply to post # 14.

Robin, this is a really, really interesting piece of information. It would be very interesting to know when this prototype was built and by whom. It would also be interesting to know which MTU engine is fitted in the vehicle. The Leopard I, which corresponded with the Chieftain chronologically, was fitted with a 10 cylinder, 830hp unit but it used a ZF gearbox. The Leopard 2 had a V12, 1500hp MTU engine and that was indeed coupled to a Renk gearbox. The Leopard 2 is however a later tank than the Chieftain, corresponding more to the Challenger. Why would anybody stick a Leopard 2 powerpack into a Chieftain? It will also not be simple, technically; the Leopard powerpack is considerably larger than that of the Chieftain.

Here we go...

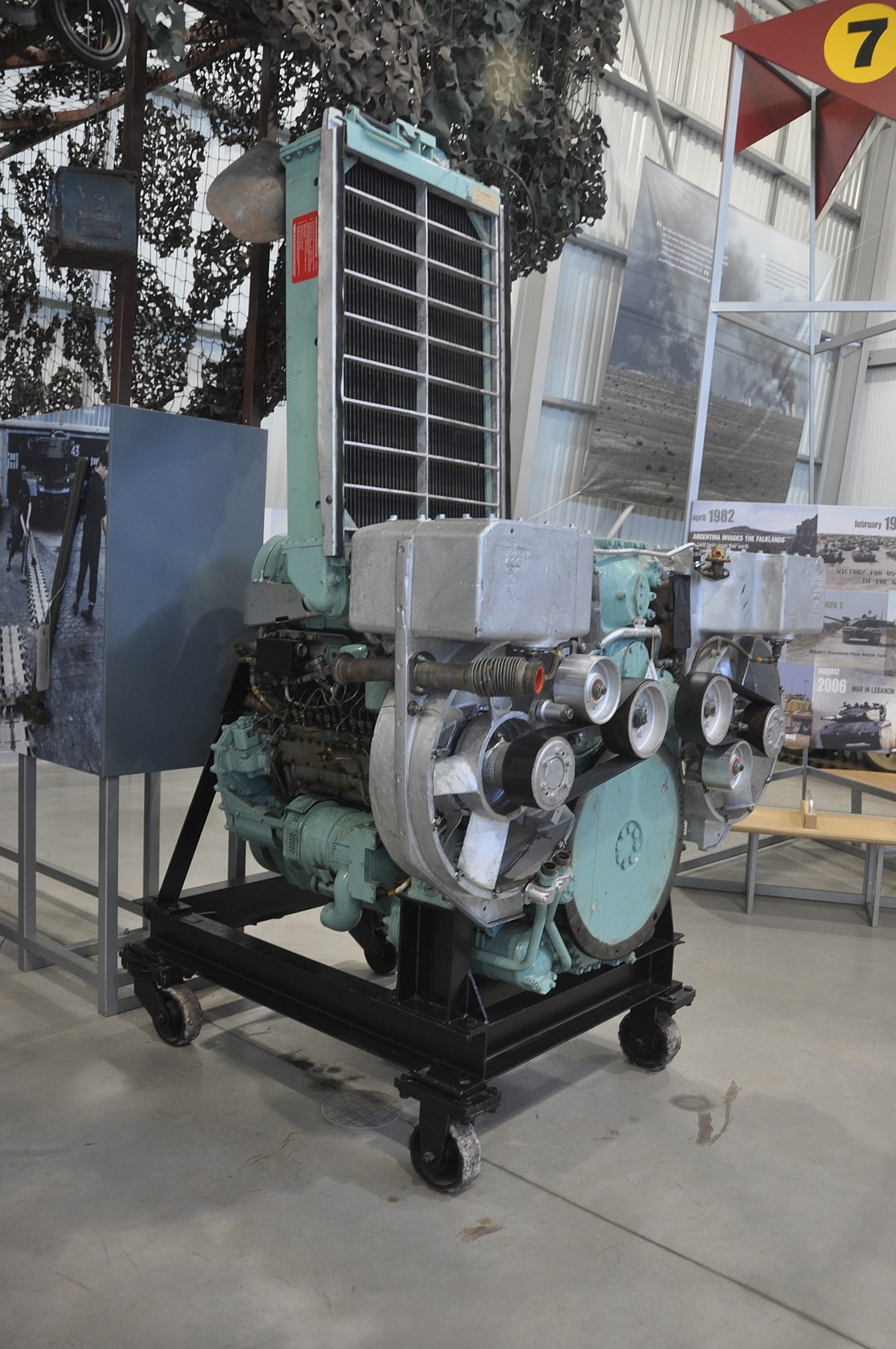

"The development of the Chieftain with a 1000hp engine and enhanced transmission was a project by Vickers Defence Industries, in partnership with the German companies RENK, MTU and Krupp-MAK, to offer a significant performance and reliability upgrade for existing Chieftain tanks. The first customer was to be Kuwait immediately before the first Gulf War. The MoD expressed an interest in upgrading their engineer vehicles and the BARV (Beach Armoured Recovery Vehicle) of the Royal Marines. Subsequently most of Kuwait’s Chieftain fleet was scrapped. The improved design was not developed further, however, leaving this unique prototype as the most powerful Chieftain Tank ever built.

The prototype was donated by Vickers Defence Industries to the Museum and delivered on 15th January 2002. The German engine and transmissions include features which are still regarded as industrial secrets and there are strict conditions relating to access attached to the donation. The tank, which still functions, has been partially restored with support from RENK, Vickers and 150 Regiment, Royal Logistics Corp."

Source :-

Vickers Chieftain Battle Tank - Yorkshire Air Museum

The original Chieftain Main Battle Tank weighed 55 tons combat-loaded and was armed with a 120 mm main gun, a 7.62 mm coaxial machine gun and a 7.62 mm anti-aircraft gun. Powered by a Leyland 750 hp 6 cylinder diesel engine, it had a road speed of about 30 mph and a range of action …

yorkshireairmuseum.org

yorkshireairmuseum.org

Also, another image from the magazine article quoted in post #14; caption reads

"The strange contraption on the pack (sic) of the MTU Chieftain is actually a lifting frame to help lift one piece engine deck which is not on a torsion bar unlike a similar system in Challenger. The frame is stowed when not in use so as not to hinder traverse."

cheers,

Robin.

Attachments

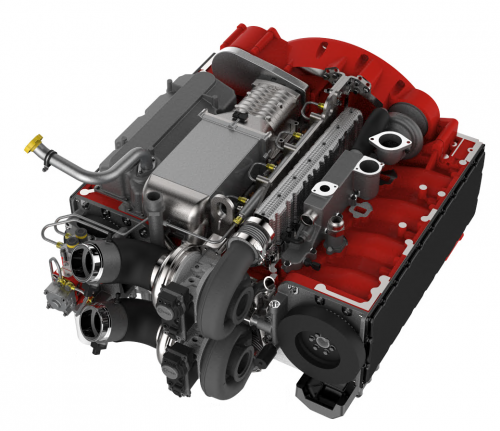

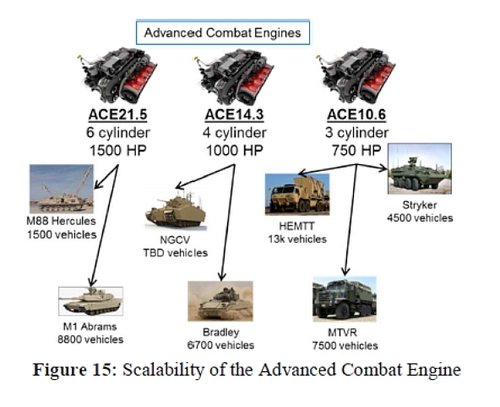

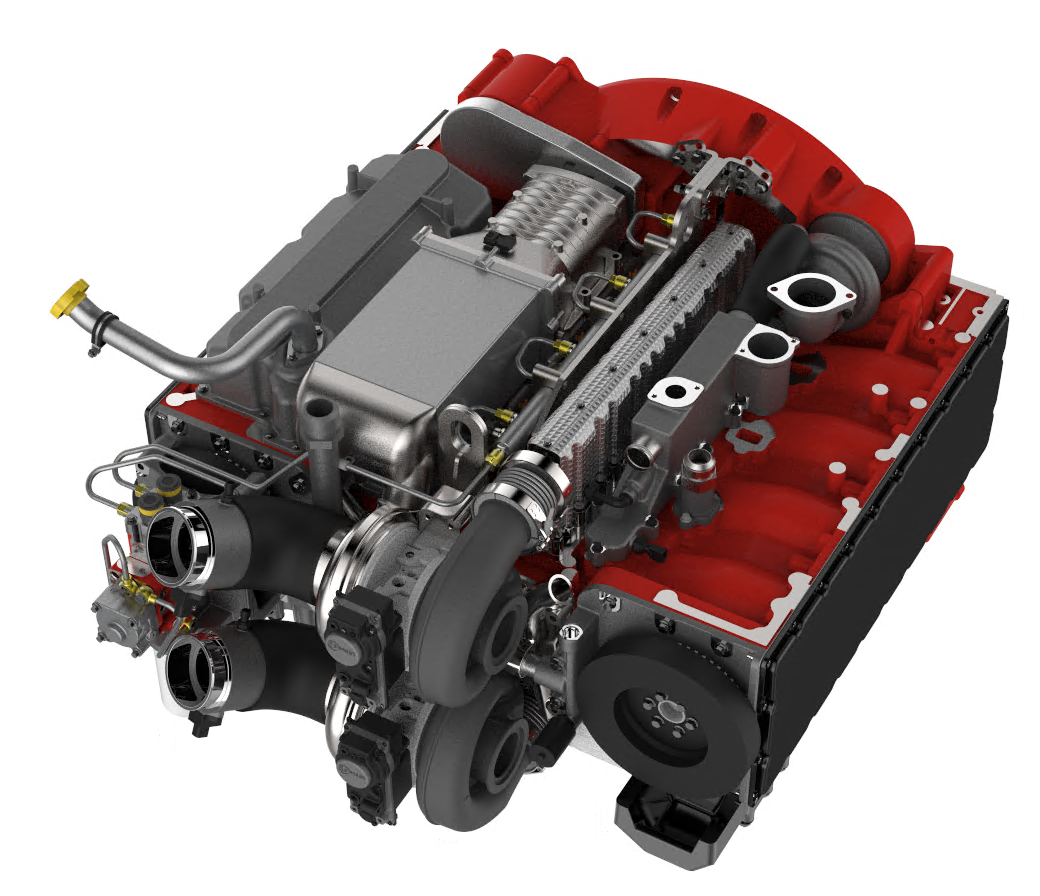

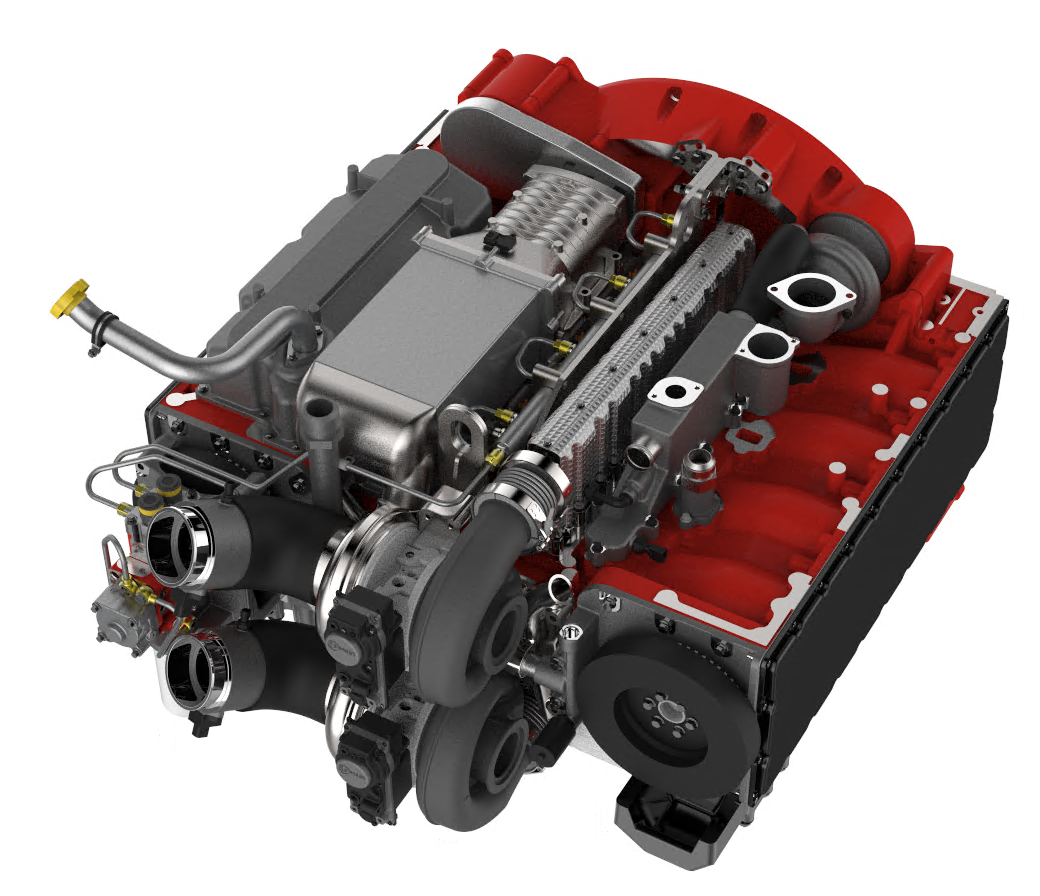

Looks like the Army was delayed a year or more in releasing the "Advanced Combat Engine" contract to get the ball rolling at Cummins. They finally funded a $47 Million contract to get started. Demonstration tests are slated for 2019 with the prototype engine specified at 1000hp and 2400 foot-pounds of torque in a 4 cylinder, 14.3 liter package.

View: https://www.youtube.com/watch?v=adoST4TbJz4

4:35 mark on video below discusses a commercial pickup engine

View: https://www.youtube.com/watch?v=Dh6YZl6Ueec

4:35 mark on video below discusses a commercial pickup engine

- Joined

- 19 July 2016

- Messages

- 3,922

- Reaction score

- 2,943

Something that needs to be considered when judging chieftain is the financial situation of the time, which influenced the development of the vehicle and selection of its engine. That being political it cannot be discussed, nor the choice of supplier of the motive power of the vehicle which influenced the development required and need of the recipient for funding to remain afloat, especially when the company involved was a politically created one. So, looking at non political influences and reasons for the vehicle having slewed opinions of its abilities.

1. Like many vehicles it became heavier during design and development which affects the efficacy of the powertrain. Nothing new, take a look at the Panther.

2. The frontal armour was in its day pretty impressive but side armour was thinner than late versions of the Panther at 38mm with 13mm of side skirt. Not great.

3. The gun itself was pretty good for its day with acceptable accuracy and rate of fire. The shells fired were also reasonable for the day and the APFSDS was apparently available for Chieftain but I myself never got to load or fire it.

4. Restrictions. When I joined my regiment we were growing the tank force and went from four squadrons to five and three tank troops to four. We exercised regularly with many 24 hour sessions in the vehicle with extended periods operating under NBC conditions. After 1979 cutbacks became the norm and we were restricted initially by track miles, engine hours and then engine revolutions. At the same time we were constantly checking fluid levels. The biggest bain in the life of the L-60 was not the engine itself but the coolant system. The fan belts were ripping the fans from the housing and leaving a 29 gallon yellow cloud which, if the Russians and East Germans had appreciated the fact, been a great giveaway to our locations rather than follow our moves by mark one eyeball. The methods used to address this problem were, reducing the hours on the engine and the, drilling holes in the fan belts to prevent the belt from ripping the fan from its housing. The result of this was that the fan belt failed and while being ripped apart, destroyed coolant lines hence, 29 gallon yellow clouds showing where we were when the failure happened. So over maintained and with pathetic so called fix programs we had an engine with high failure rates that did not have to be. Sorry, politics?

5. Apparently the last chieftains had the Perkins diesel engine so if it was possible then upgrades should have been possible. The question should be WHY WOULD YOU WANT TO? The hull was over reliant on it frontal arc protection when the tactical use required situation from pre prepared firing points with little manouvre being required and that being from firing point/line to the next fallback firing point/line. While we exercised forward movement this was not something we expecting to do in an actual conflict scenario other than localised counter attacks to straighten a defensive line. Considering the trilogy of armour, we were giving one away right from the start. Brigadier General Sir John Hacket wrote a book about this scenario (World war three) but considered that while the warsaw pact forces WOULD get to the French border, they would have real problems with choke points and be delayed from their schedule enough that localised nuclear engagement was a realistic scenario.

6. There was a bit of folk lore/myth about the Germans offering an MB diesel engine for free, this was during development of the Leopard 2 I believe but then folk lore/myth rarely have an interest in the truth so I offer it here for what it is, uncorroborated fish wives tales. Apparently while developing a power pack for Leopard (?) several engines were tested, this does indeed sound like German methodology. One engine was found to be acceptable in all areas but power, it was developing 1400bhp rather than 1500bhp, so this engine was apparently offered to the UK as a fully developed engine/transmission unit. Obviously it was not accepted, something else quite credible.

1. Like many vehicles it became heavier during design and development which affects the efficacy of the powertrain. Nothing new, take a look at the Panther.

2. The frontal armour was in its day pretty impressive but side armour was thinner than late versions of the Panther at 38mm with 13mm of side skirt. Not great.

3. The gun itself was pretty good for its day with acceptable accuracy and rate of fire. The shells fired were also reasonable for the day and the APFSDS was apparently available for Chieftain but I myself never got to load or fire it.

4. Restrictions. When I joined my regiment we were growing the tank force and went from four squadrons to five and three tank troops to four. We exercised regularly with many 24 hour sessions in the vehicle with extended periods operating under NBC conditions. After 1979 cutbacks became the norm and we were restricted initially by track miles, engine hours and then engine revolutions. At the same time we were constantly checking fluid levels. The biggest bain in the life of the L-60 was not the engine itself but the coolant system. The fan belts were ripping the fans from the housing and leaving a 29 gallon yellow cloud which, if the Russians and East Germans had appreciated the fact, been a great giveaway to our locations rather than follow our moves by mark one eyeball. The methods used to address this problem were, reducing the hours on the engine and the, drilling holes in the fan belts to prevent the belt from ripping the fan from its housing. The result of this was that the fan belt failed and while being ripped apart, destroyed coolant lines hence, 29 gallon yellow clouds showing where we were when the failure happened. So over maintained and with pathetic so called fix programs we had an engine with high failure rates that did not have to be. Sorry, politics?

5. Apparently the last chieftains had the Perkins diesel engine so if it was possible then upgrades should have been possible. The question should be WHY WOULD YOU WANT TO? The hull was over reliant on it frontal arc protection when the tactical use required situation from pre prepared firing points with little manouvre being required and that being from firing point/line to the next fallback firing point/line. While we exercised forward movement this was not something we expecting to do in an actual conflict scenario other than localised counter attacks to straighten a defensive line. Considering the trilogy of armour, we were giving one away right from the start. Brigadier General Sir John Hacket wrote a book about this scenario (World war three) but considered that while the warsaw pact forces WOULD get to the French border, they would have real problems with choke points and be delayed from their schedule enough that localised nuclear engagement was a realistic scenario.

6. There was a bit of folk lore/myth about the Germans offering an MB diesel engine for free, this was during development of the Leopard 2 I believe but then folk lore/myth rarely have an interest in the truth so I offer it here for what it is, uncorroborated fish wives tales. Apparently while developing a power pack for Leopard (?) several engines were tested, this does indeed sound like German methodology. One engine was found to be acceptable in all areas but power, it was developing 1400bhp rather than 1500bhp, so this engine was apparently offered to the UK as a fully developed engine/transmission unit. Obviously it was not accepted, something else quite credible.

- Joined

- 19 July 2016

- Messages

- 3,922

- Reaction score

- 2,943

The Jordanian Khalid is essentially a Chieftain and had 1200bhp so is reasonably the most powerful Chieftain.

First application to make production is a revised Fairbanks Morse power generation engine. Design/engineering was provided by Achates to replace an early generation opposed piston design that Fairbanks Morse had been producing since it was founded.

View: https://www.youtube.com/watch?v=R2xJgXbbuN0

Interview with an Achates exec updating where the company is in bringing other projects to production.

View: https://www.youtube.com/watch?v=8qmAlnIh4mk

Interview with an Achates exec updating where the company is in bringing other projects to production.

- Joined

- 16 April 2008

- Messages

- 8,916

- Reaction score

- 12,326

Same image, minus the text.

www.insideindianabusiness.com

www.insideindianabusiness.com

Cummins to Design Combat Engines That Elude the Enemy - Inside INdiana Business

The monstrous, larger-than-life military tanks of tomorrow could be powered by Hoosier ingenuity. A recent $47 million defense contract delivers marching orders for Columbus-based Cummins Inc.: dev...

Cummins to Design Combat Engines That Elude the Enemy

Posted: Feb 15, 2018 9:26 AM EST

Updated: Feb 15, 2018 9:26 AM EST

By Kylie Veleta, Special Projects ReporterCONNECT

The Advanced Combat Engine aims to deliver more power in a smaller package.

The monstrous, larger-than-life military tanks of tomorrow could be powered by Hoosier ingenuity. A recent $47 million defense contract delivers marching orders for Columbus-based Cummins Inc.: develop the next-generation engine to power U.S. combat vehicles, and it must be stronger, but smaller, and elusive to enemies’ efforts to spot it. The project is a milestone for Cummins, marking one of the largest research contracts the manufacturer has inked with the military.

The National Advanced Mobility Consortium, which awarded the contract, has tasked Cummins with three key requirements for the Advanced Combat Engine (ACE) project. Cummins Vice President of Research and Technology Wayne Eckerle says the most challenging is to reduce heat rejection by 21 percent, compared to current combat vehicles, which are also powered by Cummins engines.

“If the engine is rejecting a lot of heat, you have a thermal signature that makes it easier for the enemy to find the tank; that heat has to be dissipated somewhere on the vehicle, because the heat signature can be seen with infrared or some other technology,” says Eckerle. “It means the tank has to have a very significant cooling system to keep the engine cool.”

The manufacturer is working with California-based Achates Power, a longtime partner that has developed an engine that Cummins’ expertise will help take to the next level and open the door to production. In addition to low heat rejection, the two companies will combine forces to meet demanding power requirements for the engine: the project aims to improve power density by more than 50 percent, compared to current combat engines.

“[The military] is after an engine that could deliver more power in a smaller package size,” says Eckerle. “Even though those tanks look very, very large, the actual space for the engine is confined. The [military] wants an engine that can put out the power needed and still be in a relatively small package size.”

Similar to reducing heat rejection, increasing power density works toward the ultimate goal of making U.S. troops safer.

“One of the reasons the engine compartment is so small is, there’s a lot of protective covering put on these vehicles,” says Eckerle. “If you can compartmentalize the engine to a smaller space, that leaves more space for putting protection on the vehicle to protect the people inside it. And because of the extra power, you can put more armor on the vehicle and still deliver the mission.”

A third requirement for the diesel engine is to reduce fuel use by 13 percent. Cummins says research and development is well underway at its Columbus headquarters and prototype parts will arrive in the coming months. The manufacturer expects to build a handful of prototype engines at its Seymour facility. Ultimately, Cummins plans to demonstrate the engine in the full power train to show it will deliver on the specifications.

“Cummins was chosen for this contract because the government wanted a company that could, potentially, take the concept into production. [Our focus] is taking Achates’ ideas and turning them into a production-viable engine; they’ve demonstrated the technology in a sample configuration,” says Eckerle. “[Cummins] is in the process of laying out how’d we take it into production, if and when that happens, and the costs that go with it.”

While the research contract is among the company’s largest in the defense sector, Eckerle believes the ACE project could open doors for advancing engines in Cummins’ commercial applications, such as marine and industrial segments—delivering Cummins’ might to more than just the military.

Attachments

- Joined

- 19 July 2016

- Messages

- 3,922

- Reaction score

- 2,943

Nothing new under the sun, they did that with the Panhard EBR. It seems that the industry comes up with these buzz word puzzles whenever they want to justify spending and research. Not a problem in and of itself but how many of these programs go anywhere and at what cost do they go nowhere?

- Joined

- 19 July 2016

- Messages

- 3,922

- Reaction score

- 2,943

It is a horizontally opposed boxer type engine.

To clarify:

horizontally opposed boxer type engine: crankshaft in the middle, 2 cylinders, 2 pistons pointing outward. Normal cylinders with a cylinder head at the top.

opposed-piston engine: 2 crankshafts on the ends, 2 pistons share ONE cylinder. No cylinder head, so has to use ports in tthe cylinder wall. Very different.

horizontally opposed boxer type engine: crankshaft in the middle, 2 cylinders, 2 pistons pointing outward. Normal cylinders with a cylinder head at the top.

opposed-piston engine: 2 crankshafts on the ends, 2 pistons share ONE cylinder. No cylinder head, so has to use ports in tthe cylinder wall. Very different.

Last edited:

- Joined

- 19 July 2016

- Messages

- 3,922

- Reaction score

- 2,943

Wrong. Sigh. I like that word it's sooo sixties. Different types of opposed cylinder engine.

- Joined

- 19 July 2016

- Messages

- 3,922

- Reaction score

- 2,943

Leyland L60 - Wikipedia

Leyland L60 - Wikipedia

en.wikipedia.org

Yes, this new reference is an opposed piston engine and illustrates the reason it dropped out of use. The whole point of Achates Power is to fix the problems in reliability, gas mileage, and air pollution which have prevented its wide spread application.

- Joined

- 19 July 2016

- Messages

- 3,922

- Reaction score

- 2,943

I must appologise, I got the wrong reference and responded badly when the first reply to my post appeared. The "SIGH" comes across as condescension which I do not react well to. I knew which engine I should have posted but having an extended bout of sinusitis and a few other niggles left me poorly equipped to shrug off the "SIGH". There are people about who served on Chieftain years after I left who suggest that after 20 years of fiddling the L-60 engine produced a reliable 850 horses, and no tired old nags which I experienced either. With hindsight, I should not have posted.

Bottleship

ACCESS: Secret

- Joined

- 30 June 2019

- Messages

- 483

- Reaction score

- 1,221

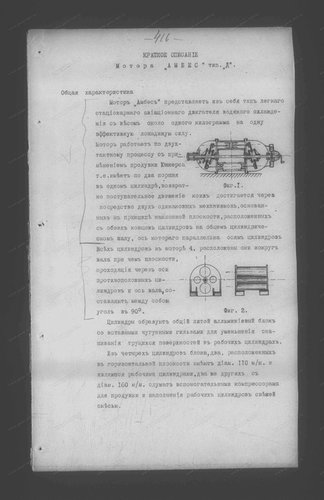

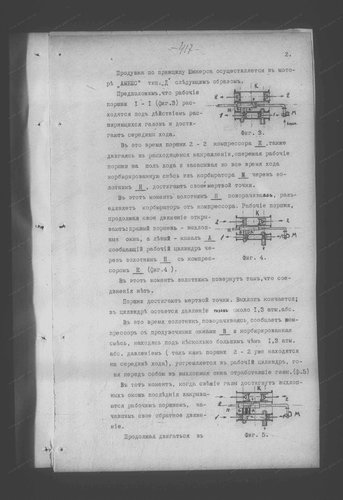

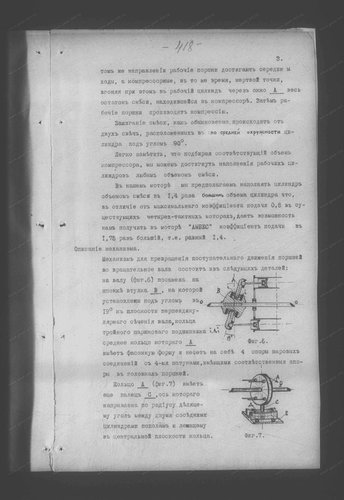

Schemes of Mikulin and Stechkin opposed piston engine (1916-1919):

Engines for aircrafts and for tanks. In latest variant of "Tsar Tank" (with axisless wheels, weight 40 ton and 57 mm gun in turret, 1917, project) was a two Mikulin and Stechkin engines.

Data of engines:

- Type A - 250 HP, 2300 rpm, 320 kg (1.28 kg/HP), 11.52 L (21.7 HP/L), four-cilinder

- Type B - 200 HP, 2000 rpm, 192 kg (0.98 kg/HP), 3.8 L (52.63 HP/L), double-cilinder

- Other variant of A or B, 300 HP at 3000 rpm - I heard about this engine for "Tsar Tank"

- Unknown 500 HP engine

In T-64 used 13.57 L opposed piston engine, with turbocharger, named a 5TDF, 700 HP at 2800 rpm (51.6 HP/L). Also, worked at 1000 HP version (73.7 HP/L).

Engines for aircrafts and for tanks. In latest variant of "Tsar Tank" (with axisless wheels, weight 40 ton and 57 mm gun in turret, 1917, project) was a two Mikulin and Stechkin engines.

Data of engines:

- Type A - 250 HP, 2300 rpm, 320 kg (1.28 kg/HP), 11.52 L (21.7 HP/L), four-cilinder

- Type B - 200 HP, 2000 rpm, 192 kg (0.98 kg/HP), 3.8 L (52.63 HP/L), double-cilinder

- Other variant of A or B, 300 HP at 3000 rpm - I heard about this engine for "Tsar Tank"

- Unknown 500 HP engine

In T-64 used 13.57 L opposed piston engine, with turbocharger, named a 5TDF, 700 HP at 2800 rpm (51.6 HP/L). Also, worked at 1000 HP version (73.7 HP/L).

Last edited:

1635yankee

Recovering aeronautical engineer

- Joined

- 18 August 2020

- Messages

- 462

- Reaction score

- 565

Fairbanks-Morse has been producing large opposed-piston engines since the 1930s and Duxford produced large, low-speed opposed-piston engines until its closure in the 1960s.

Similar threads

-

-

-

Rocketdyne Tripropellant (Hydrogene and Fluorine and Lithium) rocket engine

- Started by Michel Van

- Replies: 11

-

-

Revolutionary Engine Sends Shockwaves through the Auto Industry

- Started by bobbymike

- Replies: 22