[...]

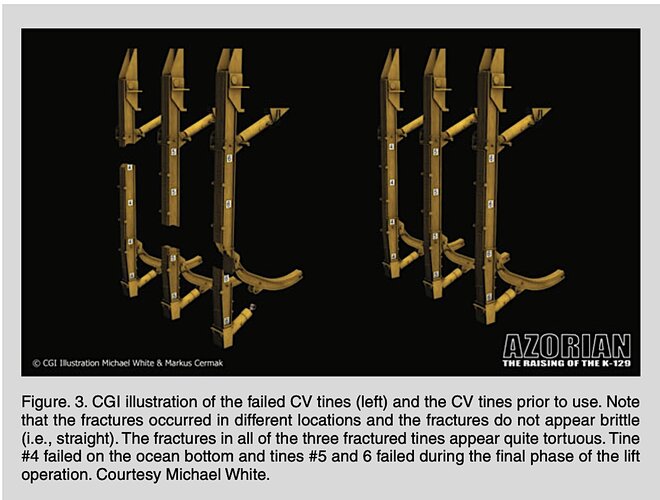

Another possible factor has been identified was the use of managing steel, which was found to become more brittle at the lower temperatures (29F in seawater at that depth). The plan was to switch to another steel in the subsequent Matador operation to retrieve the lost portion. [...]

Since reading 'Project Azorian. The CIA and the raising of the K-129' for the first time shortly after it was published, I always wanted to ask - were the 'grabbers' (as they are labeled in 'Project Azorian', on the color insert depicting 'Capture Vehicle') made out of titanium or maraging steel?

'Kelly. More Than My Share of It All', (1989 edition, p. 198) reads: "Lockheed's participation in Glomar was to design the mechanism that would pick up an abandoned Russian submarine sunk to depths of 15,000 feet. Skimping on static testing of the remotely-controlled titanium arms-failure to conduct one last test before the retrieval attempt-resulted in less that 100 percent success."

'Project Azorian', (p.135) reads: "Related to this situation was Lockheed's choice of maraging steel for the capture vehicle's beams and davits. Other steels would have allowed more deflection or 'bending,' permitting a better distribution of the load among the beams. Lockheed had selected maraging steel for those components because it has superior strength and toughness compared to ordinary structural steels. However, maraging steel is also relatively brittle, especially at low temperatures [...] Recently, information on Lockheed's selection of maraging steel has come to light. It has been revealed that the CIA provided a last-minute lift estimate that had increased the target object's weight by 500 tons. Since the capture vehicle's beams and davits were sized and the drawings released, Lockheed had no choice but to select another steel with a higher yield strength and equal ease of machining and workability in order to meet schedules."

Obviously, two versions of the same story. Intuitively, Lockheed using their titanium fabrication know-how for another CIA project in the late '60 seems plausible.