- Joined

- 4 May 2008

- Messages

- 2,439

- Reaction score

- 762

Hi all,

I often come to the forum to look at ways specific problems were solved in the past. This one is a bit tricky and i haven't found anything relevant, so i was wondering if i could solicit help directly.

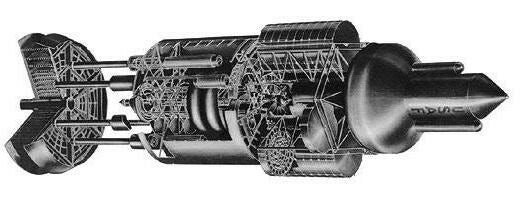

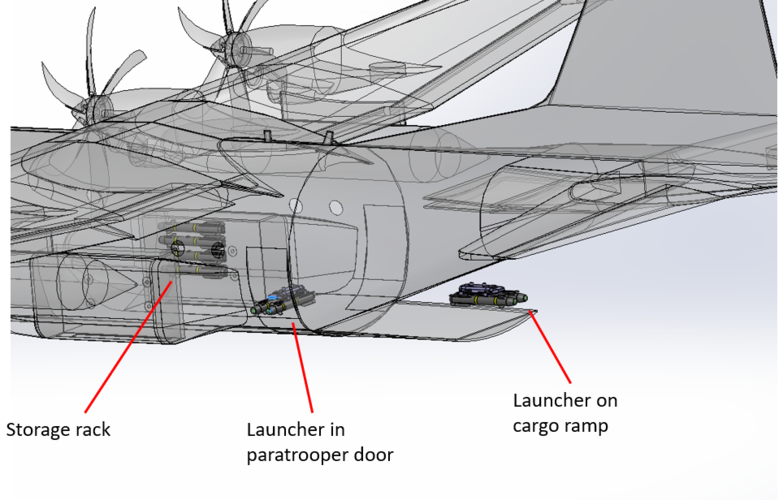

The project i'm working on requires moving heavy objects through the cabin of an air vehicle. I can't tell you the exact concept, but i can use an example that's close enough. Imagine a C-130 gunship and for some silly reason you have a retractable Hellfire launcher that you can reload from the inside. How do you safely get the missiles from storage to the launcher? It would take more than one person to lift it, and at any rate you wouldn't want to do that in turbulence.

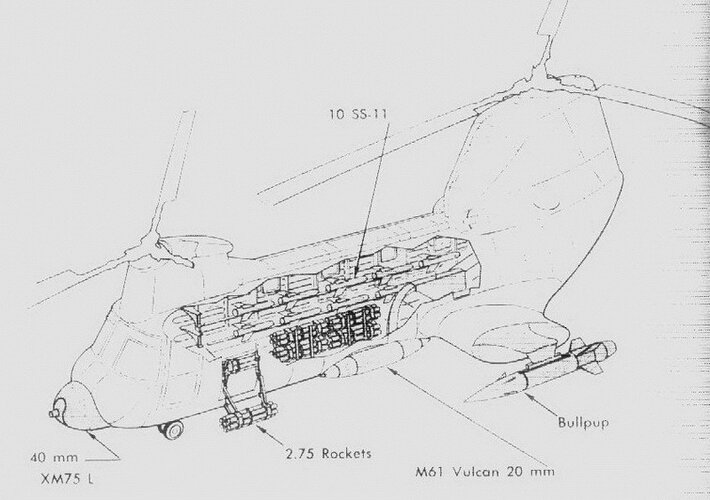

The closest comparable situation i've found is that of the Gunship CH-46 (pic below), but there's no detail of how the anti-tank missiles are moved about; they could also be lightweight enough that they were carried by hand. I'm not so sure about the rockets though.

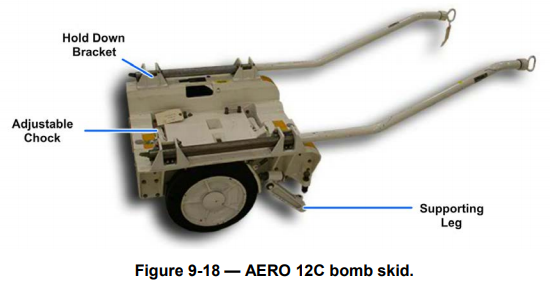

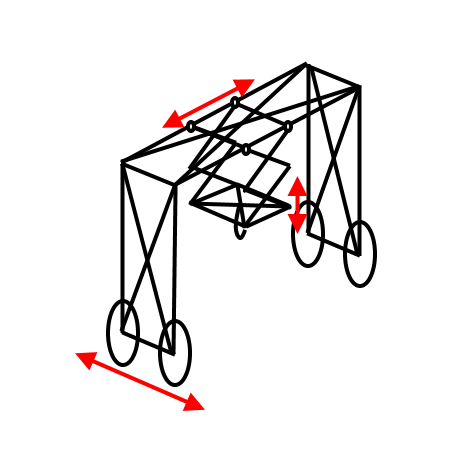

I thought you could use a small overhead gantry crane maybe. We're not talking about a lot of weight in the big scheme of things. Strap the item, lift it, and push it down the fuselage to where it needs to go. one person could do that. Or maybe it's more like a weapons cart? In that case you would still have to lift it on and off, seems like you need a crane anyway.

But the solution to my problem might already exist in types of applications other than aeronautical. Unfortunately i am not as knowledgeable of ground and maritime systems. For example, how do you move heavy shells that feed self-propelled howitzers...is there some sort of conveyor belt?

thanks for any input you might have!

I often come to the forum to look at ways specific problems were solved in the past. This one is a bit tricky and i haven't found anything relevant, so i was wondering if i could solicit help directly.

The project i'm working on requires moving heavy objects through the cabin of an air vehicle. I can't tell you the exact concept, but i can use an example that's close enough. Imagine a C-130 gunship and for some silly reason you have a retractable Hellfire launcher that you can reload from the inside. How do you safely get the missiles from storage to the launcher? It would take more than one person to lift it, and at any rate you wouldn't want to do that in turbulence.

The closest comparable situation i've found is that of the Gunship CH-46 (pic below), but there's no detail of how the anti-tank missiles are moved about; they could also be lightweight enough that they were carried by hand. I'm not so sure about the rockets though.

I thought you could use a small overhead gantry crane maybe. We're not talking about a lot of weight in the big scheme of things. Strap the item, lift it, and push it down the fuselage to where it needs to go. one person could do that. Or maybe it's more like a weapons cart? In that case you would still have to lift it on and off, seems like you need a crane anyway.

But the solution to my problem might already exist in types of applications other than aeronautical. Unfortunately i am not as knowledgeable of ground and maritime systems. For example, how do you move heavy shells that feed self-propelled howitzers...is there some sort of conveyor belt?

thanks for any input you might have!