absence of an illuminated AOA DISAGREE alert, due to a misconfiguration in the MAX’s software that Boeing discovered in 2017 but did not plan to fix until 2020

[...]

“The AOA DISAGREE alert was not correctly enabled during Boeing 737-8 (MAX) development,” the NTSC says. “As a result, it did not appear during flight with the miscalibrated AOA sensor, could not be documented by the flight crew and was therefore not available to help maintenance.”

[...]

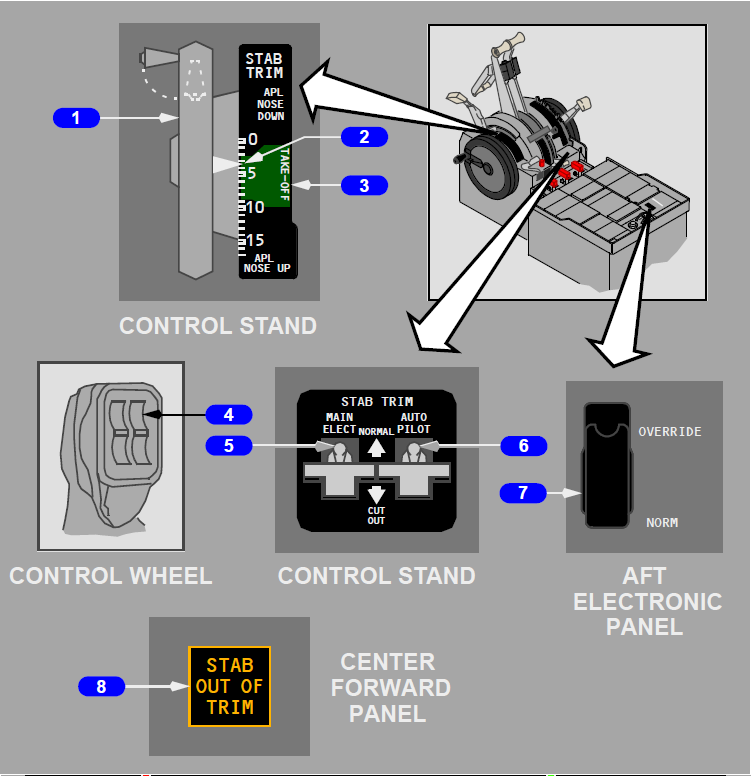

The runaway stabilizer checklist calls for using the cutout switches if other actions, including electric trim inputs, do not stop the runaway condition. On both JT610 and the March 10, 2019, crash of

Ethiopian Airlines Flight 302, another 737-8, pilots used electric trim to counter the MCAS. This interrupted the nose-down stabilizer movements, but faulty AOA data triggered the MCAS repeatedly.

“[Erroneous] MCAS activation does not look like a typical stabilizer runaway, which is continuous uncommanded (runaway) movement of the stabilizer,” the NTSC report says. “During the accident flight, the stabilizer movement was not continuous; the MCAS commands were bounded by the MCAS authority (up to 2.5 deg); the pilots were able to counter the nose-down movement using opposing manual electric trim inputs. . . . After the pilots released the manual electric input and MCAS was reset, there was not another MCAS command for 5 sec.”

There is no evidence of the JT610 crew referring to the runaway-stabilizer checklist or toggling center pedestal-mounted cut-out switches that would have stopped the automatic stabilizer movements. The 737 MAX flight crew operations manual did not contain any information on the MCAS. Boeing determined during the MAX’s development that the information was superfluous based on U.S. Federal Aviation Regulation Part 25.1585 (b), which says, “Information or procedures not directly related to airworthiness or not under the control of the crew must not be included, nor must any procedure that is accepted as basic airmanship.”

The FAA accepted Boeing’s logic, the NTSC report says, adding that the rationale behind the decision “was not formally documented in meeting minutes.”

www.seattletimes.com

www.seattletimes.com