You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

T-X Trainer - Boeing T-7A Red Hawk

- Thread starter flateric

- Start date

- Joined

- 16 April 2008

- Messages

- 8,419

- Reaction score

- 10,432

Good article here about the impact of Black Diamond on the aircraft assembly process.:

http://breakingdefense.com/2016/09/boeing-saab-unveil-t-x-entry-program-goes-straight-to-production/?utm_source=feedburner&utm_medium=feed&utm_campaign=Feed%3A+BreakingDefense+%28Breaking+Defense%29

Also, these interesting tidbits:

So that probably explains the afterburner -- they are designing for the low-cost combat aircraft market as well.

http://breakingdefense.com/2016/09/boeing-saab-unveil-t-x-entry-program-goes-straight-to-production/?utm_source=feedburner&utm_medium=feed&utm_campaign=Feed%3A+BreakingDefense+%28Breaking+Defense%29

Also, these interesting tidbits:

The plane, which can be modified to accept two hard points per wing (it’s not a requirement to have any), can be refueled in flight just behind the flight instructor’s position, Davis said.

So that probably explains the afterburner -- they are designing for the low-cost combat aircraft market as well.

- Joined

- 16 April 2008

- Messages

- 8,419

- Reaction score

- 10,432

Trident said:... which may be the answer to the pitot question - one of the two completed airframes has it, and they revealed the example which doesn't.

Could be. Also, at around 0:15 in the video, you can see the nosecone with the pitot sitting on the ground in front of the aircraft. So it looks like an easy swap.

Good point! So the one starring in the video may be the one shown to the public after all.

With hindsight (and having looked at the silhouette frame again) I think the issue is that it shows more than one T-X, sort of breaking formation. I don't think the 3D models are deliberately distorted or modified.

While we're on the subject of anticipatory comments:

http://www.secretprojects.co.uk/forum/index.php/topic,13751.msg288542.html#msg288542

... indeed!

TomS said:Hey, I knew the various images didn't match up.

http://www.secretprojects.co.uk/forum/index.php/topic,13751.msg288454.html#msg288454

With hindsight (and having looked at the silhouette frame again) I think the issue is that it shows more than one T-X, sort of breaking formation. I don't think the 3D models are deliberately distorted or modified.

While we're on the subject of anticipatory comments:

http://www.secretprojects.co.uk/forum/index.php/topic,13751.msg288542.html#msg288542

... indeed!

Somewhat nice looking. From above and behind see some super hornet in it, a little bit of alpha jet, t-50, and m-346 and scorpion. Fairly conventional, why such secrecy. On the appearance for such conventional looking designs? Couldn't we have gotten some sketches months ago?

Why no forward fuselage chine shaping, would that have severely affected cost? Make some attempts to lower frontal rc reflection could have done more to make it more appealing to operators needing low cost jet since they are going to market it globally anyway.

Doesn't look like they are going to beat Northrop on cost based on what seen so far, but just my opinion.

Why no forward fuselage chine shaping, would that have severely affected cost? Make some attempts to lower frontal rc reflection could have done more to make it more appealing to operators needing low cost jet since they are going to market it globally anyway.

Doesn't look like they are going to beat Northrop on cost based on what seen so far, but just my opinion.

- Joined

- 1 May 2007

- Messages

- 2,460

- Reaction score

- 1,454

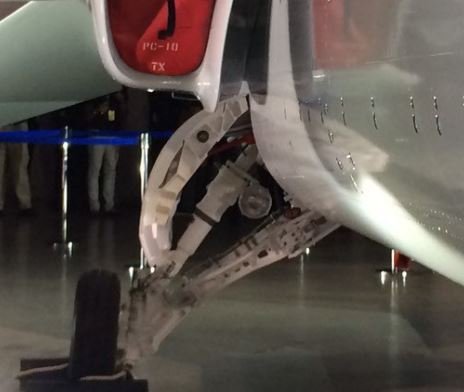

TomS said:Air Force magazine confirms the MLG and nose gear are both from the F-16.

Hmmm, interesting... I wonder, if Boeing beats LM to the contract, if LM will retaliate by trying to stop Boeing using the F-16 U/C...

cheers,

Robin.

A few more thoughts:

1. Twin tails - weight is a disadvantage, but it offers the opportunity to do away with a separate airbrake, even with a F-16/Su-27-style single TE moving surface. This may sound like a fairly minor benefit, but it frees up the fuselage spine for a refueling receptacle (T-100, I'm looking at you).

2. F-16 gear - weird. As someone else has already noted, it is likely to be oversized and overweight. While borrowing landing gear assemblies from established donor aircraft for prototypes is definitely not unusual, changing to a bespoke design later seems strangely at odds with Boeing's pitch that the aircraft is essentially production-representative.

3. What could possibly be so secret about the ejection seats?! I mean, K-36s would be a tough sell in the current political climate - so much so that I can't see them having gone there in the first place, however. Excepting that, though - what's in a seat?

1. Twin tails - weight is a disadvantage, but it offers the opportunity to do away with a separate airbrake, even with a F-16/Su-27-style single TE moving surface. This may sound like a fairly minor benefit, but it frees up the fuselage spine for a refueling receptacle (T-100, I'm looking at you).

2. F-16 gear - weird. As someone else has already noted, it is likely to be oversized and overweight. While borrowing landing gear assemblies from established donor aircraft for prototypes is definitely not unusual, changing to a bespoke design later seems strangely at odds with Boeing's pitch that the aircraft is essentially production-representative.

3. What could possibly be so secret about the ejection seats?! I mean, K-36s would be a tough sell in the current political climate - so much so that I can't see them having gone there in the first place, however. Excepting that, though - what's in a seat?

- Joined

- 27 December 2005

- Messages

- 16,495

- Reaction score

- 19,294

Second airframe for structural testing, I believe.

NUSNA_Moebius

I really should change my personal text

- Joined

- 26 May 2012

- Messages

- 216

- Reaction score

- 105

Personally I think it looks a bit fat and ungainly like the Scorpion with the small mid-mounted intakes. However, aeronautical science isn't about looks, unless you're the X-32 (even though it failed in many other ways). Having the wing so high up I guess should provide a fair amount of longitudinal stability, good for the refueling training mission, but I wonder how it effects the aircraft's roll moment. Going with twin tails was certainly unexpected, but it just brings the aircraft more in line with the F-35 and F-22 for pilots, and added yaw authority at higher alpha. As someone mentioned earlier, it means built-in airbrakes too. I just figured the second tail wasn't worth the extra hydraulics, structure, and therefore weight + cost.

Also I can't help but comment on how confident Boeing is here, pushing the idea that they are ready for production, with a second airframe on the way as well as the large set of serial numbers they currently have reserved for EMDs. Confidence is good, and the Black Diamond initiative certainly is interesting, which means a loss for Boeing will likely be an even bigger blow. At least they'll have the non-US market, but will still have to compete with the current crop of TX competitors regardless.

Also I can't help but comment on how confident Boeing is here, pushing the idea that they are ready for production, with a second airframe on the way as well as the large set of serial numbers they currently have reserved for EMDs. Confidence is good, and the Black Diamond initiative certainly is interesting, which means a loss for Boeing will likely be an even bigger blow. At least they'll have the non-US market, but will still have to compete with the current crop of TX competitors regardless.

- Joined

- 16 April 2008

- Messages

- 8,419

- Reaction score

- 10,432

Trident said:2. F-16 gear - weird. As someone else has already noted, it is likely to be oversized and overweight. While borrowing landing gear assemblies from established donor aircraft for prototypes is definitely not unusual, changing to a bespoke design later seems strangely at odds with Boeing's pitch that the aircraft is essentially production-representative.

3. What could possibly be so secret about the ejection seats?! I mean, K-36s would be a tough sell in the current political climate - so much so that I can't see them having gone there in the first place, however. Excepting that, though - what's in a seat?

On the gear, could be insurance against hard landings by student pilots? (To answer a question someone else asked, the actual gear design belongs to the government, so I don't think LM could interfere with that.)

As to the seats, it might be something else on the seats. Maybe cameras to record the trainee pilot in the cockpit for later playback. That could fit with how tightly integrated the plane is said to be with the ground training systems.

- Joined

- 1 April 2006

- Messages

- 10,741

- Reaction score

- 6,801

https://www.youtube.com/watch?v=amiJwedNJYM

Attachments

-

![Boeing T-X Takes to the Sky.mp4_snapshot_01.00_[2016.09.13_23.57.21].jpg](/data/attachments/125/125973-936e18f36f2500237d559ba47c70d379.jpg) Boeing T-X Takes to the Sky.mp4_snapshot_01.00_[2016.09.13_23.57.21].jpg20.4 KB · Views: 398

Boeing T-X Takes to the Sky.mp4_snapshot_01.00_[2016.09.13_23.57.21].jpg20.4 KB · Views: 398 -

![Boeing T-X Takes to the Sky.mp4_snapshot_01.03_[2016.09.13_23.58.35].jpg](/data/attachments/125/125974-4920228fc15c3ec78d12f7dfbae3f24d.jpg) Boeing T-X Takes to the Sky.mp4_snapshot_01.03_[2016.09.13_23.58.35].jpg26.9 KB · Views: 410

Boeing T-X Takes to the Sky.mp4_snapshot_01.03_[2016.09.13_23.58.35].jpg26.9 KB · Views: 410 -

![Boeing T-X Takes to the Sky.mp4_snapshot_01.26_[2016.09.13_23.59.39].jpg](/data/attachments/125/125975-69c740c15beb86cc2b147f80f68d979d.jpg) Boeing T-X Takes to the Sky.mp4_snapshot_01.26_[2016.09.13_23.59.39].jpg33.4 KB · Views: 411

Boeing T-X Takes to the Sky.mp4_snapshot_01.26_[2016.09.13_23.59.39].jpg33.4 KB · Views: 411 -

![Boeing T-X Takes to the Sky.mp4_snapshot_00.14_[2016.09.13_23.54.04].jpg](/data/attachments/125/125976-18ef85df0f2a2a82ad8566896c811e15.jpg) Boeing T-X Takes to the Sky.mp4_snapshot_00.14_[2016.09.13_23.54.04].jpg40.7 KB · Views: 406

Boeing T-X Takes to the Sky.mp4_snapshot_00.14_[2016.09.13_23.54.04].jpg40.7 KB · Views: 406

- Joined

- 2 August 2006

- Messages

- 3,179

- Reaction score

- 1,167

Trident said:A few more thoughts:

1. Twin tails - weight is a disadvantage, but it offers the opportunity to do away with a separate airbrake, even with a F-16/Su-27-style single TE moving surface. This may sound like a fairly minor benefit, but it frees up the fuselage spine for a refueling receptacle (T-100, I'm looking at you).

2. F-16 gear - weird. As someone else has already noted, it is likely to be oversized and overweight. While borrowing landing gear assemblies from established donor aircraft for prototypes is definitely not unusual, changing to a bespoke design later seems strangely at odds with Boeing's pitch that the aircraft is essentially production-representative.

3. What could possibly be so secret about the ejection seats?! I mean, K-36s would be a tough sell in the current political climate - so much so that I can't see them having gone there in the first place, however. Excepting that, though - what's in a seat?

While the twin tails are a weight and drag disadvantage, they help reduce the chance of entering a spin at high alpha. It will be interesting to see what the performance specs are compared to Northrop's design. It seems to me Northrop is competing on low cost, LM is competing on top end performance and Boeing is going for top end performance with lower cost (Black Diamond). I don't see the T-100 as really having a chance, as the T-100 is based on a Russian design and similar to what the Chinese also fly.

I also thought the F-16 landing gear was an odd choice, unless they are also planning on adding a lower cost combat aircraft later (more hard points, greater weight) and I can't think of another landing gear design that would meet the packaging requirements for the design.

One last thing; Of all the designs, I think this would look the best in the Thunderbirds paint scheme, as I haven't any doubt the TX will be replacing F-16s as their plane of choice once they really start being retired.

It really looks like an OUTDATED DESIGN sorry, just strikes me as a trainer project that Saab or Boeing has on a shelf for 25 years and shook the dust off it for this competition.

The design features really date from 20-30 years prior including the landing gear design. The landing gear does not look too be to big at all for the aircraft, but as others have noticed borrowed from the f-16.

The whole thing just smacks of an older design.

A 30 year old design that looks like a direct T-50 competitor that has been warmed over for this competition. Where is the innovation? Externally the airframe is very dated looking. This is what 21st century pilots are training in for the next 50 years? A Boeing/Saab partnership could have done much better than this and a little more innovation could have expanded the possibilities for the future.

At least the Northrop design has a few innovations added to the basic T-38 design, and also looks alot leaner, lighter and more affordable.

The design features really date from 20-30 years prior including the landing gear design. The landing gear does not look too be to big at all for the aircraft, but as others have noticed borrowed from the f-16.

The whole thing just smacks of an older design.

A 30 year old design that looks like a direct T-50 competitor that has been warmed over for this competition. Where is the innovation? Externally the airframe is very dated looking. This is what 21st century pilots are training in for the next 50 years? A Boeing/Saab partnership could have done much better than this and a little more innovation could have expanded the possibilities for the future.

At least the Northrop design has a few innovations added to the basic T-38 design, and also looks alot leaner, lighter and more affordable.

- Joined

- 2 August 2006

- Messages

- 3,179

- Reaction score

- 1,167

kcran567 said:It really looks like an OUTDATED DESIGN sorry, just strikes me as a trainer project that Saab or Boeing has on a shelf for 25 years and shook the dust off it for this competition.

The design features really date from 15-20 years prior including the landig gear design. The landing gear does not look to be to big at all for the aircraft, but as others have noticed borrowed from the f-16.

The whole thing just smacks of an older design.

At least the Northrop design has a few innovations added to the basic T-38 design, and also looks alot leaner, lighter and more affordable.

That's because you don't understand aerodynamics. Aerodynamics today is the same as it was 25 years ago. You aren't going to go tailless, have thrust vectoring, something stealthy, etc, because all you are doing is adding unnecessary cost and you guarantee you will lose. None of the most advanced aerodynamic and control technologies are required to meet the specifications. The aerospace companies would have been insanely stupid to design what you wanted to see. Aircraft are designed by the mission requirements, not the wishes of fanboys (And I am a fanboy too, who loves advanced designs as well, which is why I am still drooling through <u>Flying Wings and Radical Things</u>.

The difference and advanced technology is in the training system itself. That's where these designs are vastly different from anything designed before; in the cockpit where it will matter most. Also, there is no way the T-38 had anywhere near the alpha capability that any of these designs have.

marauder2048

"I should really just relax"

- Joined

- 19 November 2013

- Messages

- 3,157

- Reaction score

- 776

Sundog said:Boeing is going for top end performance with lower cost (Black Diamond).

Which is contradicted by:

The aircraft was designed to meet the "threshold" requirements for T-X, and if the Air Force does not give extra credit for capability beyond that, "we're going to win," Davis said.

http://www.airforcemag.com/Features/Pages/2016/September%202016/Boeing-Unveils-Twin-Tail-T-X.aspx

bring_it_on

I really should change my personal text

- Joined

- 4 July 2013

- Messages

- 3,123

- Reaction score

- 2,240

and if the Air Force does not give extra credit for capability beyond that, "we're going to win," Davis said.

Thats a strange thing to say when the draft RFP was released months ago unless of course you are trying to play it safe.

Sundog said:kcran567 said:It really looks like an OUTDATED DESIGN sorry, just strikes me as a trainer project that Saab or Boeing has on a shelf for 25 years and shook the dust off it for this competition.

The design features really date from 15-20 years prior including the landig gear design. The landing gear does not look to be to big at all for the aircraft, but as others have noticed borrowed from the f-16.

The whole thing just smacks of an older design.

At least the Northrop design has a few innovations added to the basic T-38 design, and also looks alot leaner, lighter and more affordable.

That's because you don't understand aerodynamics. Aerodynamics today is the same as it was 25 years ago. You aren't going to go tailless, have thrust vectoring, something stealthy, etc, because all you are doing is adding unnecessary cost and you guarantee you will lose. None of the most advanced aerodynamic and control technologies are required to meet the specifications. The aerospace companies would have been insanely stupid to design what you wanted to see. Aircraft are designed by the mission requirements, not the wishes of fanboys (And I am a fanboy too, who loves advanced designs as well, which is why I am still drooling through <u>Flying Wings and Radical Things</u>.)

The difference and advanced technology is in the training system itself. That's where these designs are vastly different from anything designed before; in the cockpit where it will matter most. Also, there is no way the T-38 had anywhere near the alpha capability that any of these designs have.

Am also interested in manufacturing techniques and materials. Looks conventional and similar to the Lockheed Martin T-50 overall except for the twin tails. If the design itself, manufacturing, and materials are tried and true and 20-30 years dated, where is the cost savings compared to the others? I see what you are saying about the cockpit training systems, but technology is moving so fast in this area and software is there really going to be that big a difference in cockpit simulation capability? Sorry, just a little disappointed was expecting more.

- Joined

- 3 June 2011

- Messages

- 17,346

- Reaction score

- 9,102

kcran567 said:If the design itself, manufacturing, and materials are tried and true and 20-30 years dated, where is the cost savings compared to the others?

How do you know what manufacturing techniques they're using? As for the design, all you know is what it looks like on the outside. I guarantee you it doesn't look like a 30 year old aircraft under the OML.

- Joined

- 18 October 2006

- Messages

- 3,884

- Reaction score

- 3,753

I suspect that the test pitot came off for the rollout so the aircraft was "EMD" ready.TomS said:Interesting that it had a test pitot before the rolled in into the paint shop. Wind tunnel testing?

- Joined

- 16 April 2008

- Messages

- 8,419

- Reaction score

- 10,432

sferrin said:kcran567 said:If the design itself, manufacturing, and materials are tried and true and 20-30 years dated, where is the cost savings compared to the others?

How do you know what manufacturing techniques they're using? As for the design, all you know is what it looks like on the outside. I guarantee you it doesn't look like a 30 year old aircraft under the OML.

I posted an article earlier that talks about construction techniques. They're stressing a radical reduction in "touch labor" in the manufacturing process, with an example of cockpit assembly, which they say takes about one fifth the time of conventional techniques. If that figure is accurate, that's a radical change.

- Joined

- 2 August 2006

- Messages

- 3,179

- Reaction score

- 1,167

kcran567 said:Am also interested in manufacturing techniques and materials. Looks conventional and similar to the Lockheed Martin T-50 overall except for the twin tails. If the design itself, manufacturing, and materials are tried and true and 20-30 years dated, where is the cost savings compared to the others? I see what you are saying about the cockpit training systems, but technology is moving so fast in this area and software is there really going to be that big a difference in cockpit simulation capability? Sorry, just a little disappointed was expecting more.

From this article at Breaking Defense posted upthread by TomS;

“It is a production jet at this stage,” averred Darryl Davis, president of Boeing’s Phantom Works, standing in front of a second jet already being subjected to structural proof tests. The two companies are building a plane with very little touch labor and are using advanced adhesives, 3-D printing (additive manufacturing to the faithful) and other techniques to “break the cost curve,” Davis told reporters after the unveiling this morning. Bending the cost curve is, of course, Air Force Secretary Deborah Lee James’ effort to rein in development and procurement costs.

Davis, whose Phantom Works includes the luridly famous Black Diamond production experiments, said production knowledge gleaned from both companies’ commercial and defense experience meant they would rely on “orders of magnitude less touch labor.”

As an example of the advanced techniques being employed, Program Manager Ted Torgerson walked over to the plane’s cockpit. Currently, a cockpit takes about six weeks to build and requires expensive equipment to hold it and the materials needed to build it. We’ve taken a six-week process and brought it down to eight days,” Torgerson said.

- Joined

- 2 August 2006

- Messages

- 3,179

- Reaction score

- 1,167

With regard to the single tail versus twin tail argument, the Air Force Magazine has this to say about that trade-off;

The twin tails also allow the airplane to be shorter, which reduces weight and cost, Davis said.

It's a 20-30 year old design on the outside, but it meets the basic aerodynamic requirements, meets the cargo hauling requirements, there is no need for a more innovative design. What really matters is the technology that's on the inside.

We can just build it with less touch labor and use our advanced adhesives.

We can just build it with less touch labor and use our advanced adhesives.

Attachments

lantinian

ACCESS: Top Secret

- Joined

- 24 March 2007

- Messages

- 538

- Reaction score

- 127

Definitely my favorite T-Xso far. I haven't seen this discussed but I think the twin tales will allow for a much larger AoA envelope of training and better prepare pilots for the F-22/F-35

There is a nice discussion on the Check Six podcast a few weeks ago mostly related to the Northrop T-X and they were right when they said that Boing will try the hardest to win

Aviation Week's Check 6 Podcast: Putting Odds on the T-X Bidders

https://overcast.fm/+BlsrqRPZs

I think what Boing is trying to do is

- meet the performance requirements but exceed them

- show very low support & production costs, which given program length is a win

- innovate on the side of the pilot training program itself

What I wander is if the partnership with SAAB will guarantee any orders from Swedish government or at least increased the chance of doing so?

If they say, this is so production ready, does it mean they can market this aircraft and sell it even if they don't win the competition?

There is a nice discussion on the Check Six podcast a few weeks ago mostly related to the Northrop T-X and they were right when they said that Boing will try the hardest to win

Aviation Week's Check 6 Podcast: Putting Odds on the T-X Bidders

https://overcast.fm/+BlsrqRPZs

I think what Boing is trying to do is

- meet the performance requirements but exceed them

- show very low support & production costs, which given program length is a win

- innovate on the side of the pilot training program itself

What I wander is if the partnership with SAAB will guarantee any orders from Swedish government or at least increased the chance of doing so?

If they say, this is so production ready, does it mean they can market this aircraft and sell it even if they don't win the competition?

- Joined

- 16 April 2008

- Messages

- 8,419

- Reaction score

- 10,432

vmaddux said:I have it on good authority from one of the sub contractors, the the landing gear is from a Gripen , not an F-16. which makes more sense then Boeing getting landing gear fro Lockheed.

Sorry, but that's clearly wrong. Just look at the Gripen's landing gear; they don't look like the ones seen on the Boeing T-X at all.

First pic is Gripen's, second is F-16, third is T-X. Resemblance between 2 and 3 is unmistakable.

Attachments

- Joined

- 21 December 2006

- Messages

- 1,133

- Reaction score

- 618

If making it appear more 'all American' than it really is gets a 300 order subcontract I am sure SAAB will be happy.

Depending on how the election goes, 'American jobs' could be a deciding factor. Appearances might matter, especially against a Russo/Italian and South Korean design.

Re undercarriage, the tyres/tires (one is right!) are a significant expense, as is maintenance of oleos etc. Student pilots may slam it down hard. Having a pile of spare F16 tyres and predictable maintenance costs/trained staff (and American jobs in the supply chain) could offer a significant potential saving, and a more realistic/believable LCC estimate.

Of the four candidates this looks the most lively performer/export fighter basis. Reducing risk/cost will matter as other designs seem focussed on those aspects.

Depending on how the election goes, 'American jobs' could be a deciding factor. Appearances might matter, especially against a Russo/Italian and South Korean design.

Re undercarriage, the tyres/tires (one is right!) are a significant expense, as is maintenance of oleos etc. Student pilots may slam it down hard. Having a pile of spare F16 tyres and predictable maintenance costs/trained staff (and American jobs in the supply chain) could offer a significant potential saving, and a more realistic/believable LCC estimate.

Of the four candidates this looks the most lively performer/export fighter basis. Reducing risk/cost will matter as other designs seem focussed on those aspects.

flanker

ACCESS: Top Secret

- Joined

- 20 March 2008

- Messages

- 933

- Reaction score

- 240

Wow, that is almost uncanny.

Knowing Boeing, here is probably what happened with the cockpit actually; It was subcontracted and the subcontractor then subcontracted it a few dozen times all over the world. Then it was assembled at the main subcontractor in 7 weeks. Then it was shipped to Boeing and they used eight days to place a Boeing sticker in it. Voila, eight days.

Sundog said:kcran567 said:Am also interested in manufacturing techniques and materials. Looks conventional and similar to the Lockheed Martin T-50 overall except for the twin tails. If the design itself, manufacturing, and materials are tried and true and 20-30 years dated, where is the cost savings compared to the others? I see what you are saying about the cockpit training systems, but technology is moving so fast in this area and software is there really going to be that big a difference in cockpit simulation capability? Sorry, just a little disappointed was expecting more.

From this article at Breaking Defense posted upthread by TomS;

“It is a production jet at this stage,” averred Darryl Davis, president of Boeing’s Phantom Works, standing in front of a second jet already being subjected to structural proof tests. The two companies are building a plane with very little touch labor and are using advanced adhesives, 3-D printing (additive manufacturing to the faithful) and other techniques to “break the cost curve,” Davis told reporters after the unveiling this morning. Bending the cost curve is, of course, Air Force Secretary Deborah Lee James’ effort to rein in development and procurement costs.

Davis, whose Phantom Works includes the luridly famous Black Diamond production experiments, said production knowledge gleaned from both companies’ commercial and defense experience meant they would rely on “orders of magnitude less touch labor.”

As an example of the advanced techniques being employed, Program Manager Ted Torgerson walked over to the plane’s cockpit. Currently, a cockpit takes about six weeks to build and requires expensive equipment to hold it and the materials needed to build it. We’ve taken a six-week process and brought it down to eight days,” Torgerson said.

Knowing Boeing, here is probably what happened with the cockpit actually; It was subcontracted and the subcontractor then subcontracted it a few dozen times all over the world. Then it was assembled at the main subcontractor in 7 weeks. Then it was shipped to Boeing and they used eight days to place a Boeing sticker in it. Voila, eight days.

lantinian

ACCESS: Top Secret

- Joined

- 24 March 2007

- Messages

- 538

- Reaction score

- 127

Whole front part, flat nose, cabin, intakes, lerx and even wings to a fair extent are quite similar to SAAB's Eurotrainer concept. (rear part is different, of course) Which is probably why Boeing went with SAAB in the first place. They needed someone who had a design half-ready, and who could finish it quickly, when properly funded.

In other "news", comparing top/side drawing from the Boeing animation with top/side views of T-50, trying to scale them around F404 engine and cockpit elements - yields interesting results. It seems to me Boeing's plane is a bit longer, say half a foot from nose to end of engine nozzle, plus the additional elevator overhang. Boeing plane also seems to have wingspan half a foot shorther. T-50 has its tail positioned slightly more aft, while its lerx/wings are positioned roughly a foot closer to nose tip.

I'd say there's little chance Boeing's plane is under 6 tons empty...

In other "news", comparing top/side drawing from the Boeing animation with top/side views of T-50, trying to scale them around F404 engine and cockpit elements - yields interesting results. It seems to me Boeing's plane is a bit longer, say half a foot from nose to end of engine nozzle, plus the additional elevator overhang. Boeing plane also seems to have wingspan half a foot shorther. T-50 has its tail positioned slightly more aft, while its lerx/wings are positioned roughly a foot closer to nose tip.

I'd say there's little chance Boeing's plane is under 6 tons empty...

NeilChapman

Interested 3rd party

- Joined

- 14 December 2015

- Messages

- 1,284

- Reaction score

- 485

marauder2048 said:Sundog said:Boeing is going for top end performance with lower cost (Black Diamond).

Which is contradicted by:

The aircraft was designed to meet the "threshold" requirements for T-X, and if the Air Force does not give extra credit for capability beyond that, "we're going to win," Davis said.

http://www.airforcemag.com/Features/Pages/2016/September%202016/Boeing-Unveils-Twin-Tail-T-X.aspx

If I understand correctly, Black Diamond only makes a difference in acquisition cost. With a US$15-25Million airframe I don't see this making a significant difference in costs over the life of the program (~US$20Billion/30 years?) w/350 aircraft.

What will make a significant difference is the upgrade/maintenance costs over 700 airframes or more (LM states there are 150 T-50's flying today) where dev costs can be shared. If Boeing/SAAB or LM can make this financial case (depending on the % common T-50A w/other variants) then it may be difficult for NG to win this argument as it looks as though NG has not focused on the inexpensive fighter market. This is really the only reason I can see why the Boeing/SAAB prototype has a wet engine - unless their models show they can't meet the performance metrics w/o it (mass) which could be bad.

But first you have to meet the 'T-X program' requirements. Unfortunately I know of no way for us to look into the GBTS offerings of each vendor. Perhaps there are members of this forum that have more insight into these offerings and understand the differentiators.

Responding to the "threshold" statement, seems to me that it depends on which threshold is being referenced. Could be they're talking about the upper threshold with performance and lower threshold with operating cost.

e.g If flight hour cost expectation is US$18k and they meet that cost then they expect they're OK. If NG's N400 flight hour cost is US$10K then Boeing is hoping that NG would not get credit for that reduction.

It sure looks like Boeing went all in on this though. Pretty cool to see a mini-f18.

--

On another note...

Now that the major players have shown their hand let's see some video of that little beast flying NG! Get it on!

XP67_Moonbat

ACCESS: Top Secret

- Joined

- 16 January 2008

- Messages

- 2,246

- Reaction score

- 380

Actually, Doolyii, there sorta was. I refer you to Tony Chong's book on Northrop projects.

So evidently this thing is held together with adhesives, and "tools" are not being used according to Boeing: no fasteners, rivets, etc. I'm skeptical to say the least.

I'm sure when delivered it may work OK at first but what happens when it starts to delaminate due to combat stresses or if sitting in the hot desert sun.

http://www.defensenews.com/articles/t-x-trainer-air-force-boeing

Some comments and observations:

"These processes enable Boeing to assemble the aircraft without any tools, Davis said."

And the Media was stupid enough to print it, or else it's made out of Play Dough.

....you don't get to define what is a tool and what isn't. I suppose Scotty beams them into place. The no tools used statement is utter BS.

they main airframe is glued together... the only tool is a caulking gun & clamps.

What they meant is a lack of fasteners , no rivet guns, wrenches, ratchets or hammers.

Just a big gluegun & clamps... also a drivethru autoclave

I'm sure when delivered it may work OK at first but what happens when it starts to delaminate due to combat stresses or if sitting in the hot desert sun.

http://www.defensenews.com/articles/t-x-trainer-air-force-boeing

Some comments and observations:

"These processes enable Boeing to assemble the aircraft without any tools, Davis said."

And the Media was stupid enough to print it, or else it's made out of Play Dough.

....you don't get to define what is a tool and what isn't. I suppose Scotty beams them into place. The no tools used statement is utter BS.

they main airframe is glued together... the only tool is a caulking gun & clamps.

What they meant is a lack of fasteners , no rivet guns, wrenches, ratchets or hammers.

Just a big gluegun & clamps... also a drivethru autoclave

- Joined

- 16 April 2008

- Messages

- 8,419

- Reaction score

- 10,432

The actual quote was "no hard tooling" which mean something completely different from "without tools." It means none of the specially built dedicated stands and jigs we associate with a normal aircraft assembly line.

Just looking at the photos of the unpainted aircraft shows that your "no fasteners" rant is off the mark; there are rivets everywhere. In fact, Boeing has said that there is relatively little composite structure in the aircraft, though there are some complex shapes built using 3D printing.

Just looking at the photos of the unpainted aircraft shows that your "no fasteners" rant is off the mark; there are rivets everywhere. In fact, Boeing has said that there is relatively little composite structure in the aircraft, though there are some complex shapes built using 3D printing.

marauder2048

"I should really just relax"

- Joined

- 19 November 2013

- Messages

- 3,157

- Reaction score

- 776

Harrier said:Depending on how the election goes, 'American jobs' could be a deciding factor. Appearances might matter, especially against a Russo/Italian and South Korean design.

This is just silly. GAO alone sure as hell won't take "appearances" into account in evaluating the inevitable protest.

Similar threads

-

-

MRV, MIRV, MARV, and FOBS Projects

- Started by moin1900

- Replies: 7

-

-

-

USAF to Retire B-1, B-2 in Early 2030s as B-21 Comes On-Line

- Started by flateric

- Replies: 338