- Joined

- 15 January 2021

- Messages

- 232

- Reaction score

- 755

1. The F119 fan pressure ratio, like many of the engine’s specifications, has not been publicly released, to my knowledgeThanks! Very interesting. Some comments below.

I've been trying to extrapolate Izd. 30 performance based on open-source data available on other clean-sheet, new-generation Russian engines and demonstrator turbomachinery. As a lower bound, I got the same kind of LP compressor PR. As an aside, if you say 4.2 is only sufficient for at most Mach 1.4 supercruise, what's the PR of the F119 LPC, if that is publicly releasable info? It also has a 3-stage fan, and otherwise does not seem to have especially high stage-PRs compared to the EJ200 with a 4.2 ratio for its LPC.

Worth noting that the KND-924-3 blisk LPC upgrade for the AL-31FM was already supposed to hit a 4.2 ratio 20 years ago. So with advances in the state of the art in the mean time, I expect this to be firmly the lower bound, as mentioned.

It's definitely going to be a 5-stage machine. Other than that, I think this is almost certainly low-balling the HPC PR. From the performance achieved in the civilian PD-14 compressor, various research projects and a 6-stage core upgrade for the ultimate AL-31FM3 that targeted 6.7, i'd expect a PR of at least 6.2 (like the 5-stage EJ200). Possibly as high as 7.0 as an upper bound (but that is pushing it on OPR, leading to high compressor exit temps for an engine behind a supersonic intake).

Might the temperature rise over a machine with a relatively high number of stages and a high PR skew your geometrical method here?

Plausible. My gut instinct is also that the Russians would not go quite as low with BPR as the F414, M88 or F119, given a fairly high emphasis on SFC in their statements about the design. So nearer to 0.4 (akin to the EJ200) than 0.3 or less seems about right.

The rear of the engine schematic looks suspiciously like the legacy AL-31F (nozzle design, AB flame holders, turbine exit cone), so that might be a place holder. When images were first leaked of the LO nozzle on an uninstalled Izd. 30, the interior was censored, obscuring the AB flame holder design and possible LO measures. It's conceivable that these are considered sensitive and therefore not shown.

Fairly safe bet that there will be independent A8/A9 control given the emphasis on supersonic performance - the AL-31F nozzle already had this.

2. Is the Project cross section accurate? Hard to tell. When the F119 cross section was first printed, the inner and outer flow path were split to prevent any geometric analysis by better engineers than me.

3. Could the HP compressor pressure design ratio be higher than the flow path geometry indicates? Yes, the operating line of the compressor is a function of the HP turbine inlet vane area. Making the HPT vane flow area smaller will raise the operating line and increase the HPC pressure ratio. However, this results in the flow Mach number decreasing in the rear stages of the compressor, and pushes the compressor towards stall and typically reduces the compressor efficiency. But, as I said before, the Russians have known to be very good at aerodynamics, so they may have found way to make this work for them.

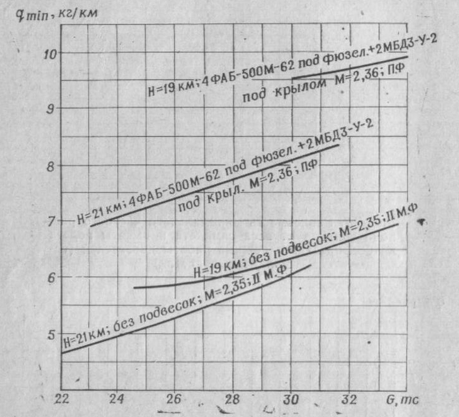

The real challenge for supercruise is to maintain the airflow and engine pressure ratio under increasing ram inlet air temperature. You have to have sufficient Fan pressure ratio for have nozzle exhaust velocity higher than your supersonic airspeed to have forward thrust and enough to overcome drag. As the inlet temperature increases with Mach number, both the LP and HP spools have to turn faster with increasing TIT just to maintain the same airflow and pressure ratio, until you hit the rotor speed and TIT limits, after which your airflow and engine pressure ratio drop off. Having sufficient rotor speed and TIT margin for high inlet temperatures , along with a high Fan Pressure Ratio / Engine Pressure Ratio for high non-reheat exhaust velocity is the key. And very difficult to achieve….