xylstra

I really should change my personal text

- Joined

- 23 October 2018

- Messages

- 79

- Reaction score

- 37

Photographic 'artefact' -or maybe not??

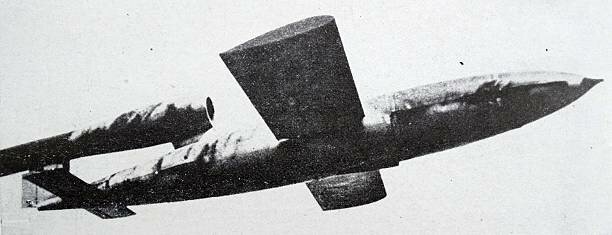

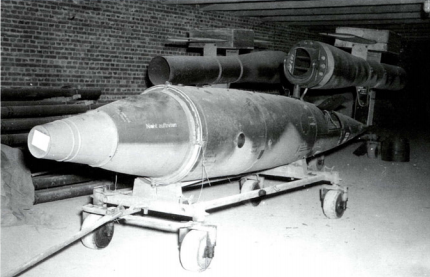

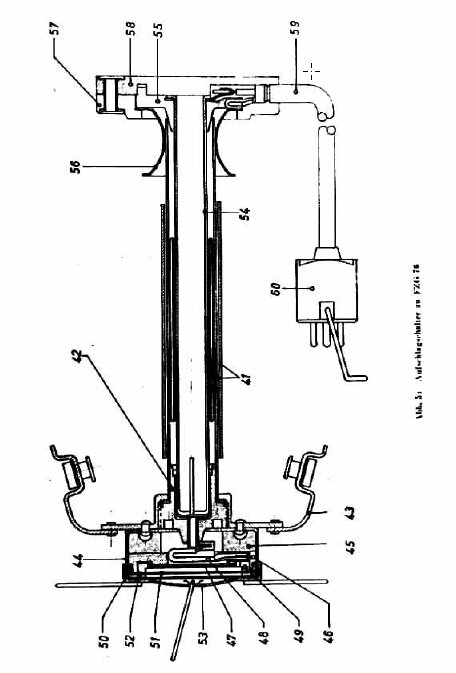

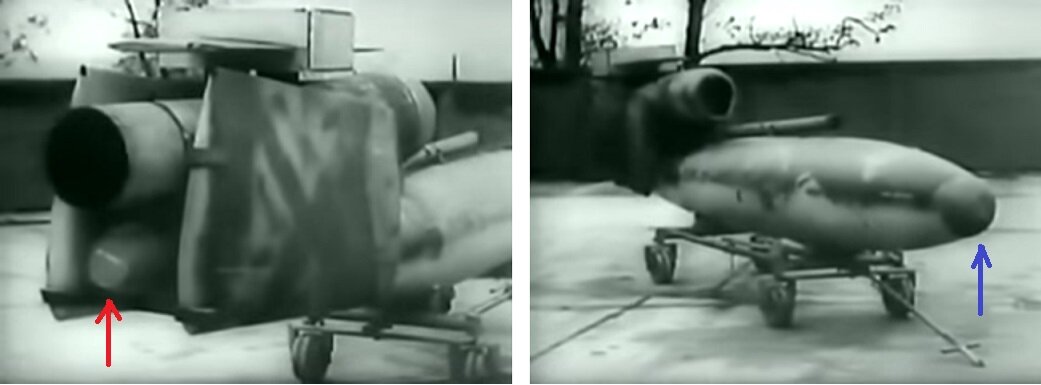

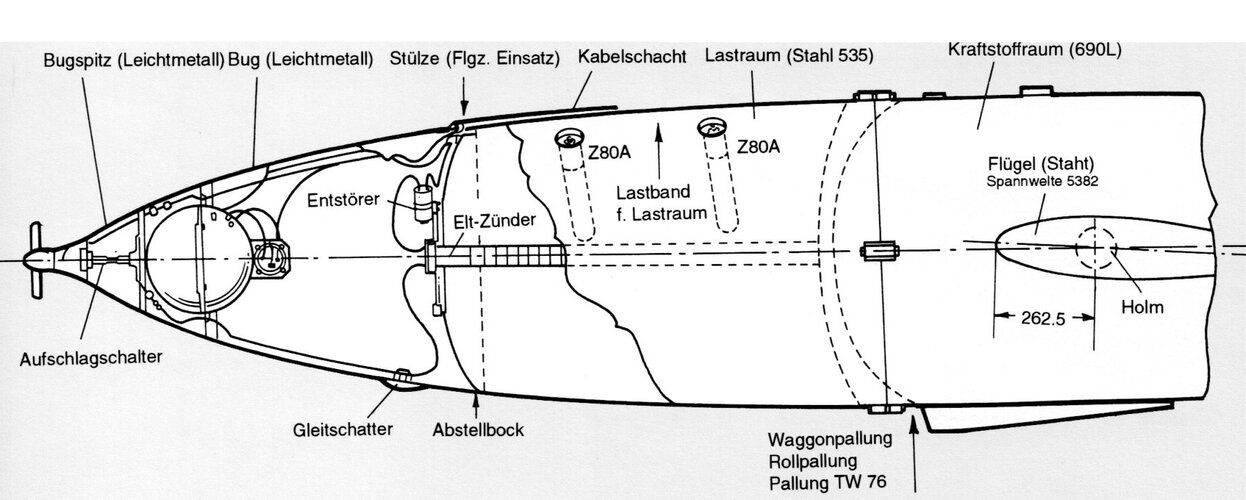

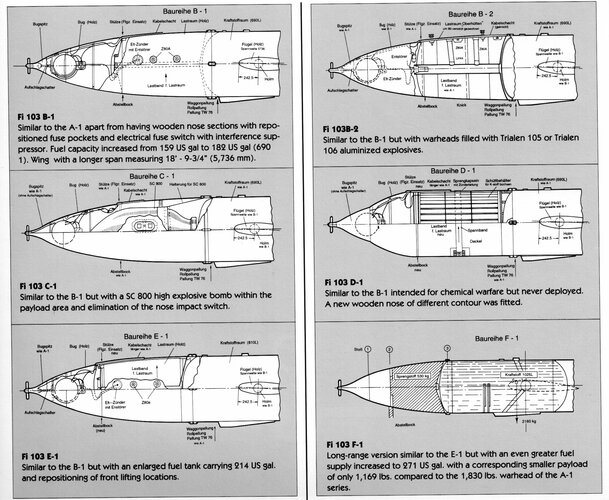

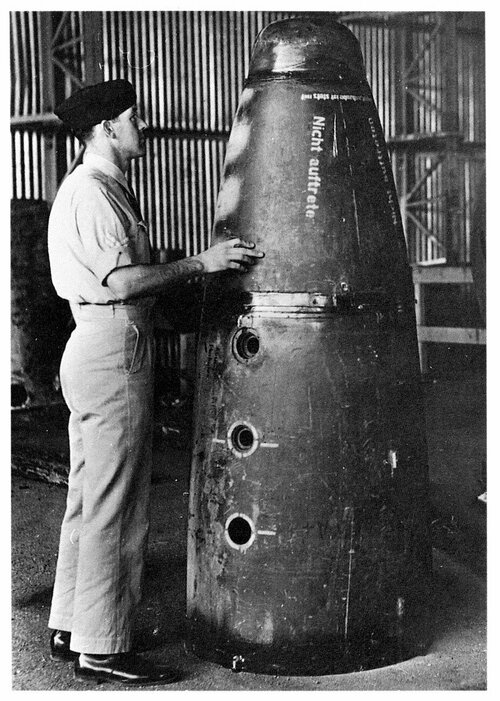

The following is a well recycled picture of a V-1 ground-crew man-handling a V-1 flying bomb on it's ground trolley. Unless my eyes deceive me the characteristic nose profile of the usual V-1 we're all used to seeing is distinctly lacking the normal ogival shape and instead, it looks for all the world like a bucket-shaped protective shield has been placed over the nose. ....or perhaps the factory made design changes to the previous nose-cap? Obviously, at this point in the pre-lauch procedures the Veeder-counter propeller has not been installed until just prior to locking the V1 to the launch ramp.

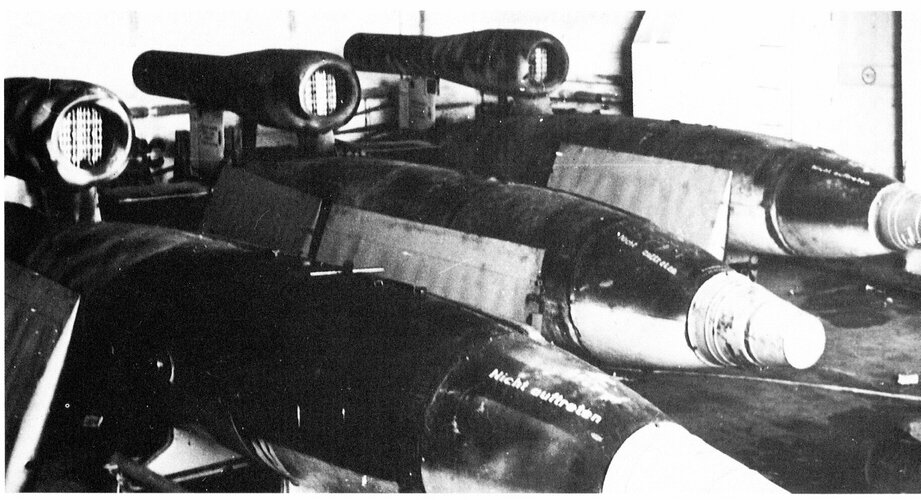

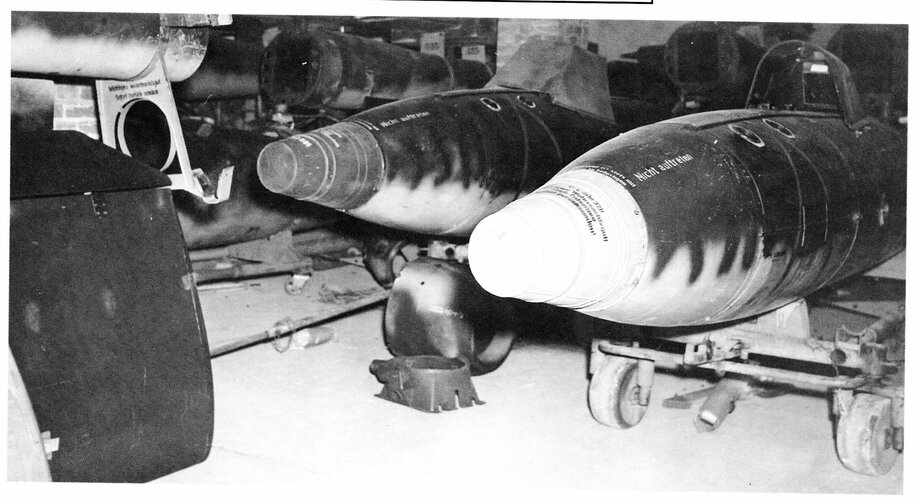

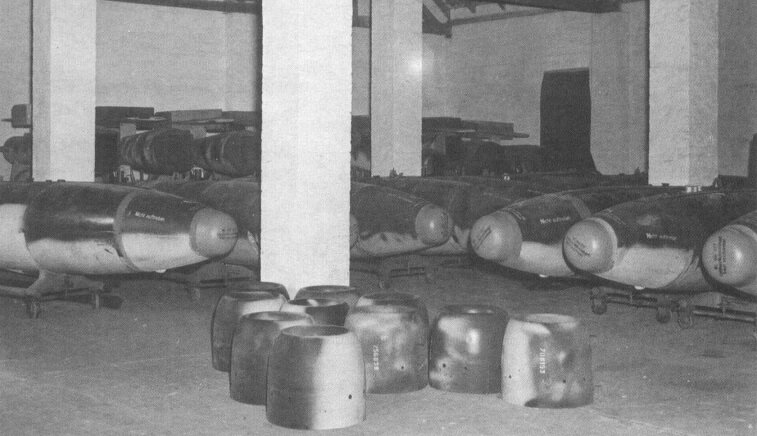

Compare this picture to the more common pictures one usually sees of similar pre-flight ground manoeuvres:

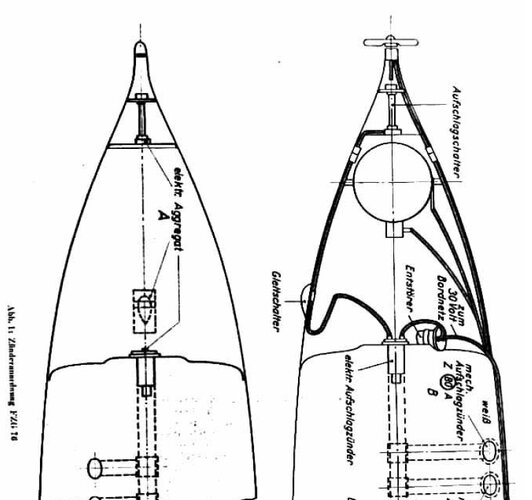

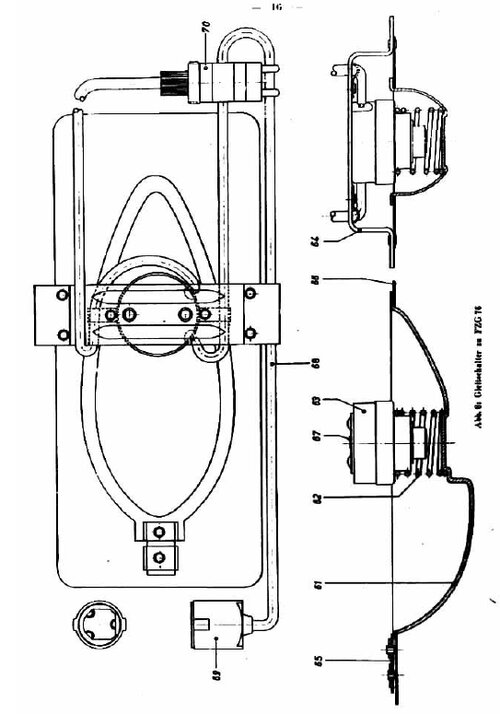

So, the first obvious question: protective nose-cap 'bucket', or not? ....followed by; if "Yes, it's a bucket!" then what was its purpose? Was it purely to prevent mechanical collision damage to the Veeder counter odometer/compass or could it be more subtle, like inhibiting inadvertent magnetisation from the impingement of stray magnetic fields thus preventing rogue deflection of the directional compass-disc achieved by constructing the bucket as a shield made out of Mu-metal? ...and, if this was the case, then when was this procedural change introduced since this is just about the only photo that shows this cover installed, every other picture of a V1 on the ground shows the nose uncovered: early handling procedure subsequently found to be of no merit, then quickly omitted or else found to be necessary and therefore instituted late in the V1 campaign? Anyone know??

As a brief diversion, that mention of de-magnetisation (above) prompts me to comment on the German practice for demagnetising the V1's steel fuselage. How many of you know what this 'process' entailed? Well, just prior to launch the missile was hauled into a wooden building containing no iron within its structure and the de-magnetisation team applied the super-sophisticated, high-tech process of frantically attacking the beast with wooden mallets! Seriously, that's how it was done which also neatly explains why you will see quite a number of pictures of V1's with numerous indentations which heretofore you may have just passed off as handling, transit damage. As but one example, there is a well-known picture of a V1 Having just left the end of the launch pad which displays what appears to be a large longitudinal cleft just behind the nose. The moral of the story: when press-ganging the locals into the de-magnetisation crew don't include the village black-smith!

The following is a well recycled picture of a V-1 ground-crew man-handling a V-1 flying bomb on it's ground trolley. Unless my eyes deceive me the characteristic nose profile of the usual V-1 we're all used to seeing is distinctly lacking the normal ogival shape and instead, it looks for all the world like a bucket-shaped protective shield has been placed over the nose. ....or perhaps the factory made design changes to the previous nose-cap? Obviously, at this point in the pre-lauch procedures the Veeder-counter propeller has not been installed until just prior to locking the V1 to the launch ramp.

Compare this picture to the more common pictures one usually sees of similar pre-flight ground manoeuvres:

So, the first obvious question: protective nose-cap 'bucket', or not? ....followed by; if "Yes, it's a bucket!" then what was its purpose? Was it purely to prevent mechanical collision damage to the Veeder counter odometer/compass or could it be more subtle, like inhibiting inadvertent magnetisation from the impingement of stray magnetic fields thus preventing rogue deflection of the directional compass-disc achieved by constructing the bucket as a shield made out of Mu-metal? ...and, if this was the case, then when was this procedural change introduced since this is just about the only photo that shows this cover installed, every other picture of a V1 on the ground shows the nose uncovered: early handling procedure subsequently found to be of no merit, then quickly omitted or else found to be necessary and therefore instituted late in the V1 campaign? Anyone know??

As a brief diversion, that mention of de-magnetisation (above) prompts me to comment on the German practice for demagnetising the V1's steel fuselage. How many of you know what this 'process' entailed? Well, just prior to launch the missile was hauled into a wooden building containing no iron within its structure and the de-magnetisation team applied the super-sophisticated, high-tech process of frantically attacking the beast with wooden mallets! Seriously, that's how it was done which also neatly explains why you will see quite a number of pictures of V1's with numerous indentations which heretofore you may have just passed off as handling, transit damage. As but one example, there is a well-known picture of a V1 Having just left the end of the launch pad which displays what appears to be a large longitudinal cleft just behind the nose. The moral of the story: when press-ganging the locals into the de-magnetisation crew don't include the village black-smith!