Having been in book publishing going on 40 years, the choice to use 'distressed type' to simulate the look of period documents is up to the editorial team. The company I work for recently produced a book that some did not like for other reasons but it sold well. In the end, not everyone can be pleased but my reading of the book trade press shows that, for various reasons, this has always been the case. I do recognize that due to various specific reasons mentioned here, that looking at such type has been a problem for some and it is appropriate to bring this up.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Secret Horsepower Race by Calum Douglas (and piston engine discussion)

- Thread starter edwest4

- Start date

Dagger

ACCESS: Secret

- Joined

- 24 December 2019

- Messages

- 297

- Reaction score

- 490

Not spoiled, I said slightly spoiled. A book is to be read, so even if only part of the readers has a problem with the readability of the font then that is something to take seriously.

.............

I must respectfully disagree with your point that a great book can be spoiled if it is printed in any given font that you personally dislike. I would suggest that a great book remains a great book regardless of the fonts used in its presentation.

Imagine you had slaved over a book for years and all the critics had to say about it was how much they disliked the fonts used. Would you be overjoyed to see that someone had ignored absolutely everything you had written and chosen instead to complain about the font it was printed in? Or would you, instead, feel as though you were being trolled by such comments.

.............

If I had written something and several people would indicate to dislike the font due to unpleasant readability then I would thank them for pointing that out and take it into account in my future work.

I would certainly not call them trolls.

- Joined

- 11 June 2014

- Messages

- 1,333

- Reaction score

- 1,780

Not spoiled, I said slightly spoiled. A book is to be read, so even if only part of the readers has a problem with the readability of the font then that is something to take seriously.

.............

I must respectfully disagree with your point that a great book can be spoiled if it is printed in any given font that you personally dislike. I would suggest that a great book remains a great book regardless of the fonts used in its presentation.

Imagine you had slaved over a book for years and all the critics had to say about it was how much they disliked the fonts used. Would you be overjoyed to see that someone had ignored absolutely everything you had written and chosen instead to complain about the font it was printed in? Or would you, instead, feel as though you were being trolled by such comments.

.............

If I had written something and several people would indicate to dislike the font due to unpleasant readability then I would thank them for pointing that out and take it into account in my future work.

I would certainly not call them trolls.

We may have to agree to disagree.

- Joined

- 11 June 2014

- Messages

- 1,333

- Reaction score

- 1,780

Having been in book publishing going on 40 years, the choice to use 'distressed type' to simulate the look of period documents is up to the editorial team. The company I work for recently produced a book that some did not like for other reasons but it sold well. In the end, not everyone can be pleased but my reading of the book trade press shows that, for various reasons, this has always been the case. I do recognize that due to various specific reasons mentioned here, that looking at such type has been a problem for some and it is appropriate to bring this up.

The above comments made concerning legibility have been noted and will be given due consideration when future editions are commissioned. As I said earlier though, the book we have looks the way it looks.

Were there any areas of the book where it felt as though more detail was needed, or where particular developments were skimmed over too quickly? For example, Calum has VAST quantities of material on WW2 engine projects which only reached the drawing board or prototype stage. For reasons of space we were forced to focus on the development of engines which actually made a difference militarily to the exclusion of those that did not.

I vaguely recall too that certain drawings of previously unknown British secret project piston engine fighters even had to be (reluctantly) cut because we didn't have room for them...

Last edited:

- Joined

- 27 December 2005

- Messages

- 16,446

- Reaction score

- 19,122

That's fine @newsdeskdan, and I'm sure this was the spirit in which the feedback was intended by all here.

Having been in book publishing going on 40 years, the choice to use 'distressed type' to simulate the look of period documents is up to the editorial team. The company I work for recently produced a book that some did not like for other reasons but it sold well. In the end, not everyone can be pleased but my reading of the book trade press shows that, for various reasons, this has always been the case. I do recognize that due to various specific reasons mentioned here, that looking at such type has been a problem for some and it is appropriate to bring this up.

The above comments made concerning legibility have been noted and will be given due consideration when future editions are commissioned. As I said earlier though, the book we have looks the way it looks.

Were there any areas of the book where it felt as though more detail was needed, or where particular developments were skimmed over too quickly? For example, Calum has VAST quantities of material on WW2 engine projects which only reached the drawing board or prototype stage. For reasons of space we were forced to focus on the development of engines which actually made a difference militarily to the exclusion of those that did not.

I vaguely recall too that certain drawings of previously unknown British secret project piston engine fighters even had to be (reluctantly) cut because we didn't have room for them...

Regarding unknown British secret project piston engine fighters, perhaps Tony Buttler may be interested if Mortons is not.

- Joined

- 18 June 2009

- Messages

- 1,290

- Reaction score

- 2,102

On page 29 in the second sentence of the upper right hand column:

"The calculation must be run for each pair of six crankshaft pins in steps of 100 of crankshaft angle---eventually producing the figure (below)."

Should "degrees" follow the 100?

"The calculation must be run for each pair of six crankshaft pins in steps of 100 of crankshaft angle---eventually producing the figure (below)."

Should "degrees" follow the 100?

- Joined

- 11 June 2014

- Messages

- 1,333

- Reaction score

- 1,780

On page 29 in the second sentence of the upper right hand column:

"The calculation must be run for each pair of six crankshaft pins in steps of 100 of crankshaft angle---eventually producing the figure (below)."

Should "degrees" follow the 100?

It's 10 degrees. The second '0' was meant to be a degrees symbol. This has been corrected for the second print run.

- Joined

- 25 June 2014

- Messages

- 1,564

- Reaction score

- 1,453

Were there any areas of the book where it felt as though more detail was needed, or where particular developments were skimmed over too quickly?

Of course! Volume II is eagerly awaited!!!

Seriously, this is an instant reference work and publishing all this material is a wonderful thing. However, I have doubts about the viability of such a second "arcana" volume, it becomes the sort of thing that academic publishers do not pay the author or peer reviewers for, charge $120+ for, and sell only to libraries and rich institutions. Volume I at an affordable price is better for the likes of me than twice the paywalled information.

Last edited:

- Joined

- 19 July 2016

- Messages

- 3,727

- Reaction score

- 2,690

I would just like to say that, having glanced through the book again today and seen the Me-409 pieces, I believe this to be one of the best value, if not THE best value military tech books ever and we will have to go a lot of country miles to even come close. Very grateful that this man went through so much to bring it to us and the price is a bleedin' steal.......

I would just like to say that, having glanced through the book again today and seen the Me-409 pieces, I believe this to be one of the best value, if not THE best value military tech books ever and we will have to go a lot of country miles to even come close. Very grateful that this man went through so much to bring it to us and the price is a bleedin' steal.......

That was pure luck, I was in the DB corporate archives and happened to look in a folder called "Ringkuhler" - most of which was indeed fairly uninteresting images of front mounted ring-pattern radiators. However, I think because the 409 propnose has a "ring air entry" to the first stage supercharger, which looks a bit "Ringkühlerey" an achivist there way back in the day (probably prior to 1980s) just stuffed the "Me 409" photos in with it. I only had 2 full days there, and would have needed another 2 weeks to have surveyed every folder. It is suprisingly complete, although I think many later developments in the final chaotic year or so were not well catalogued or preserved, I "suspect" that may well be because by that time the design staff at Untertürkheim were all working remotely in various small repurposed factories at the outskirts of Stuttgart, and probably their drawings never made it back to the central plant. Hence why I only found the DB 603 N variable valve timing drawings with Dr Kollmann's son, and not at the DB archives.

Cannonfodder43

ACCESS: Confidential

- Joined

- 8 December 2019

- Messages

- 107

- Reaction score

- 263

Received my copy two days ago. An impressive piece of work that I am sure to enjoy in the next few days. Arrived stuffed in a bag for rain protection and puzzled my family since they had no idea what it was.

Attachments

Last edited:

Very happy it arrived, and I hope your cat also likes it. Mine very much enjoyed sitting on the draft copies when I was proof reading. Please delete the 1st image though as it has your home address visible!Received my copy two days ago. An impressive piece of work that I am sure to enjoy in the next few days. Arrived stuffed in a bag for rain protection and puzzled my family since they had no idea what it was.

- Joined

- 25 June 2014

- Messages

- 1,564

- Reaction score

- 1,453

Pleased to stumble on Max Millar's wonderful cutaway of the Merlin 61, if labelled in German. Similar cutaways of several other engines, mostly British, which preoccupy this book are republished in Bill Gunston's Classic World War II Aircraft Cutaways (Osprey 1995, 1997, Bounty 2011). The accompanying text delights in pointing out the draughtsman's slips. The supercharged DB 601 and BMW 801 get the treatment, but sadly not the Jumo 211 or, in the UK, the two-stage supercharged Merlin (hence my pleasure in finding it now). Oddly, the prewar supercharged Napier Dagger does get a look-in.

The anecdote that Millar was nearly censored for putting in too much sensitive information reminds me of the old story about the Lockeed F-104 Starfighter. The Flight artist of the day (Mike Badrocke?) looked at the rivet lines and similar in photos, to reverse-engineer its highly secret internals for the journal's traditional cutaway. US Intelligence promptly pounced on him to find out who his mole was, thus revealing to a somewhat astonished artist that his deductions had been pretty much spot-on.

Presumably the British details were allowed out in part because of the morale boost they gave, and in part in recognition of the fact that the Germans would capture examples in short order if they hadn't already. There are no US engines in Guston's book. One gets the impression that the British public would have known more about the enemy's than their own allies', while the Germans knew more about the US engines than the American public did. Perhaps the lack of journalistic criticism this engendered was one reason the Americans could let Wright Field become such a bad joke.

One wonders what would have become of the Merlin, and of the course of the war, if Hives had not stood up against following American and German practice and the UK had dispatched half of Rolls-Royce's engineers to the battle front. Maybe it should go down in the history books not as WWII but as Hives' War.

The anecdote that Millar was nearly censored for putting in too much sensitive information reminds me of the old story about the Lockeed F-104 Starfighter. The Flight artist of the day (Mike Badrocke?) looked at the rivet lines and similar in photos, to reverse-engineer its highly secret internals for the journal's traditional cutaway. US Intelligence promptly pounced on him to find out who his mole was, thus revealing to a somewhat astonished artist that his deductions had been pretty much spot-on.

Presumably the British details were allowed out in part because of the morale boost they gave, and in part in recognition of the fact that the Germans would capture examples in short order if they hadn't already. There are no US engines in Guston's book. One gets the impression that the British public would have known more about the enemy's than their own allies', while the Germans knew more about the US engines than the American public did. Perhaps the lack of journalistic criticism this engendered was one reason the Americans could let Wright Field become such a bad joke.

One wonders what would have become of the Merlin, and of the course of the war, if Hives had not stood up against following American and German practice and the UK had dispatched half of Rolls-Royce's engineers to the battle front. Maybe it should go down in the history books not as WWII but as Hives' War.

Last edited:

Pasoleati

I really should change my personal text

- Joined

- 29 June 2012

- Messages

- 496

- Reaction score

- 166

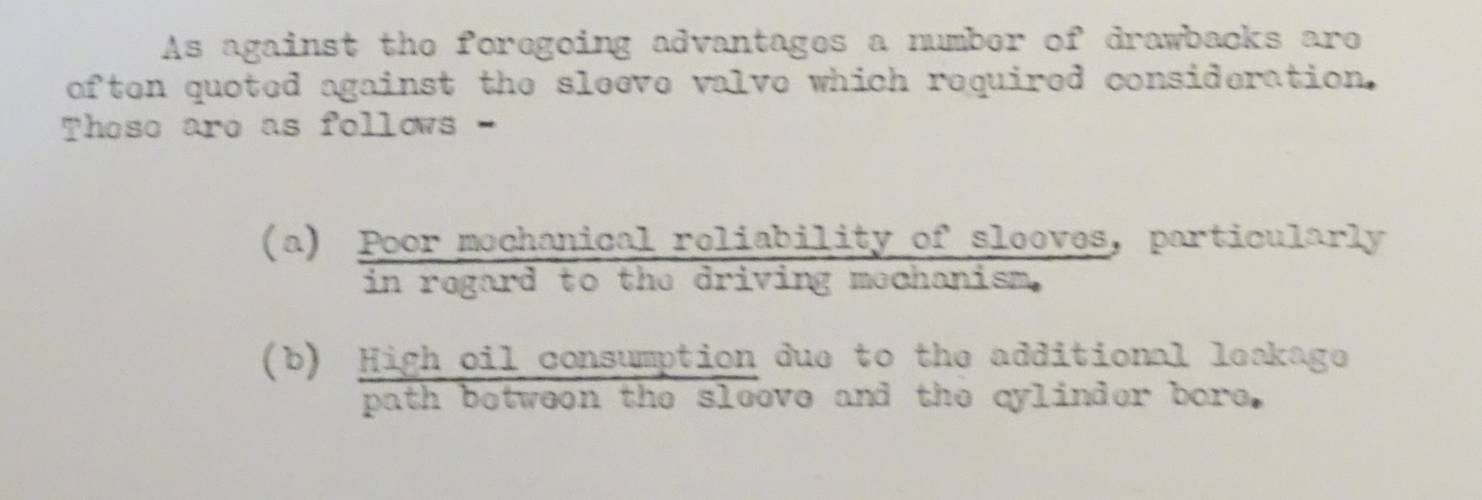

I have to disagree with Calum on pages 25-26. He calls Fedden's decision to adopt sleeve-valves a "serious misjudgement". I disagree because I think sleeve-valves are so vastly superior to poppet valves. Just look at e.g. the maximum allowed C. H. T. of radials with both systems. Massive advantage to the sleeve-valves!

I suggest you finish the book before announcing that. There is absoutely no performance evidence to suggest they were in any useful way superior, but just absorbed 5 years development work to end up with someing no better performance wise, and in fact due to liner deformation, a lower maximum boost limit and also dramatically higher oil consumption. These are not subjective points. They are wonderful, fascinating tributes to what can be achieved, with many packaging advantages, but were the wrong technical path. They are also difficult to turbocharge as the increased backpressure tends to push oil away from the exhaust port/sleeve interface and generates accelerated wear.I have to disagree with Calum on pages 25-26. He calls Fedden's decision to adopt sleeve-valves a "serious misjudgement". I disagree because I think sleeve-valves are so vastly superior to poppet valves. Just look at e.g. the maximum allowed C. H. T. of radials with both systems. Massive advantage to the sleeve-valves!

Looking at engine performance specs (as opposed to what the temperature this, or that was) there is no evidence that any wartime sleeve valve engine out-performed the boost levels achieved by the R2800, which doesnt even have a 4 valve head.

Please just speak plainly instead of using acroynms, "Cylinder Head Temperature". There are also no data on that on pages 25-26, so you might want to provide references so everyone knows what you`re trying to say.

Everyone has their own favourite engines, which often have little to do with best/lightest/most powerful/most reliable/most prudent - but sadly, I suggest its important to distinguish from a dispassionate analysis of what was the best choice in the lead up to war - and what you might enjoy most. The book is not a critisism of anyones enjoyment of any engine, its a critical analysis of what the best technological choices back then, were.

Last edited:

- Joined

- 25 June 2014

- Messages

- 1,564

- Reaction score

- 1,453

I have to agree with Calum that judging an expert opinion based on only 5% of its presentation is somewhat premature. I also feel that such rash disparagement is discourteous and that even the Internet should exhibit some sense of good manners.

But then I am in a bad mood because I just saw a BF109G kit going for a song and didn't buy it because it has the wrong variant of the DB 601 for the Spitfire they put one in - but on checking back home, they put a 109G prop on it anyway. Rats!

Mind you, I would suggest that the disaster is only apparent with hindsight. The sheer bloody-mindedness of the sleeve valve, in just not quite making up its mind for so long, could not have been predicted in advance; it was more of a gamble that didn't pay off, with disastrous results.

I am all agog to see whether the DB disc valve took the stage again in 1944-5.

But then I am in a bad mood because I just saw a BF109G kit going for a song and didn't buy it because it has the wrong variant of the DB 601 for the Spitfire they put one in - but on checking back home, they put a 109G prop on it anyway. Rats!

Mind you, I would suggest that the disaster is only apparent with hindsight. The sheer bloody-mindedness of the sleeve valve, in just not quite making up its mind for so long, could not have been predicted in advance; it was more of a gamble that didn't pay off, with disastrous results.

I am all agog to see whether the DB disc valve took the stage again in 1944-5.

Last edited:

Pleased to stumble on Max Millar's wonderful cutaway of the Merlin 61, if labelled in German. Similar cutaways of several other engines, mostly British, which preoccupy this book are republished in Bill Gunston's Classic World War II Aircraft Cutaways (Osprey 1995, 1997, Bounty 2011). The accompanying text delights in pointing out the draughtsman's slips. The supercharged DB 601 and BMW 801 get the treatment, but sadly not the Jumo 211 or, in the UK, the two-stage supercharged Merlin (hence my pleasure in finding it now). Oddly, the prewar supercharged Napier Dagger does get a look-in.

The anecdote that Millar was nearly censored for putting in too much sensitive information reminds me of the old story about the Lockeed F-104 Starfighter. The Flight artist of the day (Mike Badrocke?) looked at the rivet lines and similar in photos, to reverse-engineer its highly secret internals for the journal's traditional cutaway. US Intelligence promptly pounced on him to find out who his mole was, thus revealing to a somewhat astonished artist that his deductions had been pretty much spot-on.

Presumably the British details were allowed out in part because of the morale boost they gave, and in part in recognition of the fact that the Germans would capture examples in short order if they hadn't already. There are no US engines in Guston's book. One gets the impression that the British public would have known more about the enemy's than their own allies', while the Germans knew more about the US engines than the American public did. Perhaps the lack of journalistic criticism this engendered was one reason the Americans could let Wright Field become such a bad joke.

One wonders what would have become of the Merlin, and of the course of the war, if Hives had not stood up against following American and German practice and the UK had dispatched half of Rolls-Royce's engineers to the battle front. Maybe it should go down in the history books not as WWII but as Hives' War.

In the US, the Office of War Information was established to make sure that nothing of value was provided to the enemy. Even photos sent home by soldiers carried a "Passed by Censor" stamp. I am continuing my research into the goings-on at Wright Field during and shortly after the war, including relatively new, to me, information about their work with German ejection seats.

- Joined

- 19 July 2016

- Messages

- 3,727

- Reaction score

- 2,690

That would be interesting to see.

Pasoleati

I really should change my personal text

- Joined

- 29 June 2012

- Messages

- 496

- Reaction score

- 166

A B-series R-2800 was limited to 232 deg C with a lean mixture. A Hercules XVI's comparable figure is 300 deg C.

As for oil consumption, figures given in R-2800 and Centaurus manuals do not suggest significant differences in oil consumption.

As for oil consumption, figures given in R-2800 and Centaurus manuals do not suggest significant differences in oil consumption.

A B-series R-2800 was limited to 232 deg C with a lean mixture. A Hercules XVI's comparable figure is 300 deg C.

As for oil consumption, figures given in R-2800 and Centaurus manuals do not suggest significant differences in oil consumption.

The propellor doesnt care what the head temperature limits are, which are in any case primarily about material limits.

Its actually remarkably difficult to compare technologies by looking at totally different engines, even if you average

out quite a few (you were a while back trying to persuade me that direct injection wasnt more economical

than a carburettor using this tactic). This is even more problematic with oil consumption figures, which

are often recorded in such different methods its not at all easy to make a direct comparison, and even then

the variations in totally different engines often obscure the individual factors.

So we can pick any pair of engines we like to "prove" any point. For example a Merlin at min consumption

is nearly five times less than an Sabre on a "per/bhp/hp" basis, and almost half a centaurus. A BMW 801

also has lower min consumption than any of the sleeve valve engines and at max consumption

a bit higher. However the R2800 which has the worst specific oil consumption of the entire war as far as I can tellhas slighly

higher consumption than a Sabre, and much higher than a Centaurus. The variation in min/max spreads vary

wildly, some Jumo211`s have only 5% difference between min and max consumption, but a BMW801 has almost

three times greater consumption at max oil consumption!

The breather systems used in the specific engines for example, have a collosal impact on oil consumption. This is

obviously totally independant of the valve system used.

The best bet, is to read the reports of each manufacturer, preferebly one who has desiged, built and

tested both types themselves and see what they thought.

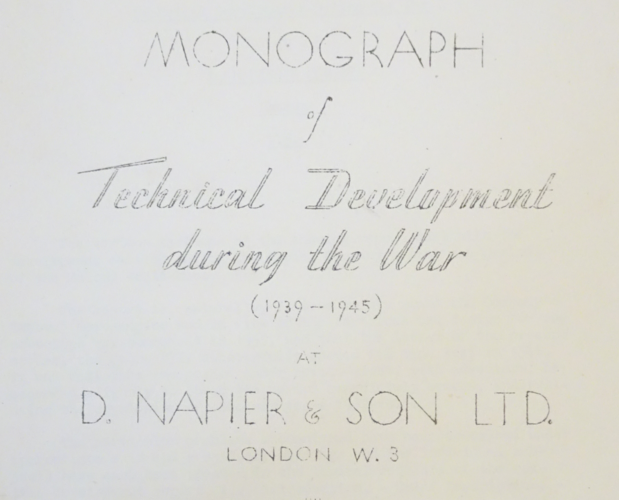

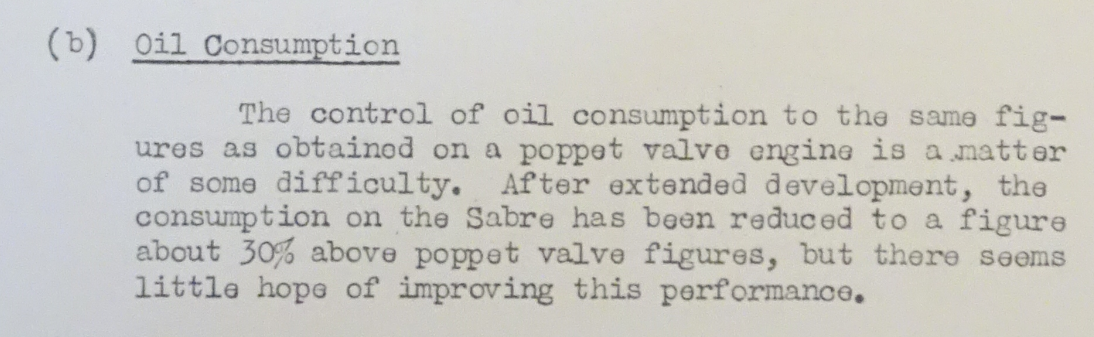

This is what Napier thought (having a lot of experience with both types of value systems)

Nobody designs new engines today with carburettors OR sleeve valves, there is an extremely good reason for that.

Last edited:

- Joined

- 18 June 2009

- Messages

- 1,290

- Reaction score

- 2,102

So sleeve valve engines can develop more power in a test bench environment. More importantly, how would they fare in a working environment of field maintenance and combat damage.

The document already says they are harder to maintain and would require more spare parts to make and keep supplied. I cannot imagine them surviving the slightest damage to a cylinder penetration that would take out the barrel, sleeve, piston, and probably the sleeve drive mechanism which would then drop pieces into the crankcase to do more damage. I worked for a B-24 pilot who told me about watching radials with barrels blown off still keep on running. I don't think a sleeve valve engine with many more complex pieces would tolerate that kind of damage and would be much harder to fix in a field environment. Oil starvation would probably would cause much faster and more severe damage to a sleeve valve engine than a poppet valve engine.

The document already says they are harder to maintain and would require more spare parts to make and keep supplied. I cannot imagine them surviving the slightest damage to a cylinder penetration that would take out the barrel, sleeve, piston, and probably the sleeve drive mechanism which would then drop pieces into the crankcase to do more damage. I worked for a B-24 pilot who told me about watching radials with barrels blown off still keep on running. I don't think a sleeve valve engine with many more complex pieces would tolerate that kind of damage and would be much harder to fix in a field environment. Oil starvation would probably would cause much faster and more severe damage to a sleeve valve engine than a poppet valve engine.

- Joined

- 25 June 2014

- Messages

- 1,564

- Reaction score

- 1,453

So sleeve valve engines can develop more power in a test bench environment. More importantly, how would they fare in a working environment of field maintenance and combat damage.

The document already says they are harder to maintain and would require more spare parts to make and keep supplied. I cannot imagine them surviving the slightest damage to a cylinder penetration ... I worked for a B-24 pilot who told me about watching radials with barrels blown off still keep on running.

At risk of pre-empting Calum, it appears fair to say that the sleeve valve will only develop more power up to a point. When combat boost is engaged, the poppet valve seems to tolerate the overload for a longer period.

As far as failure goes, all these combat engines are so highly stressed that even minor damage will cause the piston and con-rod to self-destruct; whether the valve system is still functioning becomes irrelevant. If the whole barrel blows off it takes the valve mechanism with it, so again irrelevant to the poppet-vs-sleeve issue.

- Joined

- 25 June 2014

- Messages

- 1,564

- Reaction score

- 1,453

There is a saying among certain modelling fraternities; "You can never have too many Spitfires". Now, I know it goes against the ethos of the cover artwork  , but for me, one of the highlights of Calum's book is the performance graph for CJ-ZY, the Spitfire Vb fitted with a DB 605 by the Germans to test its radiators.

, but for me, one of the highlights of Calum's book is the performance graph for CJ-ZY, the Spitfire Vb fitted with a DB 605 by the Germans to test its radiators.

As an aside, it supports my thesis that it is better to modify one comparison aircraft than to modify a Spit off every blasted manufacturer's production line, just to prove a point.

Back down at 1:72 scale, I have found a three-bladed prop in my spares box which is likely no less accurate than the average Bf 109G kit, I just need a Bf 110G kit now, for the engine installation and spinner.

For those who share my enthusiasm, here is an account I scraped off the Internet. Much or all of seems to be quite widely copied, if anybody knows the original source I'd be glad of a tip-off:

As an aside, it supports my thesis that it is better to modify one comparison aircraft than to modify a Spit off every blasted manufacturer's production line, just to prove a point.

Back down at 1:72 scale, I have found a three-bladed prop in my spares box which is likely no less accurate than the average Bf 109G kit, I just need a Bf 110G kit now, for the engine installation and spinner.

For those who share my enthusiasm, here is an account I scraped off the Internet. Much or all of seems to be quite widely copied, if anybody knows the original source I'd be glad of a tip-off:

Spitfire Vb serial EN830 / NX-X fell into German hands late in 1942. It crash landed on November 18th 1942 while being flown by P/O (Sous Lt.) Bernard Scheidhauer of the Free French Air Force, attached to 131 "County of Kent" Sqn. RAF. He and his No.1, P/O Henri de Bordas, had been on a "rhubarb" to Normandy during the afternoon. EN830 was hit by light flak and made a forced landing in a turnip field at Dielament Manor, Trinity, Jersey.

Sous Lt Scheidhauer was taken prisoner by the Germans and, like his aircraft, was transported to Germany. On March 24th, 1944 he and 80 other RAF officers escaped from Stalag Luft 3. He was captured along with his escape partner Sq. Ldr. Roger Bushell in Saarbrucken. The were both shot for their part in the "Great Escape" on 28th March 1944. His aircraft was captured virtually intact, and in good enough condition to be flown in November 1943, with black crosses in place of RAF roundels, to Rechlin for testing.

In early spring of 1941, another Spitfire had been tested here. A suggestion that it be tested with a Daimler-Benz engine to enable a more direct comparison with the Luftwaffe's Messerschmitt Bf.109 led to it being flown to the Daimler-Benz facility at Backnang, near Stuttgart, on April 24, 1941. There it was to receive a DB 601 engine. This work proved too difficult and the project was abandoned. That aircraft returned to Rechlin on September 9, 1942.

The acquisition of a second Spitfire, EN830, revived the idea. It was sent to Echterdingen, south of Stuttgart, where Daimler-Benz operated a flight testing division. Flugkapitän Willy Ellenreider and his staff were responsible for testing to improve performance of other current aircraft, and a number of types served as flying test-beds. Among them were Ju.52s with a DB 605 engine in the centre position; He.111s, Hs.130s, Bf.109s and 110s, a Ju.87 and an Fi.167.

Spitfire EN830 was repainted to German standards, dark green above and pale blue below, with bright yellow tail control surfaces and large, black crosses. Radio code letters CJ+ZY were painted on each side, below and, unusually, above the wings; and the British serial transferred to the fin above the swastika.

The Spitfire reached Echterdingen minus guns and ammunition, with the gun ports closed. The radio had been replaced with ballast, but it still had its original Merlin 45 engine. Several flights were made by Daimler-Benz pilots before conversion was attempted. A decision was made to replace the intruments and the entire electrical system with standard German equipment, because the Luftwaffe used a 24 volt system, whilst the RAF used a 12 volt standard.

After the Merlin engine was removed, it was discovered that the Spitfire's front fuselage cross-section was very close to that of the standard Bf.110G's engine cowling. A new engine support was designed, and a standard DB 605A-1 engine (Wk-Nr 00701990) was mounted to the fire wall. The work was completed at the Sindelfingen Daimler-Benz factory, near Echterdingen.

A 3.0 m. diameter Bf.109G propellor was added, together with the carburettor scoop from a Bf.109G. This made the modified Spitfire's all-up weight, without armament, 6,020 lb. (2730 kg). The armament weight was an estimated additional 661 lb. (300 kg.). Its weight with armament, before the engine modification, had been 6,680 lb. (3030 kg.).

After a couple of weeks, and with a new yellow-painted nose, the Spitfire returne to Echterdingen. Ellenreider was the first to try the aircraft. He was stunned that the aircraft had much better visibility and handling on the ground than the Bf.109. It took off before he realised it and had an impressive climb rate, around 70 ft. (21 m.) per second. Much of the Spitfire's better handling could be attributed to its lower wing loading.

The Spitfire's wing area was about 54 sq. ft. (5m²) greater than that of the Bf.109. The Messerschmitt was faster at low altitude, but at 11,000 ft. (3350 m) the speeds evened out. The DB 605A engine gave better performance, according to the test group, than the Merlin, which was rated 150 hp below the German engine. It gave the Spitfire a ceiling of 41,666 ft. (12700 m.), about 3,280 ft. (1000 m.) more than a Bf.109G with the same engine and 5,166 ft. (1475 m.) more than that of a Spitfire Mk.V.

After a brief period at Rechlin confirming the performance data, the modified Spitfire returned to Echterdingen to serve officially as a test bed. It was popular with the pilots in and out of working hours. Its career ended on 14th August, 1944, when a formation of US bombers attacked Echterdingen, wrecking two Ju.52s, three Bf.109Gs, a Bf.109H V1, an FW.190 V16, an Me.410 and the Spitfire. The remains of the hybrid Spitfire were scrapped at the Klemm factory at Böblingen.

- Joined

- 19 July 2016

- Messages

- 3,727

- Reaction score

- 2,690

I wonder if the improvement was down to fuel injection over carbs?

So sleeve valve engines can develop more power in a test bench environment. More importantly, how would they fare in a working environment of field maintenance and combat damage.

The document already says they are harder to maintain and would require more spare parts to make and keep supplied. I cannot imagine them surviving the slightest damage to a cylinder penetration that would take out the barrel, sleeve, piston, and probably the sleeve drive mechanism which would then drop pieces into the crankcase to do more damage. I worked for a B-24 pilot who told me about watching radials with barrels blown off still keep on running. I don't think a sleeve valve engine with many more complex pieces would tolerate that kind of damage and would be much harder to fix in a field environment. Oil starvation would probably would cause much faster and more severe damage to a sleeve valve engine than a poppet valve engine.

Sadly I have no data on which to form a view of "serious mechanical damage survivability" of the various types.

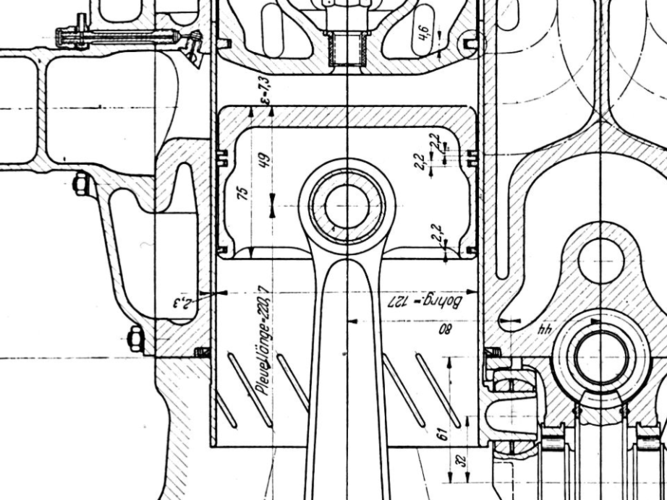

The power issue is complicated, there are grounds for saying that the sleeve valve can allow more air to be stuffed into the cylinder at a given pressure than even a 4-valve head, however (e.g. Sabre Exhaust port max opening area = 23cm^2, and BMW 801E = 20cm^2), the pressure at which that carries on being possible to combust seems to be lower than that of a GOOD 4-valve head. In other words its more difficult with a sleeve system to accept very high cylinder pressures after you`ve ignited what you`ve managed to stuff into the cylinder.

There are several reasons for this, but the main one seems to have been that at very high boost levels it becomes very hard to get the moving sleeve to stay round (by which I mean after these dense charges are ignited). This might sound rather silly, because the sleeve is of course a cylinder, and ought therfore to expand in symetry. However, the sleeve is NOT actually symetrical because it has cut-outs for the ports, these are of course covered up at peak combustion pressure inside the junk head. But they still mean the sleeve as a whole isnt actually quite expanding as a perfect sleeve ought to.

Just doing some quick sums, if one uses the peak cylinder pressure of a V-1650 with 67" Hg manifold pressure (33 PSI or 2.27 Bar), you get 1500 PSI

peak cylinder pressure.

This is enough to expand a sleeve about 3.2 thousands of an inch (momentarily), in actuality a horribly simple sum like the one I`ve just done in EXCEL

isnt realistic, because the peak pressure is only acting for a tiny fraction of a second over a very small area of the sleeve near piston TDC. However

that number is a major proportion of the radial clearance of the sleeve (when its hot) so I think conceptually you can see what sort of issues will arise at very high

boost values. (again, note this is independant of the "breathing capacity" of the sleeve in a flow-bench test, we`re talking about what happens once

you ignite it). As you can see the sleeve is really rather thin !

I have not analysed it, but another thing I suspect limits maximum cylinder pressures would be piston thrust-face side loads onto the bores. This is obviously an asymetric loading which will seek to deform the bore and hence increase friction and potentially jam it eventually. I suspect that a combination of the sleeve expansion under pressure and piston side-thrust loads are the main drivers limiting boost. You can of course just make the sleeves much thicker, but then the weight of the

engine goes way up, and the stress on the valve drive gear rockets. So its a very difficult compromise.

If you look at the Centaurus overhaul manual, it says "Examine the sleeves for bulging, especially in the areas immidiately below the ports".

On the other hand the Sabre layout lends itself to high crankshaft speeds because its inherently balanced and has a short stroke. so probably its suited to having its rpm increased, and not at such high boosts as very good poppet valve engines like the Merlin or Packard variants etc.

I would like to press-home the point that this is a critical analysis of what ought to have been done in the war with hindsight, and in fact the incredible challenges these engineers faced with such endevours makes restoring engines like the Sabre and Centaurus of great importance today. I very strongly support the restoration to flight of Tempest and Typhoons such equipped. The hercules was outstandingly reliable as a civil engine, and I think providing the limits are treated respectfully, there is no good reason not to restore and fly a sleeve valve today.

Last edited:

- Joined

- 25 June 2014

- Messages

- 1,564

- Reaction score

- 1,453

Hooray for lockdown! This book is a surefire cure for lockdown loneliness. I have now worked my way right through it, phew! Superlative! There, that's my last superlative used up.

Just some ignorant thoughts on alternatives to the poppet valve, which I hope the wise might care to illuminate:

I read somewhere that whether a sleeve valve sits inside or outside the cylinder is not especially significant. However it occurs to me that once you have a wet liner the obvious thought is to forget the "top hat" junction and combine the two as a single "liner sleeve". Why ever not?

The rotary disc valve was criticised because it left a dead space between the rotor and the cylinder, where combustion would be unhappy. But Ricardo had already investigated a similar small cavity in order to create a stable stratified charge arrangement. Also/alternatively, by making the disc more of a (subtly different) top hat, the gap can be made less dependent on structural consideration. Did Jumo miss another opportunity there?

Now, wherever did I leave my Zimmer frame?...

Just some ignorant thoughts on alternatives to the poppet valve, which I hope the wise might care to illuminate:

I read somewhere that whether a sleeve valve sits inside or outside the cylinder is not especially significant. However it occurs to me that once you have a wet liner the obvious thought is to forget the "top hat" junction and combine the two as a single "liner sleeve". Why ever not?

The rotary disc valve was criticised because it left a dead space between the rotor and the cylinder, where combustion would be unhappy. But Ricardo had already investigated a similar small cavity in order to create a stable stratified charge arrangement. Also/alternatively, by making the disc more of a (subtly different) top hat, the gap can be made less dependent on structural consideration. Did Jumo miss another opportunity there?

Now, wherever did I leave my Zimmer frame?...

Hooray for lockdown! This book is a surefire cure for lockdown loneliness. I have now worked my way right through it, phew! Superlative! There, that's my last superlative used up.

Just some ignorant thoughts on alternatives to the poppet valve, which I hope the wise might care to illuminate:

I read somewhere that whether a sleeve valve sits inside or outside the cylinder is not especially significant. However it occurs to me that once you have a wet liner the obvious thought is to forget the "top hat" junction and combine the two as a single "liner sleeve". Why ever not?

The rotary disc valve was criticised because it left a dead space between the rotor and the cylinder, where combustion would be unhappy. But Ricardo had already investigated a similar small cavity in order to create a stable stratified charge arrangement. Also/alternatively, by making the disc more of a (subtly different) top hat, the gap can be made less dependent on structural consideration. Did Jumo miss another opportunity there?

Now, wherever did I leave my Zimmer frame?...

Glad you liked it, thank you for your kind remarks.

Regarding the "liner-sleeve" - I`m afraid I`m not convinced I`ve grasped what you`re asking correctly, if you can elaborate on it I`ll try to give a view on it.

Regarding the disc-valve question, I do see what you`re getting at, I would only really say that you have four cavities with a disc head, and so repurposing one as a little prechamber etc, doesnt really solve the disagreeable geometry the other 3 "stumps" leave you with. I feel the disc valve is just too problematic to get to work properly with any reliablity. However... it did make for a very interesting torpedo engine... (the KM8) but thats another story !

A really fun overview of all the crazy valve designs ever used can be found here:

Rotary-Valve Internal Combustion Engines.

Douglas Self, rotary valve engines, Minerva, Aspin valve, Cross valve, Froede valve, Wankel valve, Mellors Rotary Valve

www.douglas-self.com

- Joined

- 25 June 2014

- Messages

- 1,564

- Reaction score

- 1,453

I suppose one should call it a semi-wet liner. The idea is to have a single moving sleeve which is both the valve and the liner. The outer side of the sleeve would mostly be in contact with the coolant, except for:Regarding the "liner-sleeve" - I`m afraid I`m not convinced I`ve grasped what you`re asking correctly, if you can elaborate on it I`ll try to give a view on it.

- inlet and exhaust ducts

- fixed blanking plates which seal the valve holes when they move away from the ports

- support structures

To reduce cross-contamination between fuel and coolant there would be a "scavenge" cavity in all sliding seals, from where any leakage would be pumped away and separated.

I can foresee distortion problems at high power levels, so whether the main block might have more of a perforated wall than an open cavity might be debatable. The principle of moving past the coolant could be used to avoid hot and cold spots.

Ha! I had no idea I was among so many like-minded nutters. No sleeves, but I see my daughter's French horn gets a mention. Bloody awful things, they need a length of cord to actuate, have a large diameter which requires scrupulous maintenance to keep smooth, and tend to gum up after a while. Give me the sliding trumpet valve any day.A really fun overview of all the crazy valve designs ever used can be found here:

Rotary-Valve Internal Combustion Engines.

Douglas Self, rotary valve engines, Minerva, Aspin valve, Cross valve, Froede valve, Wankel valve, Mellors Rotary Valvewww.douglas-self.com

Last edited:

Ah ok, I dont think it would be possible to seal the water area, is my opinion, and if you move the water far enough away that outs out of the zone of movement of the port-cuts, its so far away from the main area where combustion is occuring at the top where the temps are highest, that its not doing any good...I suppose one should call it a semi-wet liner. The idea is to have a single moving sleeve which is both the valve and the liner. The outer side of the sleeve would mostly be in contact with the coolant, except for:Regarding the "liner-sleeve" - I`m afraid I`m not convinced I`ve grasped what you`re asking correctly, if you can elaborate on it I`ll try to give a view on it.

- inlet and exhaust ducts

- fixed blanking plates which seal the valve holes when they move away from the ports

- support structures

To reduce cross-contamination between fuel and coolant there would be a "scavenge" cavity in all sliding seals, from where any leakage would be pumped away and separated.

I can foresee distortion problems at high power levels, so whether the main block might have more of a perforated wall than an open cavity might be debatable. The principle of moving past the coolant could be used to avoid hot and cold spots.

Ha! I had no idea I was among so many like-minded nutters. No sleeves, but I see my daughter's French horn gets a mention. Bloody awful things, they need a length of cord to actuate, have a large diameter which requires scrupulous maintenance to keep smooth, and tend to gum up after a while. Give me the sliding trumpet valve any day.A really fun overview of all the crazy valve designs ever used can be found here:

Rotary-Valve Internal Combustion Engines.

Douglas Self, rotary valve engines, Minerva, Aspin valve, Cross valve, Froede valve, Wankel valve, Mellors Rotary Valvewww.douglas-self.com

- Joined

- 25 June 2014

- Messages

- 1,564

- Reaction score

- 1,453

Possibly not, but it'd be fun to spend ten years trying.I dont think it would be possible to seal the water area

Calum, how does one gain access to those archives? Do you have to have university credentials? Government approval/endorsement, pay a fee?I would just like to say that, having glanced through the book again today and seen the Me-409 pieces, I believe this to be one of the best value, if not THE best value military tech books ever and we will have to go a lot of country miles to even come close. Very grateful that this man went through so much to bring it to us and the price is a bleedin' steal.......

That was pure luck, I was in the DB corporate archives and happened to look in a folder called "Ringkuhler" - most of which was indeed fairly uninteresting images of front mounted ring-pattern radiators. However, I think because the 409 propnose has a "ring air entry" to the first stage supercharger, which looks a bit "Ringkühlerey" an achivist there way back in the day (probably prior to 1980s) just stuffed the "Me 409" photos in with it. I only had 2 full days there, and would have needed another 2 weeks to have surveyed every folder. It is suprisingly complete, although I think many later developments in the final chaotic year or so were not well catalogued or preserved, I "suspect" that may well be because by that time the design staff at Untertürkheim were all working remotely in various small repurposed factories at the outskirts of Stuttgart, and probably their drawings never made it back to the central plant. Hence why I only found the DB 603 N variable valve timing drawings with Dr Kollmann's son, and not at the DB archives.

I'm looking forward to your book, but amazon.com says that it's not out yet in the US.

Calum, how does one gain access to those archives? Do you have to have university credentials? Government approval/endorsement, pay a fee?I would just like to say that, having glanced through the book again today and seen the Me-409 pieces, I believe this to be one of the best value, if not THE best value military tech books ever and we will have to go a lot of country miles to even come close. Very grateful that this man went through so much to bring it to us and the price is a bleedin' steal.......

That was pure luck, I was in the DB corporate archives and happened to look in a folder called "Ringkuhler" - most of which was indeed fairly uninteresting images of front mounted ring-pattern radiators. However, I think because the 409 propnose has a "ring air entry" to the first stage supercharger, which looks a bit "Ringkühlerey" an achivist there way back in the day (probably prior to 1980s) just stuffed the "Me 409" photos in with it. I only had 2 full days there, and would have needed another 2 weeks to have surveyed every folder. It is suprisingly complete, although I think many later developments in the final chaotic year or so were not well catalogued or preserved, I "suspect" that may well be because by that time the design staff at Untertürkheim were all working remotely in various small repurposed factories at the outskirts of Stuttgart, and probably their drawings never made it back to the central plant. Hence why I only found the DB 603 N variable valve timing drawings with Dr Kollmann's son, and not at the DB archives.

I'm looking forward to your book, but amazon.com says that it's not out yet in the US.

At the time I was working for Mercedes F1 engines in Northampton, the guys there had contacts at Daimler-AG because the F1 factory sometimes made parts for some of the very rare vintage German racers which Daimler/Mercedes operate in Germany at their heritage facilites, so they introduced me. The fact I was writing a book and had by that stage given quite a few lectures on the topic probably also helped. I cant comment on what their official admissions policy might be.

- Joined

- 19 July 2016

- Messages

- 3,727

- Reaction score

- 2,690

The UK national archive may have some documents from the end of WW2, a LOT of paperwork and hardware, some may be available online.

www.nationalarchives.gov.uk

www.nationalarchives.gov.uk

The National Archives

We are a non-ministerial department, and the official archive and publisher for the UK Government, and for England and Wales.

- Joined

- 19 July 2016

- Messages

- 3,727

- Reaction score

- 2,690

As an F1 fan I would love to have been a fly on the wall at THOSE meetings. Unlikely I know.Calum, how does one gain access to those archives? Do you have to have university credentials? Government approval/endorsement, pay a fee?I would just like to say that, having glanced through the book again today and seen the Me-409 pieces, I believe this to be one of the best value, if not THE best value military tech books ever and we will have to go a lot of country miles to even come close. Very grateful that this man went through so much to bring it to us and the price is a bleedin' steal.......

That was pure luck, I was in the DB corporate archives and happened to look in a folder called "Ringkuhler" - most of which was indeed fairly uninteresting images of front mounted ring-pattern radiators. However, I think because the 409 propnose has a "ring air entry" to the first stage supercharger, which looks a bit "Ringkühlerey" an achivist there way back in the day (probably prior to 1980s) just stuffed the "Me 409" photos in with it. I only had 2 full days there, and would have needed another 2 weeks to have surveyed every folder. It is suprisingly complete, although I think many later developments in the final chaotic year or so were not well catalogued or preserved, I "suspect" that may well be because by that time the design staff at Untertürkheim were all working remotely in various small repurposed factories at the outskirts of Stuttgart, and probably their drawings never made it back to the central plant. Hence why I only found the DB 603 N variable valve timing drawings with Dr Kollmann's son, and not at the DB archives.

I'm looking forward to your book, but amazon.com says that it's not out yet in the US.

At the time I was working for Mercedes F1 engines in Northampton, the guys there had contacts at Daimler-AG because the F1 factory sometimes made parts for some of the very rare vintage German racers which Daimler/Mercedes operate in Germany at their heritage facilites, so they introduced me. The fact I was writing a book and had by that stage given quite a few lectures on the topic probably also helped. I cant comment on what their official admissions policy might be.

Last edited:

- Joined

- 31 May 2006

- Messages

- 648

- Reaction score

- 399

Got mine the other day. It was signed and it came in a useful blue bag.  I'm about 60 pages in, learned loads already. Thoroughly enjoying it. I'll post a full review when I get right the way through it - where would be the best place to do that? Mortons? Amazon? Goodreads? Allof the above?

I'm about 60 pages in, learned loads already. Thoroughly enjoying it. I'll post a full review when I get right the way through it - where would be the best place to do that? Mortons? Amazon? Goodreads? Allof the above?

Last edited:

Please do post a review once you`ve read it in full. The only slight complaints so far are a few typos and print-errors in the 1st print (we located about 22, which we`ve fixed entirely for the 2nd run now being printed), and that its fairly light on operational history.Got mine the other day. It was signed and it came in a useful blue bag.I'm about 60 pages in, learned loads already. Thouroughly enjoying it. I'll post a full review when I get right the way through it - where would be the best place to do that? Mortons? Amazon? Goodreads? Allof the above?

Pasoleati

I really should change my personal text

- Joined

- 29 June 2012

- Messages

- 496

- Reaction score

- 166

I have read about half of it now and as I have written elsewhere, it is the best WW2 aircraft related book I have ever read. Only Dean's AHT and Whitney's Allison book come even close.

That being said, I do still disagree about the sleeve-valve issue. That no "modern" engine has them is of no vital relevance because a. in many motor sports rules ban such valves (at least did so some years ago when I read the rules on engines on F1) and b. commercial engines' purpose is to bring maximum profits, not best engineering. One just needs to think how long American car manufacturers stuck to the inferior 2-valve OHV designs. Or think how the superior Beta lost to the VHS.

Interestingly regarding oil consumption , Ricardo does indicate in his book that the oil consumption decreased with engine life while the opposite occurred in poppet-valve engines.

Also interestingly, all Lancaster variants (Merlin and Hercules) had exactly the same-sized oil tanks. If the Hercules gulped more oil, the difference can't have been that significant.

Regarding the power comparison between the R-2800 and the Centaurus, one is blinded by one thing: the high ratings achieved in the P-47D (up to 2600 hp). But, and it is a big but, a purely mechanically supercharged variant running on 100/130 and no water-injection was pretty much stuck to 2000-2100 hp. The Centaurus did achieve some 2700 hp under same conditions. Post-war American radials generally used 115/145 while the Bristols were often running on 100/130.

I don't know yet does the book mention Japanese engines, but IMHO the most interesting comparison would be the Homare vs. BMW 801. The former much smaller, yet more powerful probably on inferior fuel.

And I would also love to see a Tempest V or a Typhoon with the Sable flying again!

That being said, I do still disagree about the sleeve-valve issue. That no "modern" engine has them is of no vital relevance because a. in many motor sports rules ban such valves (at least did so some years ago when I read the rules on engines on F1) and b. commercial engines' purpose is to bring maximum profits, not best engineering. One just needs to think how long American car manufacturers stuck to the inferior 2-valve OHV designs. Or think how the superior Beta lost to the VHS.

Interestingly regarding oil consumption , Ricardo does indicate in his book that the oil consumption decreased with engine life while the opposite occurred in poppet-valve engines.

Also interestingly, all Lancaster variants (Merlin and Hercules) had exactly the same-sized oil tanks. If the Hercules gulped more oil, the difference can't have been that significant.

Regarding the power comparison between the R-2800 and the Centaurus, one is blinded by one thing: the high ratings achieved in the P-47D (up to 2600 hp). But, and it is a big but, a purely mechanically supercharged variant running on 100/130 and no water-injection was pretty much stuck to 2000-2100 hp. The Centaurus did achieve some 2700 hp under same conditions. Post-war American radials generally used 115/145 while the Bristols were often running on 100/130.

I don't know yet does the book mention Japanese engines, but IMHO the most interesting comparison would be the Homare vs. BMW 801. The former much smaller, yet more powerful probably on inferior fuel.

And I would also love to see a Tempest V or a Typhoon with the Sable flying again!

I have read about half of it now and as I have written elsewhere, it is the best WW2 aircraft related book I have ever read. Only Dean's AHT and Whitney's Allison book come even close.

That being said, I do still disagree about the sleeve-valve issue. That no "modern" engine has them is of no vital relevance because a. in many motor sports rules ban such valves (at least did so some years ago when I read the rules on engines on F1) and b. commercial engines' purpose is to bring maximum profits, not best engineering. One just needs to think how long American car manufacturers stuck to the inferior 2-valve OHV designs. Or think how the superior Beta lost to the VHS.

Interestingly regarding oil consumption , Ricardo does indicate in his book that the oil consumption decreased with engine life while the opposite occurred in poppet-valve engines.

Also interestingly, all Lancaster variants (Merlin and Hercules) had exactly the same-sized oil tanks. If the Hercules gulped more oil, the difference can't have been that significant.

Regarding the power comparison between the R-2800 and the Centaurus, one is blinded by one thing: the high ratings achieved in the P-47D (up to 2600 hp). But, and it is a big but, a purely mechanically supercharged variant running on 100/130 and no water-injection was pretty much stuck to 2000-2100 hp. The Centaurus did achieve some 2700 hp under same conditions. Post-war American radials generally used 115/145 while the Bristols were often running on 100/130.

I don't know yet does the book mention Japanese engines, but IMHO the most interesting comparison would be the Homare vs. BMW 801. The former much smaller, yet more powerful probably on inferior fuel.

And I would also love to see a Tempest V or a Typhoon with the Sable flying again!

I thank you for your comments, I agree with you 100% that it is essential that unusual and rare aero engines like the Sabre and Centaurus be put back into flight.

I`m not here to stop anyone liking any aero engine, merely to illustrate some reasons why things happened the way they did. If, after reading the book

you still feel as you do now about sleeves, then all I can say is that I`m pleased the technology has very dedicated fans - as that will help with future

restorations of the type.

Similar threads

-

Messerschmitt Me 309 Development & Politics by Dan Sharp and Calum E. Douglas

- Started by newsdeskdan

- Replies: 57

-

Killer Rays: Story of the Douglas F4D Skyray & F5D Skylancer

- Started by overscan (PaulMM)

- Replies: 14

-

-

The Aircraft Projects of Commonwealth Aircraft Corporation by Joe Vella

- Started by GTX

- Replies: 13

-

Eyes in the Sky: Eisenhower, the CIA and Cold War Aerial Espionage

- Started by overscan (PaulMM)

- Replies: 0