F-2

ACCESS: Top Secret

- Joined

- 22 May 2020

- Messages

- 692

- Reaction score

- 1,204

https://baike.baidu.com/item/涡扇-6/888881Development process

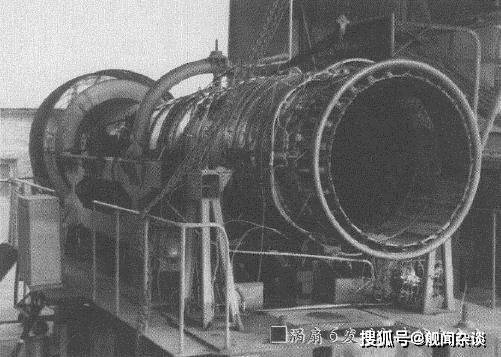

In May 1964, the Chinese Air Force put forward technical requirements for designing a new type of aircraft that is more advanced than the J-7 fighter plane. Since then, the Shenyang Aircraft Research Institute and the Shenyang Aeroengine Research Institute have begun program research. In October of the same year, the two institutes put forward a preliminary plan for new aircraft and engines. After discussion by the air force and the aviation industry departments, it was decided that the design of the new aircraft should be divided into two steps. The first step is to design a new aircraft equipped with two improved turbojet engines, namely, the later J-8 aircraft and the WP-7A engine. The second step is to design a more advanced high-altitude high-speed fighter (J-9) equipped with a newly designed supercharged turbofan engine, the new engine numbered turbofan-6, code-named WS-6. In September 1965, WS-6 completed the demonstration of the scheme and began technical design. In May 1966, it was put into trial production.

In June 1968, the first test machine began to run the platform for testing. In October 1980, the performance of the WS-6 reached the design target. In October 1982, the 24-hour pre-flight test was passed. The whole machine was tested for a total of 334 hours. After the 1980s, the national policy turned to economic construction, compressed military investment, and dismounted the J-9 fighter jets supporting the WS-6. The WS-6 lost its suitable target and lacked further investment. It stopped its research and development in 1984.

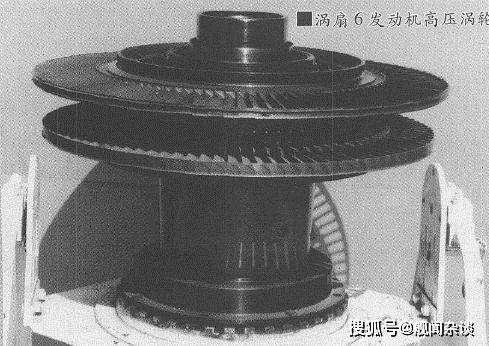

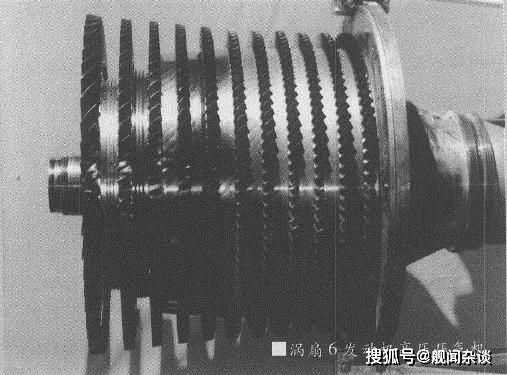

The turbofan-6 is designed for the technical requirements of high-altitude high-speed fighters. In terms of engine parameters and control plans, full attention has been paid to improving the engine push-weight ratio and high-speed performance. High turbine inlet temperature and nearly optimal total supercharger ratio are selected, and cross-sonic fans, air-cooled high-temperature turbines and parallel intake intake increment combustion chambers are adopted. A control plan that can give full play to the advantages of high-altitude and high-speed performance is selected. The engine is characterized by high-speed thrust, good subsonic cruise economy, fast start-up and acceleration. The rotor adopts a 5-fulcrum support scheme, with a compact structure and reasonable layout, and more titanium alloy materials are used. Therefore, the weight of the engine is light, and the proportion of push weight is large.

In the process of development of turbofan 6, there have been a large number of technical problems, among which the main ones are: difficulty starting, compressor surge, high turbo inlet temperature and large vibration. The main reason is that in the early stage of self-development, there is a lack of technical reserves, and the experimental research of main components is insufficient, especially the low efficiency and shortness of the gasp of the core compressor components, which brings many difficulties to debugging. After many modifications, tests and repeated debugging of the main components on the whole machine, a lot of work was done, and by the end of 1980, the components and overall performance had reached the design targets.

WS-6 compressor

In 1980, the improved WS-6 (adnamed WS6G) was developed on the basis of WS-6. The improvement work is mainly to increase the maximum incension thrust of the engine to 138.2 kn, the maximum thrust to 83.3 kn, and the thrust ratio to 7.05, which greatly improves the performance compared with WS6, and in terms of reliability, maintenance and fuel consumption. The aspect remains unchanged. Compared with the original design, the low-speed rotor speed was increased. The fan was changed from level 3 to stage 2, but its pressure ratio was increased from 2.15 to 2.6, so the culvert ratio decreased. At the same time, the inlet temperature of the turbine has been raised, and the original ring combustion chamber has been changed to a circular combustion chamber. Under the condition that the outer profile size is the same as the WS6 and the mass is reduced by 100kg, the aggravating thrust of the design state increased by 13.2% and the thrust ratio increased by 18.9%. [ 1] In February 1982, the first WS6G conducted a ground test. The measured maximum thrust and intensive thrust reached the expected index, and it could carry out a real flight test, paving the way for its further development. However, in the early 1980s, due to changes in the air force equipment system, J-9 and Q-6 aircraft are planned to cancel one after another, and the WS-6, which is its supporting power, has lost its object of use. In July 1983, the development of the turbofan-6 engine was completely suspended, and in early 1984, the development plan was cancelled.

This turbofan engine with excellent performance and great development prospects has been cancelled, making China miss the turbofan engine again and miss the opportunity to narrow the gap with the world's advanced level again! In 1970, in response to the needs of transport engine development, the WS-6A (i.e. 910A) engine was developed, using a single-stage fan and an intermediate compressor, which increased the total air flow rate and culvert ratio without force. Three test machines have been produced. Later, due to the change of aircraft development plan, the development was stopped in 1973. The performance of theWS-6 is comparable to that of Spey MK-202 and M53. WS-6G is higher than the above two engines. While the good news of WS-6 research and development is spreading frequently, the air force is optimistic about the introduction of Spey MK-202, which once again has brought a heavy blow to the national aeroengine industry. In the process of research and development, WS-6 has developed 15 new materials, 8 new accessories, 17 new processing technologies, and established many experiments and supporting facilities. However, with the cancelling of this type of engine, the technology has not been inherited and continued. Nevertheless, WS-6 still has a milestone in the history of China's aviation industry.

Performance parameters

Factory Shenyang Aeroengine Research Institute/Shenyang Dawn Engine Manufacturing Company

Production status After completing the pre-flight test, stop research and development.

Installed object Vortex Fan 6 Fighter

Vortex fan 6G fighter

Vortex Fan 6A Transporter

Technical data Maximum additive thrust (kg)

WS6 12,220

WS6G 13.,830

Intermediate thrust (kg)

WS6 7,130

WS6G 8,385

WS6A 10,169

Afterburner fuel consumption rate

WS6 2.3045

WS6G 2.338

Intermediate fuel consumption rate

WS6 0.6342

WS6G 0.7850

WS6A 0.6000

Thrust/weight ratio

WS6 5.93

WS6G 7.05

WS6A 4.69

Air flow (kg/s)

WS6 155.0

WS6G 151.2

WS6A 274.5

Bypass ratio

WS6 1.0

WS6G 0.633

WS6A 1.74

Total pressure ratio

WS6 14.60

WS6G 17.50

WS6A 19.72

Turbine inlet temperature (°C)

WS6 1077

WS6G 1207

WS6A 1107

Maximum diameter (mm)

WS6 1370

WS6G 1370

WS6A 1460

Length (mm)

WS6 5645

WS6G 4654

WS6A 3080

Weight (kg)

WS6 2100

WS6G 2000

WS6A 2210

Looking back on the difficult process of domestic aeroengine research and development, we can't help mentioning the turbofan 6 engine. This is the first supercharged high-thrust turbofan engine developed by China in the 1960s, which is of great significance in the history of China's aviation industry. However, the development process of Vortex Fan 6 was very tortuous. It was dismounted three times, four times, five transfers the production unit, and finally dismounted in the early 1980s.

In May 1964, Shenyang Aeroengine Design Institute began to design turbofan 6. Before the design, the technicians made a detailed demonstration, referring to the turbine and main combustion chamber of the Spell civilian (MK511/512), the compressors of turbojet 7 and turbojet 8, and many technologies of the J79 turbojet engine in the United States. After more than 10 structural layouts and 7 pneumatic schemes, the overall design scheme was determined by Vortex Fan 6.

In the early 1960s, turbofan engines around the world were just in their infancy, and the development direction and technical indicators determined by turbofan 6 were relatively advanced at that time. It adopts a 2-stage transonic fan, a 11-stage high-pressure compressor, a level 1 guide blade adjustable, a ring tube combustion chamber, a 2 stage high-pressure and a 1 stage low-pressure turbine, a high-pressure guide blade and working blade are hollow air-cooled blades, a parallel intake mixed intensive combustion chamber, and a convergent stepless adjustment nozzle. The afterburning thrust is 12.64 tons, the maximum state thrust is 7.27 tons, and the thrust ratio is 5.93. The overall data is almost the same as that of the British "Spey" at that time.

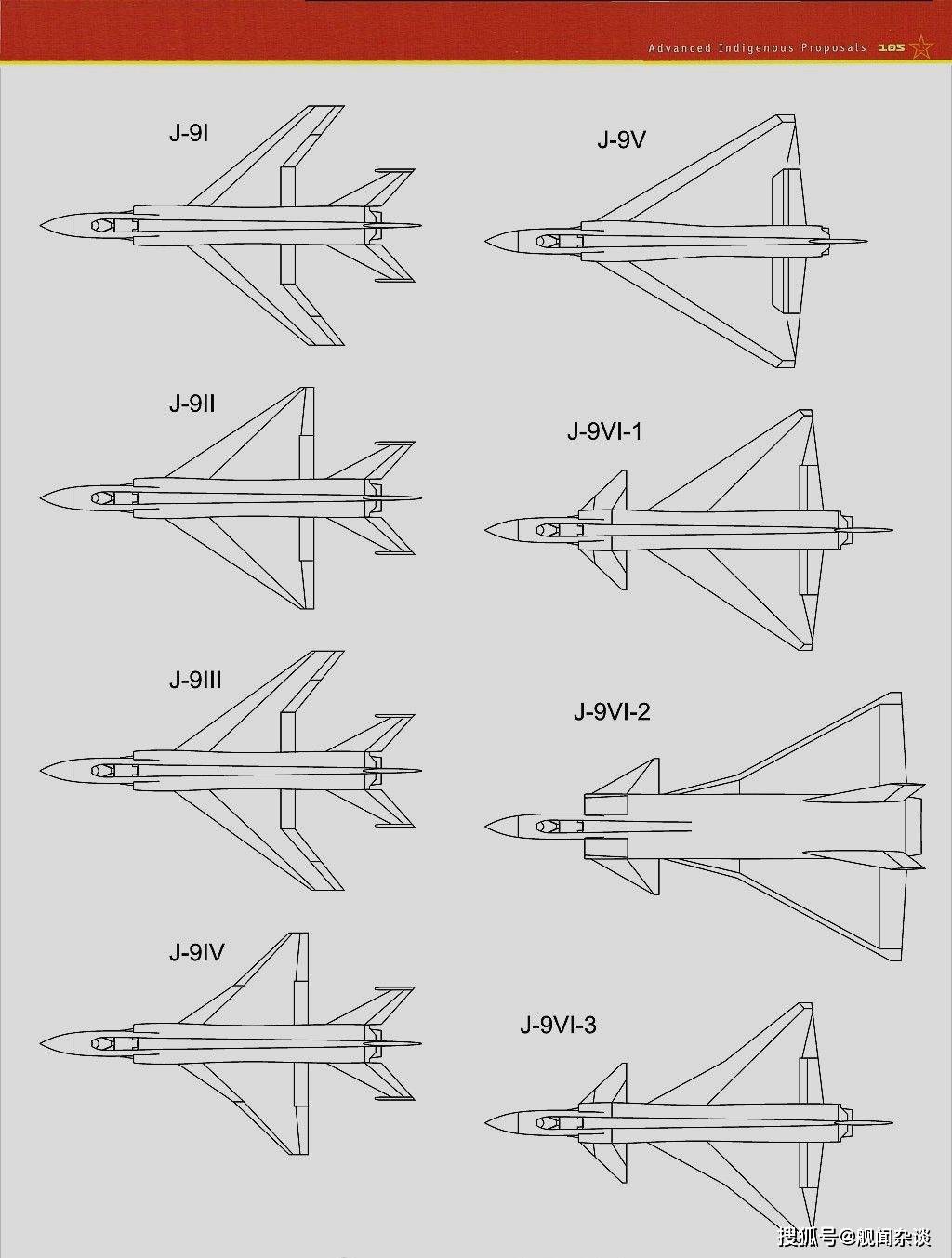

In August 1966, the high-level approved the turbofan 6 as the power device of the J-9 fighter jet. The J-9 is actually two projects established at the same time as the J-8 and developed in parallel. They are all high-altitude high-speed interceptors. However, at that time, grandeur was prevalent. For the design indicators of the aircraft, the maximum lift limit ranged from 20,000 meters, 25,000 meters to 30,000 meters, and the maximum speed reached Mach 2, Mach 2.5 or even Mach 3. In February 1968, the first test machine of WS-6 was assembled.

In April 1969, in order to concentrate on the "Double Three" aircraft, the Party Committee of the Air Force decided to dismount the J-9. In fact, not only we can't meet the "Double Three" technical indicators, but also the Soviets can't. Just five months later, in September, the Air Force Party Committee decided to continue to develop the J-9. By November, the second test machine had been assembled.

In February 1971, in order to concentrate on the development of turbofan 6A engine, it was decided to suspend the development of turbofan 6.

In September 1971, it was decided to continue the development of WS-6.

In April 1972, in order to concentrate on imitating the Spey engine, it was decided to suspend the development of WS-6.

In December 1976, with high-level approval, the development of WS-6 continued as a power plant for J13.

In March 1978, the third test machine was assembled.

In January 1981, the WS-6 successfully passed a 24-hour continuous ground long-term test, and met the conditions for installation test flight. By April 1983, seven more test machines had been produced in four batches.

In 1984, the air force's equipment system changed significantly. The J-9 and Qiang-6 projects were successively dismounted, and the development of the WS-6 as its supporting power was also terminated.

Looking back on the development process of WS-6, that period was almost the most chaotic period, and even the production site was changed five times. In 1966, the trial formulation point of WS-6 was in Shenyang 410 Factory. By the end of 1967, it was transferred to Zhuzhou 331 Factory for trial production. In July 1969, it was transferred back to Shenyang 410 Factory from Zhuzhou, 197 In June 2, it was transferred from Shenyang 410 Factory to 624 Sichuan Jiangyou, and in May 1974, it was transferred from 624 Sichuan Jiangyou to Shenyang 410 Factory. This strange experience of "three ups, four downs, five shifts" is unimaginable now.

Under that chaotic system, it is also common to change the performance indicators of the equipped model frequently. Sometimes it is required to highlight the performance of subsonic speed and transonic speed, and sometimes it is required to achieve the "double three" index of 30,000 meters ceiling and a speed of Mach 3. This whimsical idea makes engineers at a loss.

There is also a point of view that persistence is victory. The research and development ofWS-6 goes back and stop, and then step back and forth again and forth, and continuously postpones. If we persist again and invest a certain amount of money, it may be done. And give the example of land-based mid-stage anti-missile. We have always insisted that the current level has put pressure on the United States. This view is not completely correct. The most important point is that the technical difficulty of aeroengines is much more difficult than that of rocket engines. Rocket engines are disposable, while aeroengines have cycle life and stricter requirements in materials, machining level, assembly technology, reliability, etc.

From the beginning of program research in 1964 to the dismountation of the project in 1984, WS-6 has gone through 20 years, which consumed almost a generation of youth. According to the hindrance of the relevant personnel, the moment the superior announced the suspension of the development, the designer burst into tears and cried on and off the stage.

In addition to WS-6, there are also many projects such as WS-8, Yunshi, etc., which are very regrettable from the perspective of scientific researchers, but from the perspective of decision-making, it is undoubtedly correct to dismount. Scientific research, especially military research, must follow the laws of science itself, and many problems cannot be solved by political leadership.

手机搜狐网

Last edited by a moderator: