- Joined

- 16 April 2008

- Messages

- 8,357

- Reaction score

- 10,193

I know a little the story you're talking about. Sometime in the 90s a SecDef and the SecUSAF had proposed the usaf field a stealthy swing low altitude penetrator to take over the role of the retired F-111and to replace the strike eagle. It went no where. They allegedly wanted to buy something like 400 of these monsters. What we got instead was more funding for the JSF and the super hornet. Its probably in a book i read and others here can probably correct me if I recall this wrong.

If its true then its awfully revealing that the problems of swing wings and stealth are solvable and the US stealth know how has moved beyond simple shaping. At least that’s what I read into it.

Sounds a bit like the mythical A-17 that as far as I know was only mentioned in Popular Science.

Popular Science

Popular Science gives our readers the information and tools to improve their technology and their world. The core belief that Popular Science and our readers share: The future is going to be better, and science and technology are the driving forces that will help make it better.

books.google.com

Last edited:

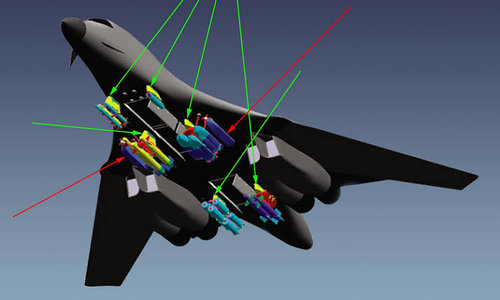

![Rhfv8q4sUCzAfjmo.mp4_snapshot_00.00_[2020.09.03_17.58.33].jpg](/data/attachments/176/176225-e8d6ff91d39765fc1eb16983fd7b0b5a.jpg)

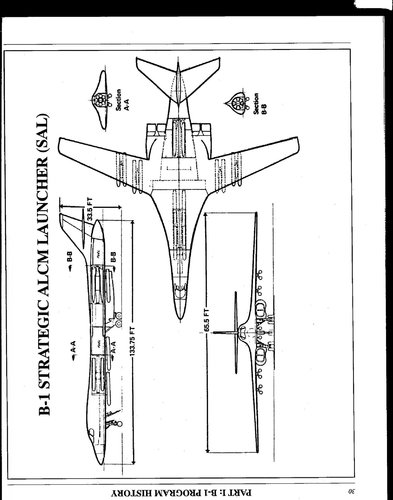

![Rhfv8q4sUCzAfjmo.mp4_snapshot_00.07_[2020.09.03_17.58.54].jpg](/data/attachments/176/176226-f1a41cbb2ccc0cccbf44f20bdbfeddd0.jpg)