George Rosen was a Massachusetts Institute of Technology (MIT) graduate aeronautical engineer, class of 1937,who went to directly to work for Hamilton Standard as their first propeller aerodynamicist. George had long and distinguished career at Hamilton Standard, winning the United Aircraft Mead Medal in 1961 for the variable camber propeller and the Goddard Award from the American Institute of Aeronautics and Astronautics (AIAA) in 1975 for his many contributions to the turbine propeller. Rosen retired as Chief of Propeller Research and Development in 1977after forty years of service that spanned the heyday of the propeller. He was also a great patron of the arts and an accomplished sculptor late in his life.

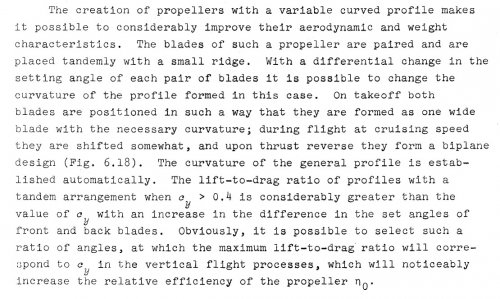

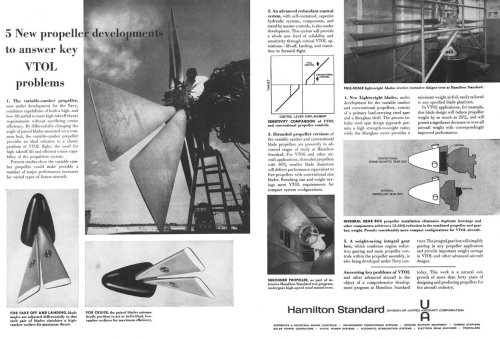

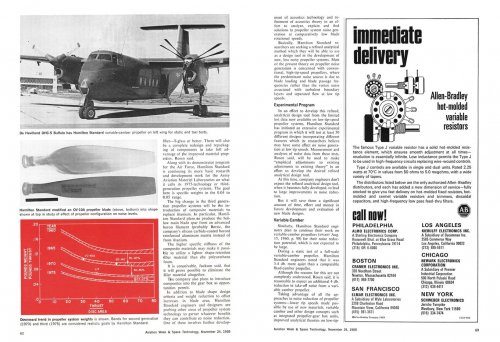

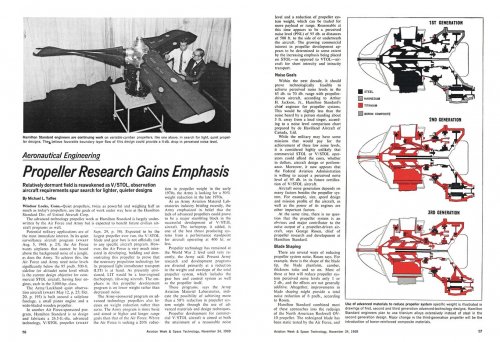

Propeller design is typically optimized for a specific phase of flight, most often, efficiency in high speed cruise. One of the ongoing challenges of propeller propulsion is to provide the ability for high thrust for take-off with high thrust but low drag for cruise flight. Highly cambered propellers generate tremendous thrust at low airspeeds, but are draggy and thus inefficient in the high speed flight regime. Very thin propeller blades work well at high speed cruise, but have reduced thrust profiles at low airspeeds such as take-off. Variable pitch, constant speed propellers address this challenge quite well as long as runways are sufficiently long. But what about optimizing performance for missions that require short take-off and landing (STOL) or vertical take-off and landing (VTOL)?

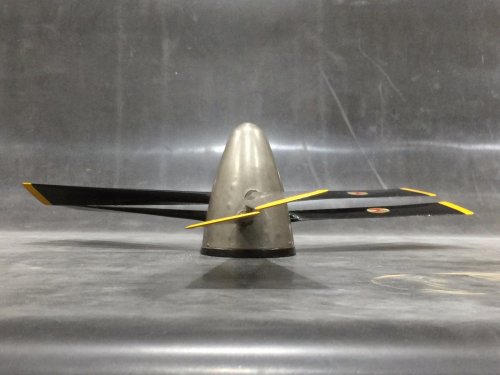

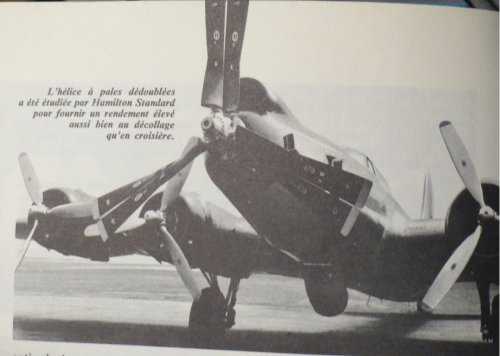

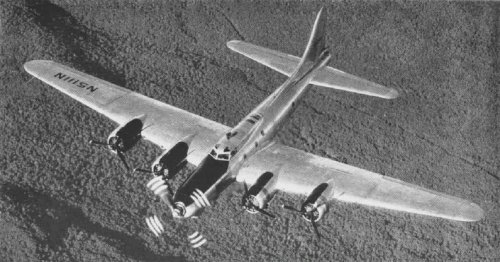

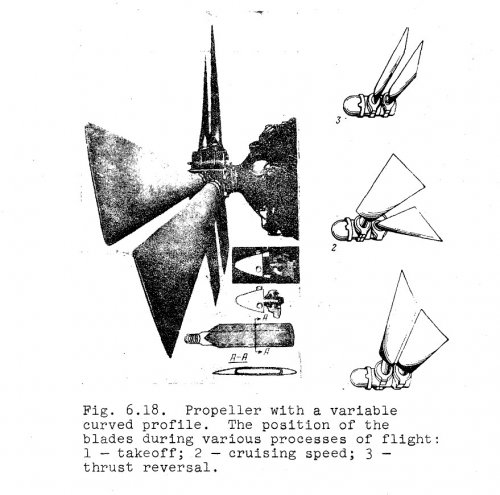

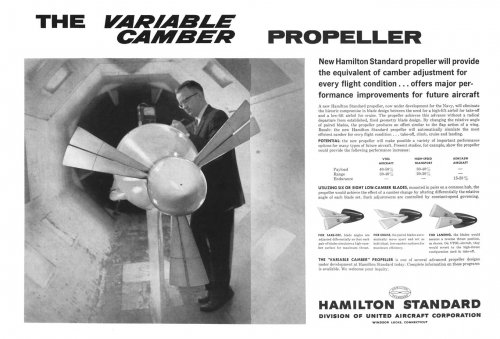

George Rosen conceptualized an engineering approach to this “high thrust at low airspeed but efficient cruise" requirement with the variable camber (VC) propeller. His idea was to use two rows of propeller blades on the same single-rotation hub. The aft propeller disc would be displaced axially behind the fore prop disc, and the blades themselves would be offset by 25°between the rows. The pitch of each disc (row) of propeller blades could be adjusted independently of each other. (Fig. 6) This allowed the trailing blade to perform essentially as a slotted flap to the leading blade. George Rosen submitted a patent application for his invention on 19 December1958 and was granted US Patent 2,982,361 on 2 May 1961.

[..]

References

Thrusting Forward: A History of the Propeller, by George Rosen with Charles A. Azenis, published by the Hamilton Standard Division of United Technologies Corporation, 1984.

Variable Camber Blading, US Patent 2,982,361 , granted May 2, 1961, to George Rosen, assignor to Untied Aircraft Corporation.

Two Part Pitch Changing Mechanism, US Patent 3,163,231, granted Dec. 29, 1964, to Phillip E. Barnes, Seppo J. Viikinsalo, and Richard B. Pitbladdo, assignors to United Aircraft Corporation.

“Propeller Integral Gearbox 73EGB1 and Propeller Variable Camber Model VC86260 Flight Test Report”, Report HSER 4076 , Bureau of Naval Weapons Contracts NOw-64-0635-di and NOw-65-0533-d, 30 June 1966.

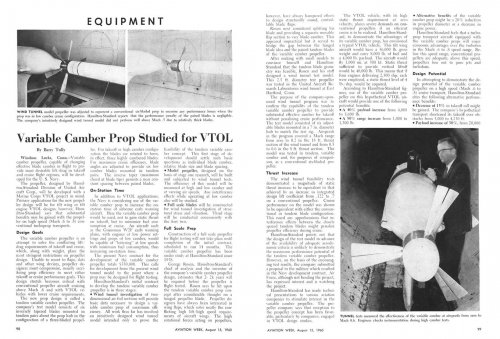

Variable Camber Prop Studied for VTOL by Barry Tully, Aviation Week , 15 August 1960, pages 98, 99, and 101.

Propeller Research Gains Emphasis by Michael L. Yaffee, Aviation Week and Space Technology , 24 November 1969, pages 56, 57,62,63,64.

Advertisement by United Aircraft International, Flight International , 30 April 1964, page 4.

Obituary for George Rosen, Hartford Courant, 16 June 2004.

"Unusual Propellers" by John Leonard, Rolls-Royce Heritage Trust Allison Branch Newsletter , December 2010.

"Next Generation V/STOL Propellers" by George Rosen and William M. Adamson, SAE Transactions Vol. 77, Sec. 2, paper 680248-68434, pages 893-905, 1968.

Advanced Propeller Concepts ... Developed Today (Windsor Locks, CT: Hamilton Standard, 1965).