Lascaris

ACCESS: Secret

- Joined

- 14 November 2008

- Messages

- 271

- Reaction score

- 312

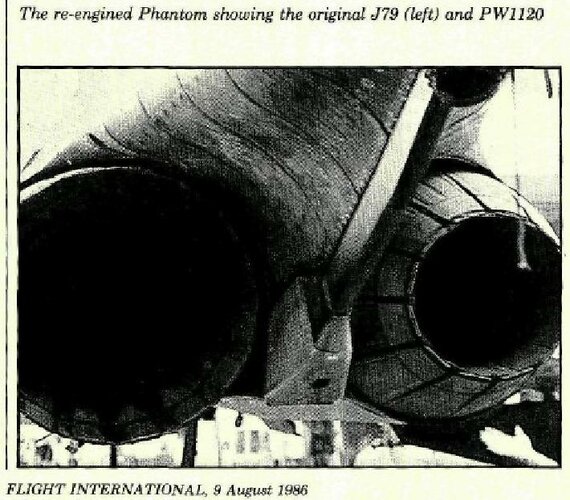

I'm am trying to understand the logic behind choosing to develop PW1120 to power the Lavi as opposed to using an already existing engine. PW1120 was rated at 3530/20585 lbf. By comparison the F100-PW220 was rated at 14590/23770 lbf and on the other side of the spectrum the F404 17-18,000 lbf counting on the exact version.

So why would Israel choose on powering Lavi, already a very ambitious project for its size as it was with a new engine on top of it, even one derived from an existing one instead of just going for F100 which it already operated with F-15 and F-16? Or alternatively going for an F404 powered design? What was to be gained that actually justified the additional costs, complexity and potential risks of developing a separate engine?

So why would Israel choose on powering Lavi, already a very ambitious project for its size as it was with a new engine on top of it, even one derived from an existing one instead of just going for F100 which it already operated with F-15 and F-16? Or alternatively going for an F404 powered design? What was to be gained that actually justified the additional costs, complexity and potential risks of developing a separate engine?