Mortars of Unusual Design

While the 4.2" mortar was the workhorse of CWS troops during WWII, members of the technical staff experimented with other models. Following a suggestion of the Chemical Warfare Board in 1943 that fewer mortars would be needed and targets could be changed more rapidly if the weapon could swing through a full circle, engineers began development of a special mortar with a traverse of 360º.

They designed several models, one or more of which might ultimately have been satisfactory, but finally dropped the project when the AGF [Army Ground Forces] decided that a mortar with such an extreme traverse was unnecessary. Along with the 360º mortar , the men experimented with a mortar of 90º traverse but the weapon was not particularly successful and the project ended with the war.

To simplify the training of mortar squads, the Chemical Warfare Board devised an ingenious subcaliber mortar consisting of a steel pipe that fitted inside the standard mortar barrel. The shell was fashioned of steel and wood and could be used over and over. The weapon was fired in the usual manner and ranged from 115 to 400 yards. S mall glass bottle of smoke solution could be fitted to the nose to give the appearance of a miniature explosion when the shell landed. Not the least of the merits of this subcaliber mortar was that it dropped the cost of firing a training round of ammunition from several dollars to thirteen cents.

In 1943, at the suggestion of Col. William A. Borden, Ordnance Department, who had conducted a survey of munitions in the Pacific Island, the CWS began to develop a mortar which could fire horizontally into low Japanese bunkers of coconut logs and earth. The standard mortar barrel could not be dropped below an angle of 45º with the horizon, and a way had to be found of holding the barrel level with the ground and at the same time neutralizing the tremendous recoil of a quarter of a million pounds. Engineers at the CWS Laboratories at Columbia University devised a method of leveling the mortar by a new baseplate that could be bolted or chained to the trunk of a tree.

While this solved the recoil problem, as long as mortar companies fought in wooded areas, it did not end the development work. When a mortar fired on a flat trajectory, for which it had never been designed, unusual strains were set up in the weapon. These had to be overcome by redesigning certain components. Even the shell was modified and its weight increased. Tests proved that the new model would be satisfactory in the field, but the weapon was not carried beyond the experimental stage because a recoilless mortar, which the CWS had started to develop at almost the same time, offered a better possibility of solving the multitude of problems that accompanied the change from angular to horizontal firing.

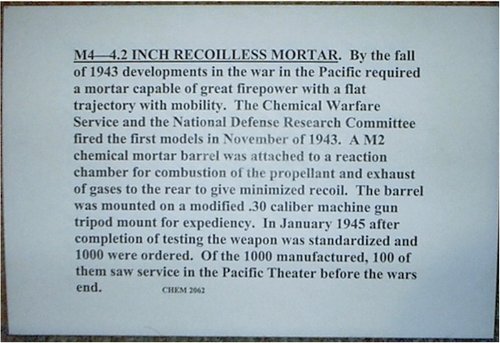

A recoilless gun was open at both ends instead of one end as in the conventional gun. When the propellant charge exploded, the shell sped forward through the barrel while the gas blew backward through the breech. The gun, shell and propellant were designed to make the forward action equal to the backward reaction, eliminating recoil.

Recoilless weapons had been investigated by the American Army in WWI. In WWII the idea was revived by the Germans, the British and then by the Ordnance Department. When the CWS began development of a horizontal mortar, it realized that the principle involved in a recoilless gun might be applied and, in October 1943, Gen. Kabrich asked Dr. C. N. Hickman, chief of section H, division 3, NDRC, to undertake the development of a mortar having no recoil. That same month, the first recoilless attachment to fit on the breech of the standard mortar was designed and, in November, firing trials were started.

Step by step, the ignition system, firing mechanism, reaction chamber and shell were perfected. The shell was fired in the usual manner. A small rocket, called a rocket driver by the designers, was attached to the fuze. When the mortar was fired, the rocket driver hurled the shell back into the barrel where it struck the firing pin. The firing pin then detonated the propellant charge and started the shell forward. The rocket driver fell off while the shell was in the air, exposing the fuze.

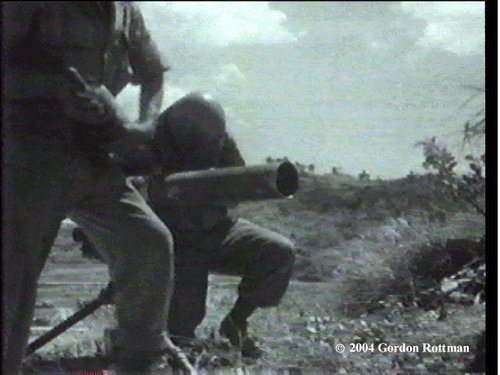

By August 1944, the model was ready for a full-scale demonstration at Edgewood. Service officers were so impressed that they ordered the gun completed under top priority. The final, standard model consisted of a two-piece barrel mounted on a caliber .30 machine gun tripod. Targets 3800 yards away could be hit but accuracy was best below 1000 yards. The 28-lb HE shell easily demolished replica Japanese bunkers of earth and logs.

The CWS contracted for the manufacture of 1000 recoilless mortars, 100 of the weapons being completed before the end of the war. Recoilless mortars reached the Tenth Army in the Pacific theater in time for the Okinawa campaign, but otherwise they were produced too late for battle use.