- Joined

- 3 January 2006

- Messages

- 956

- Reaction score

- 389

https://www.uasvision.com/2018/06/05/china-to-develop-large-payload-cargo-drone/

Before anyone gets too excited, it's worth pointing out that the concept has the same approximate MTOW as a de Havilland DHC-3 Otter, as well as the same 9 passenger capacity.

They plan to finalize their design before year’s end and construct a prototype in 2019 for test flights scheduled to start in 2020. Mass production will begin if test flights are successful, and a drone-based delivery network is expected to take shape around 2025, said Zhang Shuo, chief designer at the Beihang technology company, in an exclusive interview with China Daily.

The yet to be named drone will be so big that if it were to carry people, it easily would hold nine passengers, according to the company.

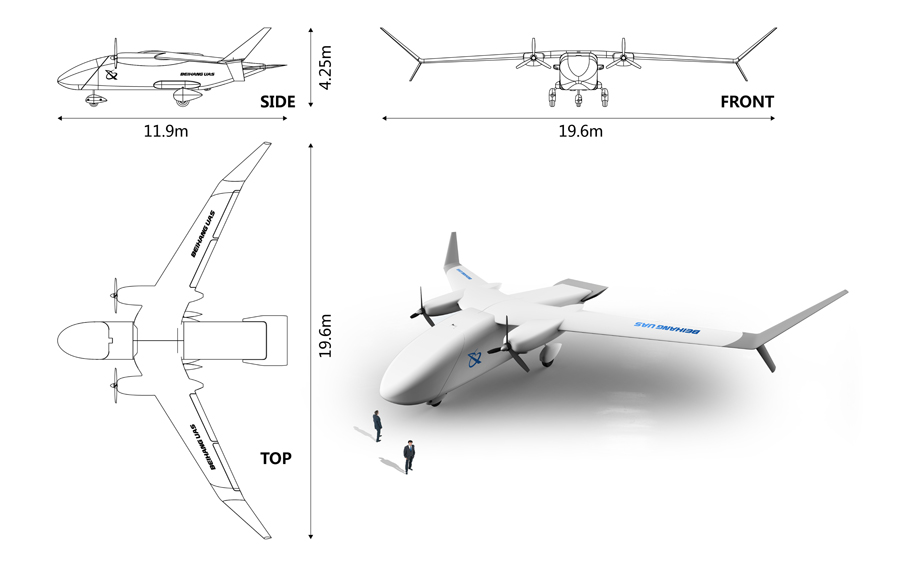

It will be 11.9 meters long, with a wingspan of 19.6 m, and have a maximum takeoff weight of 3.6 tons. The craft will be powered by two engines and have 16 cubic meters of cargo space.

Before anyone gets too excited, it's worth pointing out that the concept has the same approximate MTOW as a de Havilland DHC-3 Otter, as well as the same 9 passenger capacity.