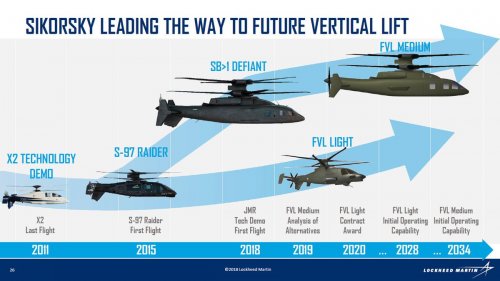

Installation of its eight 30-foot-long rigid rotor blades is all the SB-1 Defiant needs to be a complete compound helicopter scheduled for a first flight before the end of the year.

“Defiant has been completely built, minus the rotor blades,” Rich Koucheravy, Sikorsky’s future vertical lift director, said Oct. 8 at the Association of the U.S. Army’s annual expo in Washington, D.C. “We have run nearly all of the aircraft systems, so not only have the individual components been put through bench testing, but now we’ve got the aircraft completely configured. We’ve run the engines, we’ve run the electrical system. We’ve run the hydraulics. We’ve even turned the transmission without blades.”

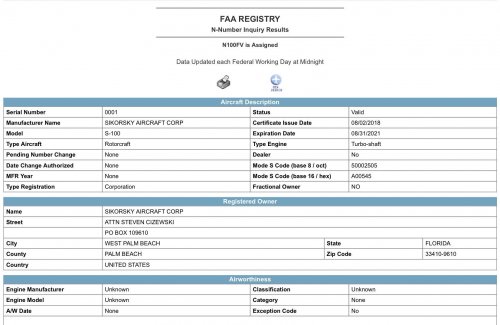

Half of the aircraft’s eight 30-foot rigid rotors will arrive at Sikorsky’s West Palm Beach, Florida, flight test facility by Oct. 9, said Boeing FVL Program Manager Ken Eland. The other four will arrive by next weekend.

Prior to first flight and during ground runs, engineers will gain hundreds of hours of system performance data from the powertrain systems test bed, which is essentially a replica of the Defiant that stays bolted to the ground and contains all of the dynamic systems configured exactly as they are in the aircraft. It has been run twice without the eight rigid rotor blades installed, according to Ken Eland, Boeing’s FVL program manager. It’s aft propulsor blades are installed.

The main rotor blades for the test bed have been delivered to West Palm Beach, but have not been installed, Eland said. The plan is to run the powertrain test bed once more before installing the blades. At that point, the test bed will start at zero and will be run a total 200 hours before the Defiant takes off, Eland said.

Koucheravy said the test bed should be fully up and running before the end of October. It will operate concurrently with Defiant ground runs, which should begin in November. The companies are eyeing a first flight in December.

“Between Sikorsky and Boeing, we have worked tremendously hard over the past six months to remove as much risk … from the program to get our aircraft up in the air,” Koucheravy said. “We remain on a path to complete the build of Defiant shortly and get it in the air by the end of the year.”

If the Defiant breaks contact with the ground in December, it will be about a year later than originally planned. That delay was primarily due to problems with automating the layering of fibers to create the central spar of the blades.

“We took the approach to automate the core part of this blade, so the spar is very long. It’s very thick and it’s composite material,’ Eland said. “To set the precedent for the future, of being a low-cost aircraft, we went right in with an automated approach to doing that. It was actually tooling for the rotor blades that set that back for a while.”

Because Boeing was developing the rotor lamination process — called automatic fiber placement — as it went, it took two years to build the first rotor spar. The last one took just 11 days, Eland said.

The same rotor configuration has flown in smaller scale on Sikorsky’s experimental X2 aircraft and on the S-97 Raider. The airfoil design is proven, said Randy Rotte, Boeing's director of business development for cargo helicopters and future vertical lift programs.

“It’s not about the airfoil challenges there,” Rotte said. “It really was about the process that we embarked upon — by the way at the request of the Army — to improve the manufacturing readiness level of that process and the discoveries we made on how to do that, which, yes, took us way longer than we expected because we ran into unexpected challenges.”

If Defiant lifts off in December, Eland said it could be flying at upward of 200 kt by mid-2019 as part of a gradual, phased flight test program that has been worked out in cooperation with the Army. A six-month “window is not an unrealistic time period for us to get there.”

“The true answer is when the aircraft says it’s ready, we’ll get there,” Eland said. “It’s a little hard to predict with what we’re doing. We have a revolutionary technology. … Expanding the flight envelope is going to be step-by-step to make sure that we do it safely and properly. To assign timelines to it at this time would be a little naive on my part.”