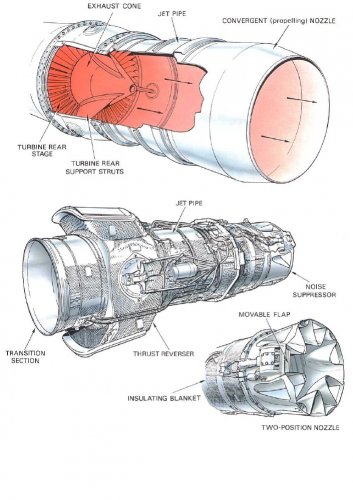

I think these pictures are of the Rolls-Royce Avon RA 29 with thrust reverser for the Comet; the flap on the noise suppression nozzle may be to slow the at T/O -wide open - then may close to increase thrust as the aircraft leaves the airport environs. The thrust reverser is explained in Flight- see below.

Another (better) explanation:

Jet noise became an important environmental factor with the introduction of commercial transports powered by turbojets in the mid 1950s. These engines were noisy by any standard, and whereas the pioneer Comet 1 and Tu104 had plain jet pipes, the Comet 4, 707 and DC-8 were all provided from the outset with exhaust nozzles which promoted more rapid mixing of the jet with the atmosphere. The objective was to maximize the length of the nozzle periphery.

In the Avon engines of the Comet and Caravelle the exhaust nozzle (named for F. B. Greatrex of RollsRoyce) had an expanding diameter so that, whilst keeping cross-section area constant, it could incorporate six large inward-pointing chutes bringing fresh air to mix with the jet. In the DC-8 and Conway-engined 707 the jet was diverted outwards by internal vanes to escape through eight radial lobes. The effect with this corrugated-perimeter nozzle was the same as with the Greatrex but even more pronounced. With the Pratt & Whitney-engined 707 the exhaust nozzle was terminated in 20 separate circular tubes.

In the Avon 531 of some Caravelle VIs the nozzle was fitted with a hinged flap between two of the lobes to trim area to different flight conditions. Concordes have unique exhaust nozzles, the inner primary petals having retractable 'spades' to break up the periphery and the outer (reverser) eyelids, in effect squashing the jet on take-off to reduce noise.

All of these exhaust nozzles had little effect on the high-frequency noise from immediately downstream (in fact, by lengthening the periphery they mostly increased it), but this noise is rapidly attenuated by the atmosphere, and some that may reach the listener is beyond the audible range of frequencies.

Their main achievement was to reduce the more enduring lower-frequency noise. The fact that they were heavy and also degraded engine performance was obvious, and by modem standards the aircraft were still unacceptably noisy.

Article Source: http://EzineArticles.com/2126786