- Joined

- 19 February 2007

- Messages

- 1,102

- Reaction score

- 1,519

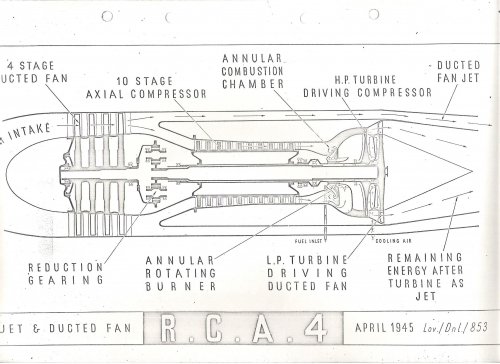

With the emergent success of Pratt & Whitney's Geared TurboFan (GTF Family) the question occurs to me - was there a geared turbojet design that made it to hardware? Indeed - were there any geared turbojet designs put forward?