You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lockheed Martin F-35 Lightning II Joint Strike Fighter (JSF)

- Thread starter Triton

- Start date

-

- Tags

- f-35 lockheed martin stealth usa

- Joined

- 25 June 2009

- Messages

- 13,768

- Reaction score

- 3,027

flateric said:quite a rare pic I think

Thanks for sharing! Wish it was HD... Never realized the X-31 was that small compared to the X-32 and X-35!

- Joined

- 9 November 2008

- Messages

- 1,070

- Reaction score

- 137

Massive update to the Flight Test at Edwards

http://www.codeonemagazine.com/article.html?item_id=117

http://www.codeonemagazine.com/article.html?item_id=117

F-35 Flight Testing At Edwards

By Eric Hehs Posted 17 May 2013

The first thing members of the F-35 Integrated Test Force see when they walk through the main entrance to the hangar at Edwards AFB, California, is a large flat screen display with a list of flight test priorities. The items on that list can change from one day to the next.

“Stability is crucial to successful test execution, but we can turn on a dime if priorities shift,” noted Lt. Col. George Schwartz, US government director for the F-35 ITF at Edwards. “The helmet mounted display test we are flying tonight is an example. The program asked us two days ago to fly an additional night flight for HMD testing. We are conducting that mission tonight.”

Edwards normally operates a daylight flying schedule, so a short-notice night mission requires a significant adjustment in schedules and resources across Edwards. “The night mission exemplifies the incredible support the F-35 ITF gets from the base,” Schwartz added.

The F-35 ITF at Edwards consists of more than 900 military, contractors, and civilian personnel from a variety of services, countries, and industries. In 2012, the ITF operated six F-35As assigned to Edwards—three for flight sciences testing and three for mission systems testing—as well as one F-35B temporarily deployed to Edwards from NAS Patuxent River, Maryland, for air start testing.

By the end of 2013, Edwards F-35 ITF will be operating three additional F-35s—two F-35Bs and one F-35C, for a total of nine F-35s. The test pilot population will expand from nine pilots to twelve pilots as well. The additional aircraft and pilots will be involved primarily with mission system testing.

Expanding The Envelope

Since receiving their first two F-35As (called AF-1 and AF-2) in May 2010, Edwards F-35 ITF personnel have been busy expanding the flight envelope.

“We spent the first two years turning the F-35 into a flying machine, but the focus has quietly shifted to weaponizing the aircraft in both flight sciences and mission systems,” Schwartz said. “Flight sciences work began with a small envelope. Today we’re flying at the edge of the envelope—at 100 percent loads—out to 1.6 Mach. Thanks to all the incredible work on envelope expansion done by this team, we are flying at seven g’s with no loads monitoring on our mission systems aircraft, and we have proven the aircraft can operate anywhere throughout the full envelope.”

The majority of the envelope expansion has been accomplished on AF-1, AF-2, and AF-4—the three F-35As devoted to flight sciences testing. F-35A AF-1 is flown in flutter tests. AF-2 is flown for most of the loads testing. And AF-4, recognizable by its spin recovery chute, is flown in high angle of attack test missions. These three aircraft alone accumulated about 600 hours of flying time in about 300 flights in 2012—approximately one-fourth of the total 1,167 System Design and Development missions for the entire fleet, which includes the test aircraft at Pax River.

Mike Glass, F-35 ITF site director at Edwards for Lockheed Martin, doesn’t see that level of activity diminishing for the flight sciences aircraft. “Envelope expansion testing remains significant in 2013,” Glass said. “We’ve completed the clean wing flutter flight sciences testing. Now we are installing pylons on the aircraft and doing the same type of flutter and loads testing we did with the clean wing. We will be conducting these tests for the next couple of years but with different load configurations on the aircraft.”

High angle of attack testing with the F-35 began in late October 2012. This testing involves taking the aircraft to its production angle of attack limit, which is fifty degrees. It also involves taking the aircraft beyond this limit to evaluate its characteristics in recovering from out-of-control conditions.

“High AOA testing produces some of the most challenging environments for the engine because the intake gets bad air,” explained David Nelson, lead F-35 test pilot for Lockheed Martin at Edwards. “The bad air creates a potential for producing a flameout, which is basically an engine shutdown. For that reason, air start testing preceded high AOA testing.”

Air start testing involves shutting down the engine and restarting it in flight. All four test pilots involved in high-AOA flight tests have flown air start missions. “The graduation exercise involved turning off the engine at 45,000 feet and then restarting it,” Nelson said. “Everything worked as planned.”

Besides producing conditions that can cause the engine to flame out, flying at high angles of attack can also lead to out-of-control flight. The spin recovery chute mounted at the apex of a four-legged structure on the back of AF-4 is designed to deal with that possibility. The test pilot can deploy this twenty-eight foot diameter parachute in case the airplane gets into an out-of-control condition from which the pilot cannot recover with the standard flight control inputs. The chute has not been needed to date.

“The airplane does quite well at high AOA,” Nelson added, “and the tests have been proceeding smoothly. We went from twenty degrees angle of attack to fifty degrees in only four days of testing.” Nelson and other pilots have also evaluated flying qualities at minus ten degrees AOA, which is the maximum design limit for negative AOA for the airplane. High AOA testing for 2013 will involve a variety of loadings mounted externally.

Loads Testing

Loads testing involves putting the aircraft in highly dynamic conditions to measure the stresses on the airframe and on other components. The tests verify the structural integrity of the F-35 in all flight regimes. Most of the loads testing has been flown on AF-2. US Air Force test pilot Lt. Col. Brent Reinhardt, who has been at the ITF since June 2012, has flown many of these missions.

“Loads missions can be physically demanding,” he said. “Some test points are hard to hit. I am diving at the ground at sixty degrees, doing Mach-one-point-whatever, and pulling 5.6 g’s while doing a roll—all this maneuvering just so we can hit a loads point at given speed and altitude conditions. Depending on the point, a lot of the runs start at Mach 1.3 and at altitudes nearing 50,000 feet. During the rolls, I increase the g’s so the flight test engineers on the ground can determine if we are overstressing any part of the airplane.”

Jennifer Schleifer is one of the flight test engineers who monitors and measures the loads on the aircraft during these test missions. Assigned to AF-2, she arrived at Edwards with the aircraft in May 2010. “We are flying on the edges of the structural envelope,” she explained, “and we have to make sure the airplane does not cross an edge. We spend a lot of time in the control room making sure that we won’t exceed structural limits.”

“We’re flying at Mach 1.6 and at more than seven g’s,” added Reinhardt. In a lot of the loads tests, pilots perform rolling maneuvers at a particular g. “Once we clear out a portion of the envelope at that g, we move to a higher g and repeat the testing process. We are shooting for a continuous g roll for 360 degrees through a certain block of altitude.”

In these maneuvers, the F-35 is often pushed to a very high roll rate, which is around 200 degrees per second.

“Operational pilots will never execute some of the maneuvers we’re performing in the airplane,” said Reinhardt. “But the maneuvers are part of building a flight envelope. We are verifying that the airframe will be fine structurally if it stays within the limits we are testing here.”

When not flying or conducting an actual mission, test pilots and flight test engineers practice the missions in a simulator. “We go to the simulator with a pilot to see if the more challenging loads points are achievable,” added Schleifer. “In the simulator, we can determine what Mach and what altitude the pilot needs to set up a particular run. We easily spend four hours in the simulator for every flight. We often return to the simulator to rehearse the points the morning of the flight. More practice in the simulator translates to greater mission efficiency in the air.”

Mission System Testing

“Flight sciences testing is fun,” Nelson said, “but it has its limits. Once an aircraft is good to nine g’s, it’s good to nine g’s. There’s no updating the flight envelope thereafter. Mission systems, on the other hand, will evolve for the life of the F-35, just as capabilities continue to evolve for the F-22 and F-16.”

Mission system testing deals with how the aircraft detects what is going on around it and how well it conveys that information to the pilot. Mission system tests are used to evaluate the functionality of the various electronic systems and sensors on the aircraft, including communications (datalinks and satellite communications), radar, countermeasures, distributed apertures, and electro-optical targeting.

Mission systems, combined with stealth, define the F-35. They separate fifth generation fighters from previous generation fighters.

“The F-35 was designed as a stealthy sensor platform,” added Reinhardt. “The aircraft can carry two 2,000-pound bombs and two AIM-120s internally. A similarly configured F-16 must carry those bombs and missiles externally, in the wind stream. Plus the F-16 has to add external fuel tanks as well as external targeting and countermeasure pods. These external loads reduce performance. And they increase radar cross section. We have to look at the whole picture when comparing fighters.”

Before mission systems are tested in the F-35s at Edwards, they are checked out on the ground in the mission systems integration laboratory in Fort Worth, Texas, and in the air in the Cooperative Avionics Test Bed (referred to as CATB, or CATbird), which is also based in Fort Worth.

The mission systems fleet at Edwards originally consisted of F-35A AF-3, AF-6, and AF-7. Unlike the flight sciences test aircraft, these three F-35s fly with a full complement of electronic systems and sensors found on operational F-35s. This current fleet will be increased with the three additional F-35s scheduled for delivery in 2013, which will also be used for mission system testing. F-35B BF-17 arrived in March. It was joined by BF-18 in April. CF-8 is expected to arrive later in the year.

“The additional aircraft coming in will help with multi-ship missions,” explained Glass. “As you can imagine, launching four aircraft for a mission at one time with only four aircraft available can be a real challenge even for an operational unit. Having six aircraft should improve our success.”

These multi-ship missions represent the increasing complexity and continuing evolution of mission system testing. Most of the mission system testing performed with the F-35 prior to 2013 involved single aircraft and even single sensors with limited sensor fusion, that is, the process for taking inputs from two or more sensors, combining them, distilling them, and then conveying them in an intuitive form to the pilot.

“At the system level, we are moving from testing individual systems or testing small federated groups of systems to testing fusion, where all of the sensors work together,” explained Capt. Nathan Yerrick, a US Air Force flight test engineer at the Edwards F-35 ITF.

“Eventually we will have all systems on,” Yerrick continued. “In terms of mission profiles, we had single F-35 operations early on. That is, one F-35 would go out with a chase aircraft. Now we are adding another F-35 as wingman, and the two F-35s are flying against multiple, maneuvering targets. In the next year or so, we will have our first four-ship F-35 mission with multiple maneuvering targets.”

Software

Because mission systems are common for the most part across all F-35 variants, the mission system testing done on an F-35A applies to the F-35B and F-35C. Similarly, the software that underlies the evolution is shared.

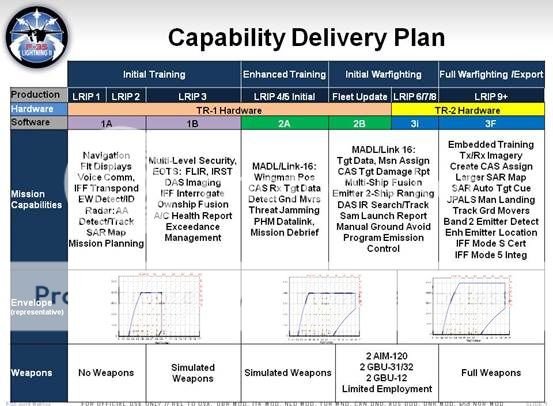

Capabilities associated with mission systems are being developed in a series of software blocks. Block 1 covers basic functions of the navigation system, the communication systems, and the sensors. With Block 1, the aircraft is limited to subsonic airspeeds, 40,000-foot altitude, 4.5 maximum g force, and eighteen degrees maximum angle of attack. Block 2A covers the Multifunction Advanced Data Link, the current Link-16, the maintenance data link, and a mission debriefing system.

Block 2B, which is the initial warfighting version of the software, adds capabilities associated with air-to-air and air-to-ground missions. It also has the complete set of maintenance functions. With Block 2B, the aircraft can be flown at supersonic speeds (up to Mach 1.2 for B- and C-models); at maximum g force of 5.5 and 7.5 for B- and C-models, respectively; and at maximum angle of attack of fifty degrees. The software also covers various loadings of the AIM-120 air-to-air missile, 2,000-pound JDAM GPS-guided bombs, and 500-pound GBU-12 laser-guided bombs.

Block 3, the full warfighting version of the software, is scheduled to be installed on production F-35s beginning with the ninth production lot, called Low-Rate Initial Production 9, or LRIP 9.

“We will wrap up the last of the mission system testing for Block 2A in summer 2013 and have already started testing 2B in the spring,” explained Eric Schutte, US government mission systems lead engineer at Edwards. “We corrected a lot of issues during our tests with 2A. The electro optical targeting system, for example, is working a lot better now. Link 16 is working well, too. We performed some interoperability tests with Link 16 last December. We will be doing a lot more interoperability testing with Block 2B.

“The software has come a long way,” Schutte added. “This is an incredibly complex airplane. Getting all the systems talking to each other can be a real challenge.”

Weapon Testing

Software updates are also delivering more weapon capability to the F-35. The test aircraft at Edwards began flying with weapons in 2012. The first bomb separation test occurred from F-35A AF-1 on 16 October 2012. The first AMRAAM separation test came three days later. The Edwards F-35 ITF is gearing up for about another twenty weapon drops in a series of weapon delivery accuracy tests for the spring and summer of 2013.

“We’ve done separation tests with the AMRAAM and a GBU-31,” said Bobby Rocha, a weapons integration engineer at the F-35 ITF. “These are the first steps toward actual weapon launch.”

Early weapon tests fall into the flight sciences regime. The initial separation tests are used to verify that the weapon separation characteristics conform to predictions. These initial tests are done on flight sciences aircraft—mostly on AF-1.

“We have a defined envelope for weapon releases,” Rocha noted. “We start with benign releases at higher altitudes, at one g, and at Mach 0.8. Then we come down in altitude and release at increased pressures. After that, we do releases at g forces above and below one g. Some of these test profiles are to establish an envelope so they are conducted at the edge of the operational envelope.”

As the envelope is established, the tests transition to the mission systems aircraft. “The weapon delivery accuracy tests are flown on the mission systems aircraft,” Rocha continued. “The delivery tests will be fairly simple at first. They will determine that the aircraft can hit a target with the weapon. That involves making sure the weapon receives the updates it needs from the aircraft, guides properly, and hits its target. The releases from mission systems aircraft will become more operationally representative and more complex as the testing proceeds.”

Maintenance Evaluations

Besides flight testing, the F-35s operating from Edwards are also being tasked to verify technical data used to maintain the aircraft and to evaluate and test the overall system for maintaining the F-35.

“For technical data, we have a list by US Air Force specialty codes for maintenance actions we want to evaluate,” explained Mary Parker, deputy for logistics at the F-35 ITF. “Whenever we have a maintenance task on the airplane that can be used to verify the technical data, representatives from the US government and Lockheed Martin are right behind the maintenance technicians asking if the techs have the information and the right tools they need. We are making sure that the maintenance task instructions can be performed in the field.”

The Edwards ITF has recently completed evaluations for servicing and towing the aircraft in chemical protection gear as well as for maintaining the engine. The chemical protection gear consists of overgarments, boots, and gas masks. “We are also evaluating weapons loading, which covers loading AMRAAMs and JDAMS into the internal weapon bays while wearing chem gear,” Parker continued. “In an upcoming phase, we will evaluate maintenance items related to low observable restoration. The maintenance personnel will be wearing chem. gear in these evaluations as well.”

Maintenance at the ITF is performed by personnel from Lockheed Martin as well as by civilians and military personnel working for the US Government. Four technicians come from international air forces—two from the Netherlands, one from Norway, and one from Canada.

“In many ways, the F-35 is easier to maintain than the F-16,” said Capt. Terje Vik, a maintenance lead from the Royal Norwegian Air Force. Vik has been at the F-35 ITF since the aircraft first arrived May 2010. “The F-35 has fewer LRUs [line replaceable units] and is more software driven. Normal scheduled maintenance is reduced. And the computer interface replaces a lot of test equipment. The aircraft also has more built-in test capability. Overall, fewer people are required to maintain the F-35.”

Delivering Capability

While the priorities on those flat screen panels positioned at the main entrance may change from day to day, the overarching goal for the F-35 ITF at Edwards remains constant: To deliver a highly capable fighter that is safe and meets all of its requirements.

“The testing we are doing now is focused on delivering capability,” concluded Schwartz. “Ultimately, we are delivering that capability to future generations of fighter pilots who will be operating the F-35.”

Eric Hehs is the editor of Code One.

- Joined

- 3 June 2006

- Messages

- 2,841

- Reaction score

- 2,530

LockheedMartinVideos - First F-35B Vertical Takeoff Test B)

Probably we will see more of these VTOs at airshows than in real service.

http://www.youtube.com/watch?v=zW28Mb1YvwYAn F-35B test aircraft completes the first-ever vertical takeoff (VTO) at NAS Patuxent River, Md., on May 10, 2013. While not a capability used in combat, VTOs are required for repositioning of the STOVL in environments where a jet could not perform a short takeoff. In these cases, the jet, with a limited amount of fuel, would execute a VTO to travel a short distance.

Code:

http://www.youtube.com/watch?v=zW28Mb1YvwYProbably we will see more of these VTOs at airshows than in real service.

- Joined

- 9 November 2008

- Messages

- 1,070

- Reaction score

- 137

USAF plans to go IOC in 2016 with Block 3I!!!

http://www.chicagotribune.com/business/sns-rt-us-lockheed-fighterbre94j0v0-20130520,0,6064960.story

We shall see. Official plans due by June 1st.

Here is a good breakdown of the blocks.

The above if from this Government Website:

https://zoek.officielebekendmakingen.nl/kst-26488-320.html

http://www.chicagotribune.com/business/sns-rt-us-lockheed-fighterbre94j0v0-20130520,0,6064960.story

Andrea Shalal-Esa

Reuters

8:33 p.m. CDT, May 20, 2013

WASHINGTON (Reuters) - The U.S. Air Force plans to start operational use of Lockheed Martin Corp.-built F-35 fighter jets in mid-2016, a year earlier than planned, using a similar software package as the Marine Corps {Block 3I} , two sources familiar with the plans said on Monday.

The Air Force's decision to accelerate its introduction with a slightly less capable version of the F-35 software package means the planes will carry fewer weapons at first, although the software will later be upgraded to the final version, said the sources, who were not authorized to speak publicly.

We shall see. Official plans due by June 1st.

Here is a good breakdown of the blocks.

The above if from this Government Website:

https://zoek.officielebekendmakingen.nl/kst-26488-320.html

topspeed3

ACCESS: Secret

- Joined

- 31 January 2011

- Messages

- 299

- Reaction score

- 81

Stargazer2006 said:flateric said:quite a rare pic I think

Thanks for sharing! Wish it was HD... Never realized the X-31 was that small compared to the X-32 and X-35!

Wasn't X-31 unarmed ?

- Joined

- 21 April 2009

- Messages

- 13,154

- Reaction score

- 6,018

- Joined

- 21 April 2009

- Messages

- 13,154

- Reaction score

- 6,018

F-35 ITF Works Toward Night, Weather Certification

(Source: U.S Air Force; issued May 23, 2013)

EDWARDS AIR FORCE BASE, Calif. --- The F-35 Integrated Test Force is wrapping up a series of night flights, which are testing the aircraft's capability when flying in instrument meteorological conditions.

It is a necessary step in delivering a core competency to the warfighter - the ability to fly the jet safely when there are no external visibility references for the pilot.

"This will increase the combat capability eventually. But, in the interim, it will increase the training capacity. The capability to fly at night and in the weather is one of the core competencies that must be delivered to the warfighter," said Lt. Col. Peter Vitt, F-35 ITF director of operations. "This is about safety, specification, compliance and predicting operational utility; it's our job to find out how well the system works, how well our pilots interact with the displays and how the navigational system works."

The ITF, which has the lead on all F-35 mission systems testing, is responsible for five night flights, with Naval Air Station Patuxent River, Md., conducting the sixth.

"The original intent was to spread the night flights around, three would be conducted here and three at Pax River with B and C variants," said Vitt. "But, as we moved into the execution phase, it made sense for us to do five here because of the variety in our pilots' backgrounds. Additionally, the airplanes fly essentially the same in an instrument environment and the mission system set is identical, so we leveraged that to make things more efficient."

For safety purposes and to ensure decision-quality data is collected, the ITF used a build-up approach to conduct the night flights. Pilots began with flying in visual meteorological conditions, familiarizing themselves with the F-35's leading-edge instrumentation.

Simulator flights, which occurred in February, also helped pilots prepare for the missions.

"This process has been in the works for many months; there is a build-up approach. We have been flying under good conditions during the day, using all the same displays. We also had to go through a series of simulator tests down in Ft. Worth, Texas where they can create those nighttime and weather conditions. Once we cleared that, we came back to fly at night," said Maj. Eric Schultz, F-35 test pilot.

"We're just finishing up those flights. The simulator is never going to be a perfect match so we had to fly it to see if the F-35 provides the displays, communications and other systems you need to safely fly at night or in weather when you're lacking the view of the outside world," he added.

When the ITF completes the night flights, a variety of capabilities will have been tested including ground operations and the pilot's ability to maneuver the aircraft without becoming disoriented. The test team will also evaluate the navigation systems, data from the instrument landing system, how well the radios work.

Just as important is the pilot's assessment, evaluating whether or not they are getting the necessary information and can adequately use it to make informed decisions.

From ground operations to landing and taxiing the aircraft, each mission is packed with test points, so the test team gets the most out of each flight.

"Ground operations, takeoff, how you get to the location you want to be at with no external references. Once you're where you need to be, the jet performs a series of different maneuvers to make sure the pilot can climb, turn and descend with relative precision without getting disoriented and not running into any problems," said Schultz. "Then it's time to go home, you complete an instrument approach process, descent, landing and then taxi the aircraft. We have test points for all of that."

Conducting instrument meteorological conditions testing proved to be somewhat of a challenge and required some ingenuity to make sure pilots had no external visual references, while avoiding weather conditions the aircraft is not yet cleared to fly in.

"There are certain weather conditions we haven't tested yet, so we can't fly there yet. We had to find a way to fly instrument conditions without flying in certain kinds of weather. The creative solutions the team came up with were to fly over the water and remote areas over land where there isn't cultural lighting to provide a horizon for the pilot," said Vitt.

"This is just another example of what happens here all the time, the ITF finds a way to accomplish the testing and get the data we need to overcome the various hurdles we see every day. It's just fantastic."

While still in the early development phase, the ITF has used the night flights as an opportunity to identify areas of improvement for the mission systems to better serve the warfighter. As the ITF successfully wraps up the night flights, the team's input will ultimately result in a safer, more capable weapon system.

This is not the first series of night flights for the F-35 ITF. In December 2011, a flight test only clearance was granted, so the test team could get an early look at the aircraft's refueling lights and assess night air refueling capabilities. Nighttime aerial refueling took place for the first time in early 2012, demonstrating the F-35's ability to safely and adequately perform the task.

-ends-

- Joined

- 6 November 2010

- Messages

- 4,225

- Reaction score

- 3,152

Eric Palmer has dug up the latest F-35 Selected Acquisition Report.

SAR attached.

SAR attached.

Executive Summary

The total F-35 program Research, Development, Test, and Evaluation (RDT&E) estimate decreased byapproximately $280 million (Base Year 2012). However, this SAR contains an RDT&E cost breach in the F-35 Engine subprogram. This breach is not the result of cost growth to the F-35 Engine subprogram. This administrative breach was driven by the correction of an error made in the allocation of program funding to the two subprograms. During the March 26, 2012 Acquisition Program Baseline (APB) build, the program office incorrectly allocated an additional 3.3 percent of the total RDT&E funding estimate to the F-35 Aircraft subprogram that should have been allocated to the F-35 Engine subprogram. This funding consisted of Other Government Costs, International contributions to engine development, and closeout costs for engine contracts. While this SAR corrects the allocation error for the RDT&E Current Estimate for both subprograms, it does not address the error in the March 26, 2012 APB. Therefore, the Department plans to revise the APB to correct the allocation error.

Additionally, the Department is reviewing the possibility of breaking out a third subprogram (F136 Engine) that would be added to the APB in order to accurately report the cost of the F135 Engine subprogram. The Department will provide the required congressional notification prior to taking this course of action. The next SAR submission will be based on the revised APB.

The F-35 remains the DoD's largest cooperative acquisition program, with eight International Partners (IPs) participating with the United States (U.S.) under Memorandums of Understanding for System Development and Demonstration (SDD) and Production, Sustainment and Follow-on Development. Additionally, the program has two Foreign Military Sales customers. The F-35 program has completed over eleven years of SDD and is currently executing Low-Rate Initial Production (LRIP).

The F-35 program continues to make slow, but steady progress and is moving forward in a disciplined manner. There were many successes as well as challenges in 2012. Successes include conducting the first in-flight weapons releases from both the Conventional Take-Off and Landing (CTOL) and Short Take-Off and Vertical Landing (STOVL) variants; stand up of the first operational STOVL squadron at Yuma Marine Corps Air Station (MCAS); executing edge of the flight envelope testing to the aircraft's maximum speed and altitude; and completing a U.S. Air Force operational evaluation clearing the way for the commencement of pilot and maintenance training at Eglin Air Force

Base (AFB).

In addition, challenges remain. During Calendar Year (CY) 2012, software block development, Autonomic Logistics Information System (ALIS), and the Generation II (Gen II) Helmet Mounted Display System (HMDS) remained the major focus of program execution. All three are key capabilities that directly impact the F-35 program's ability to reach Initial Operational Capability (IOC). Therefore, these areas will remain the focus in the coming year and through the completion of SDD.

Software risk remains the top development issue for the program. Over the past year, the F-35 program has implemented a major shift in the oversight and management of software development. This effort has resulted in increased cooperation and understanding between the program office and Lockheed Martin (LM). Additionally, the program instituted a Software Block Review Board that provides a forum for joint management of the Software Capability Block Plan (the integrated roadmap that defines the incorporation of capabilities). Although the positive results of these new efforts have built additional confidence in the Block 2B fleet release (required for IOC), the release of Block 3 to the fleet remains a higher risk for delivery in 2017.

The Gen II HMDS is a major technological advance and design challenge. HMDS issues faced by the program over the past year were:

(1) “green glow” or insufficient helmet display contrast,

(2) latency of the displayed information,

(3) “jitter” or lack of stability of the displayed symbology,

(4) night vision acuity and

(5) alignment of displayed symbology.

In CY 2012, significant work, including dedicated HMDS flight testing, was undertaken to address each issue and to better understand what constitutes acceptable HMDS performance. As a result of testing, the program has mitigated the effects of four of the five HDMS issues. Additional work still needs to be accomplished to ensure that the program has a night vision camera that is effective for operations. As risk reduction, the program continues to fund development of a night vision goggle-based alternative helmet solution. The goggle-based helmet development will continue until the HMDS demonstrates improvement in all of the risk areas.

ALIS provides the warfighter key information to support operations and maintenance. The program experienced a security issue with ALIS Version 1.0.3 (which is needed to operate and sustain aircraft in LRIP Lots 4 and beyond) in CY 2012. This issue was resolved in November 2012 and ALIS 1.0.3 is now fielded at Yuma MCAS), Edwards AFB, Nellis AFB, Ogden AFB, and Eglin AFB. There are some interim operational procedures necessary to mitigate security and data issues. Corrections for these interim procedures will be fielded in future ALIS releases.

During this SAR period, there were two issues that led to the grounding of the F-35 fleet. In both cases, after a system safety risk assessment was conducted and the issues were identified and understood, the fleet was cleared to resume flight operations.

The first issue was a failed propulsion fueldraulic line on the F-35B STOVL variant. The fueldraulic line enables actuator movement for the STOVL vectoring exhaust system. Evidence revealed a quality discrepency and the investigation found that the line was improperly crimped at the manufacturer. Corrective actions to improve the quality control processes to ensure part integrity have been instituted and all fleet test engines have been inspected.

The second issue was an engine blade crack in a test CTOL aircraft at Edwards AFB. The crack was found on a 3rd stage turbine blade during a routine inspection. The engine in question is part of the F-35 test aircraft fleet and had been operated for extended time in the high-temperature environment in its mission to expand the F-35 flight envelope. Prolonged exposure to high levels of heat and other operational stressors on this specific engine were determined to be the cause of the crack. No additonal cracks were found during inspections of the remaining F135 engine inventory. Investigation into the casting anomaly along with development of an inspection method continues and should be complete in mid-summer. The engine prognostic and health management system continuously measures life of turbine blades to keep the fleet safe and will determine if or when parts will need to be replaced based on condition many years from now. Current production continues by inspecting during the manufacturing process.

The SDD flight test program has accumulated over 4,333 total flight test hours through February 28, 2013. In CY 2012, the flight test program exceeded test points and flight targets for both F-35B and F-35C testing. The SDD flight test program also conducted the first in-flight weapons releases from the F-35A and F-35B. Additionally, the program began high angle of the attack testing which has been successful to-date.

Following the International Association of Machinists and Aerospace Workers strike at LM from April 23 to June 28, 2012, LM re-balanced the production line and adjusted scheduled deliveries to execute an achievable post-strike plan. Total assembly operations continue to progress according to the revised plan, improving from eight days behind the post-strike plan to only two days behind.

In CY 2012, the program delivered 30 total aircraft, 29 LRIP and the last SDD aircraft. All LRIP Lot 3 aircraft have completed acceptance flight test, and only one, AN-1, remains to be DD 250’d, pending funding from the Netherlands. Seven of 32 LRIP Lot 4 aircraft have been DD 250’d, with another twelve in flight and ground operations at LM, Fort Worth, Texas. The LRIP Lot 5 production contract for 32 aircraft was definitized in December 2012 showing a four percent decrease in unit cost from LRIP Lot 4. Nine LRIP Lot 5 aircraft have started the assembly process. 38 production aircraft have been delivered to the U.S. and IPs to-date.

The F135 propulsion contractor, Pratt and Whitney, delivered 24 CTOL and 24 STOVL propulsion systems in CY 2012. 87 engines and 35 lift fans (includes spares) have been delivered for the program to-date.

The Air Force Education and Training Command (AETC) conducted an Operational Utility Evaluation (OUE) in CY 2012. The OUE assessed the ability of the 33rd Fighter Wing to conduct pilot training. AETC determined the wing was ready for training and F-35 pilot training commenced in January 2013. Over the course of 2013, the training wing at Eglin AFB will prepare pilots for operational test, operational implementation and the stand-up of future training sites at Luke AFB and MCAS Beaufort in 2014.

The Integrated Training Center at Eglin AFB, Florida now has ten classes in session. These classes include the first Air Force certification courses on logistical support. Currently, there are students (both pilots and maint[en]aince personnel) from the Air Force, Navy, Marine Corps, and United Kingdom. Continued success of these training activities is very important as aircraft logistical support is a critical factor in the Services decision to declare IOC dates.

From a business perspective, the Government and LM reached agreement on LRIP Lot 5 in late November 2012 with full contract definitization on December 14, 2012. This effort also includes manufacturing-support equipment, flight test instrumentation, ancillary mission equipment and Diminishing Manufacturing Sources Redesign. The program is now moving forward with a streamlined, combined LRIP Lot 6 and LRIP Lot 7 negotiation. An LRIP Lot 6 Undefinitized Contact Action was awarded on December 28, 2012 and will be modified at a later date to procure three aircraft on behalf of the Italian Government and two aircraft on behalf of the Australian Government. Definitization of both LRIP Lot 6 and LRIP Lot 7 is anticipated by June 2013.

In March 2012, in conjunction with the MS B decision, certification was made pursuant to section 2366b of title 10, United States Code (U.S.C.). However, the Defense Acquisition Executive waived provision (3)(c) of 2366b. This provision certifies that the Joint Requirements Oversight Council (JROC) has completed its duties pursuant to section 181(b) of title 10, U.S.C., including an analysis of the operational requirements for the program. The JROC accomplished the bulk of its duties under section 181(b). However, because the IOC dates remained "to be determined" by the Services, paragraph (5) of section 181 (b) cannot be satisfied. The Services plan to publish their respective IOC dates in June 2013. At that time, this waiver will no longer be necessary.

Attachments

- Joined

- 6 November 2010

- Messages

- 4,225

- Reaction score

- 3,152

Defensetech: Congress orders F-35 Software Plan

More at the link.The House Armed Services Tactical Air and Land Forces Subcommittee asked the Pentagon to submit a report by March 3, 2014 as part of the committee’s markup of the 2014 defense budget. The F-35 software program has served as one of the largest challenges for program engineers to keep on schedule.

2IDSGT

Ah tale yew wut!

- Joined

- 27 November 2012

- Messages

- 365

- Reaction score

- 11

Amid Big F-35 Deal, P&W Sees Challenges

http://www.defensenews.com/article/20130526/DEFREG02/305260005/Amid-Big-F-35-Deal-P-W-Sees-Challenges

http://www.defensenews.com/article/20130526/DEFREG02/305260005/Amid-Big-F-35-Deal-P-W-Sees-Challenges

More at the jump.WASHINGTON — Pratt & Whitney has signed a $1 billion contract for the fifth batch of F-35 Joint Strike Fighter engines and expects to sign a sixth contract shortly, according to the company’s head of military engines.

The low-rate initial production (LRIP) contract with the US military includes 35 jet engines — 32 for installation and three spares — as well as sustainment, support and spare parts. The engines will power 22 of the F-35As for the US Air Force, three of the jump-jet F-35Bs for the Marine Corps and seven F-35C carrier variants for the Navy. Through the first four LRIPs, Pratt has delivered 98 engines to the F-35 program.

“We were able to close the LRIP-5 contract for about a 6 percent price reduction relative to LRIP-4, so we continue to get good cost reductions,” Bennett Croswell, president of Pratt’s military engines division, told Defense News last week.

As part of the contract, Pratt has taken on 100 percent risk on cost overruns, a move Croswell described as proof “we have confidence in our ability to hit the cost targets.” He also said that taking on risk may facilitate the signing of LRIP-6, which he hoped would be done “soon.”

During the interview, Croswell highlighted Pratt’s “War on Costs,” a 2009 plan to bring the price of the high-tech F-135 engine down to that of the older F-119 design, despite significant upgrades to thrust and weight...

- Joined

- 6 November 2010

- Messages

- 4,225

- Reaction score

- 3,152

Page 11 of Selected Acquisition Report:

Page 67:

Code:

Milestones SAR Baseline Dev Est

| Current APB Development

| Objective/

| | Threshold

| | | Current

| | | Estimate

Block 2B Fleet Release MAR 2015 [color=blue]MAR 2015[/color] SEP 2015 [color=blue]JUN 2015

[/color]Block 3F Fleet Release AUG 2017 AUG 2017 FEB 2018 AUG 2017

Completed IOT&E FEB 2019 FEB 2019 AUG 2019 FEB 2019

Full Rate Production Decision APR 2019 APR 2019 OCT 2019 APR 2019

DAB Milestone C APR 2019 APR 2019 OCT 2019 APR 2019Page 71:The Current Total LRIP Quantity is more than 10% of the total production quantity due to the necessity to prevent a break in production and to ramp up to full rate production. The Defense Acquisition Executive approved the Low Rate Initial Production (LRIP) quantity of 465 (in six LRIP lots) in the original Milestone B ADM dated October 26, 2001. The LRIP quantity has been revised to 365 (in eleven LRIP lots) based on the FY 2012 National Defense Authorization Act and the FY 2013 President's Budget.

The Services are currently reviewing their Initial Operational Capabilities (IOC) based on the restructured F-35 Program. The IOCs are determined by the Services based on both the program's performance and how the Services define IOC. Each Service has a somewhat different definition, depending on what capabilities they intend to have at IOC, their operational test (OT) and training requirements, and the number of aircraft they require for IOC.

The Services have requested, with the support of the Department, waiting to establish an IOC date. The Services require more definition in the program schedule regarding IOC requirements, to include OT dates, before targeting a timeline. The program anticipates the Services will identify their IOC dates in 2013.

aam641

One needs a personality to have a personal text!

- Joined

- 26 December 2011

- Messages

- 109

- Reaction score

- 11

AlJazeera video on US military expenditure. F-35 is mentioned a number of times from 5:00 mark onward, but there does not appear to be any new information.

- Joined

- 21 April 2009

- Messages

- 13,154

- Reaction score

- 6,018

F-35B Celebrates 1 Year At Eglin

(Source: U.S Air Force; issued May 28, 2013)

EGLIN AIR FORCE BASE, Fla. --- The Marine Fighter Attack Training Squadron-501 celebrated the one-year anniversary of flying the F-35B Lightning II here Wednesday, May 22, by continuing to train up the pilots and maintainers on the nation's newest fifth-generation fighter.

"This is a once in a lifetime chance to get to write the first chapter in a story that will last 50 years and beyond," said Lt. Col. David Berke, the commander of VMFAT-501 located at the 33rd Fighter Wing's F-35 Integrated Training Center.

The low-observable fighter is designed to meet the needs of the services for the next half a century, making use of integrated sensors, the active electronically scanned array radar, and the distributed aperture system. Combined they provide the pilot with increased situational awareness and survivability.

Being able to fly such a technologically advanced fighter brings great responsibility for cultivating tomorrow's defenders of freedom.

"We owe it to our country to get it right," said Berke. Under his charge, the unit is laying the foundation for pilot and maintenance training at Eglin and providing the fleet with highly-trained people as it moves forward toward providing the Marine Corps with an initial operating capability.

Since May 22 last year, the unit has flown 833 local training sorties and logged more than 1,100 flight hours executing about 40 to 50 sorties a week. "This is a bounding leap from the three or so sorties flown a week last year at this time," said Berke.

Other accomplishments include verifying joint technical data for weapons loading thus paving the way for instructions for all three services and the partner nations; authoring well over one-thousand maintenance procedures; and collaborating with industry and other F-35 sites to mature the jet, he said.

A senior leader with the F-35 program since flying the X-35 prototype aircraft in the early years and who is now the 33rd Fighter Wing's vice commander as well as an F-35B instructor pilot agreed.

"If you look at what they have accomplished in air-to-air refueling training, ground hot refueling, multi-aircraft missions, first fleet pilots trained.... you don't just see one-time events," said Marine Corps Col. Arthur Tomassetti. "What you see is a pattern of not just demonstrating new capability but turning it into repeatable and routine operations."

By being able to refuel with a truck planeside while the jet is running has allowed the unit to "increase its ability to turn sorties by 40 percent," he said. The hot refueling allowed eight F-35s to fly 16 sorties in three hours recently.

In addition to the unit accomplishments made locally, VMFAT-501 has been the catalyst to accomplishments at Marine Fighter Attack Squadron-121 at Marine Corps Air Station Yuma, Ariz.

VMFA-121 is the first operational fleet squadron anywhere in the world for the F-35 and comprised of flyers and maintainers trained at Eglin, according to Berke. Just last week a pilot trained here made his first vertical landing at Yuma. This feature allows the pilot to hover the fighter and set it down much like a helicopter.

"The ability to land in austere conditions is a key difference with the B variant of the F-35," said Berke. The Marines are planning to train the same way at Eglin in the fall.

For the upcoming year of flying, the Eglin unit also looks forward to receiving more jets to include its first Block 2A aircraft which means a software upgrade and increased capability, he said.

"We'll grow to 18 jets by this time next year," said Marine Corps Capt. Mario Valle, a maintenance officer at the training squadron. "And in the next couple weeks we are ready to welcome a third United Kingdom pilot and UK jet."

The Marines set another first this past year by hosting the first international pilots and maintainers imbedded at an F-35 training squadron. There are 14 maintainers and two pilots from the Royal Air Force and Royal Navy working seamlessly with the unit, said Valle.

As Valle reflected upon the past year he cited the team efforts by Lockheed Martin, Pratt and Whitney, Rolls Royce, the Marine Corps, Navy, the Air Force and operational test as key to past performance and the outlook for the future achievements.

"Our success has been based on relationships."

-ends-

- Joined

- 6 November 2010

- Messages

- 4,225

- Reaction score

- 3,152

From Aviation Week: U.S. Navy Details Amphibious Ship Mods Required For F-35

More at the link.[...]

Navy officials say the modifications “are intended to offset the increased stresses associated with JSF exhaust. The exhaust patterns and flight characteristics of the F-35 required the shielding, relocation and removal of vulnerable systems that could sustain damage during flight operations, such as antennas, life rafts, life rails, safety nets and JP-5 fuel stations.”

[...]

The changes confirm that Lockheed Martin and the Marine Corps issued erroneous statements in early 2010 regarding the environmental effects of the F-35B’s exhaust. At that time, a company spokesman said that “extensive tests” had shown that “the difference between F-35B main-engine exhaust temperature and that of the AV-8B is very small, and is not anticipated to require any significant CONOPS changes for F-35B.”

The Navy has not disclosed how long it will take to implement the modifications across the LHD/LHA fleet. The F-35 program schedule calls for the first Marine F-35B unit, VMFA-121, to be ready for a “contingency deployment” by late 2015. However, there is no firm date for a second squadron.

The mission for VFA-121 and other early F-35B units is uncertain. Out of the weapons cleared in the Block2B/3I software standard, only the laser-guided bomb is considered useful for close air support (CAS), which is the primary mission of embarked AV-8Bs, and none of the 2B weapons are suitable for use against quickly moving targets or for a situation in which the risk of collateral damage is high. (The centerline gun pod is not included in 2B/3I.)

The F-35B lacks the Rover (remote video receiver) technology, developed since the requirement for the aircraft was written. Rover has been defined as minimum essential equipment for CAS in some theaters; according to some military sources, the Marines have explored the idea of adding a Rover-equipped external targeting pod to the F-35B until an internal solution is available.

At the same time, the Navy has slowed its planned F-35B/C production rate by 20%, according to the latest Pentagon Selected Acquisition Report, resulting in a longer planned lifetime for the AV-8B. According to a Boeing briefing last week, “a majority” of the 134-strong Marine Corps Harrier force will be in service in 2027, and the type will not be retired before 2030. Radar and other upgrades are being studied to keep the aircraft combat-worthy and avoid obsolescence.

- Joined

- 6 November 2010

- Messages

- 4,225

- Reaction score

- 3,152

From Flight Global, 29 May 2013: USAF estimates F-35 will cost $32,000 per hour to operate

Compare, from Defensenews, 18 April 2013: F-35 Head: Flying Hours 10 Percent Higher than F-16

The US Air Force estimates that the Lockheed Martin F-35A Joint Strike Fighter will cost about $32,000 per flying hour to operate, the service's top uniformed official says.

"I think we've normalised to a couple of numbers now, about $25,000 per flying hour for the [Lockheed] F-16 C/D model and about $32,000 roughly for the F-35," says USAF chief of staff Gen Mark Welsh. "That number may continue to adjust itself slightly as we decide what factors are in or not, but that gives us an idea now."

The cost numbers have come down from original estimates, Welsh says, and as the USAF gains more experience in operating the F-35 it will glean a better understanding of the type's long-term operating costs.

Welsh cautions, however, that the aircraft is not yet flying operationally-representative sorties. "We're not flying in a fully operational mode yet, it's still in test," he says. "We're just starting our training programmes, so that data has to mature. Just like every airplane programme that has a projected cost for support and sustainment, we don't really know until we support and sustain it for a while."

There remains some maintenance equipment that needs to complete development, such the F-35's autonomic logistics information system.

"Some of the equipment that will help with that process is still being developed, and once we get more fidelity on that over the next couple of years I think we'll have a much better feel for what the airplane's going to cost," Welsh says.

Compare, from Defensenews, 18 April 2013: F-35 Head: Flying Hours 10 Percent Higher than F-16

WASHINGTON — Flying hours for the conventional-take-off-and-landing F-35A model will likely cost 10 percent more than that of an F-16, according to a government estimate.

U.S. Air Force Lt. Gen. Christopher Bogdan, the head of the F-35 joint program office, revealed the figures during testimony in front of the Royal Dutch Parliament defense subcommittee April 18.

"In his statement, Bogdan indicated that the cost per flying hour of an F-35A (variant employed by the U.S. Air Force and Royal Netherlands Air Force) is estimated to be $24,000 per hour; roughly 10 percent higher than F-16 cost per flying hour,” a joint program office spokeswoman wrote in a statement. “This data was derived in cooperation with the U.S. Air Force and the Department of Defense Cost Assessment & Program Evaluation Office (CAPE).”

[...]

topspeed3

ACCESS: Secret

- Joined

- 31 January 2011

- Messages

- 299

- Reaction score

- 81

It is relative to fuel burn too....191 kN of the F-35 ( non ab with SFC of 0.889 )...compared to 106-129 kN of the F-16.

http://fi.wikipedia.org/wiki/F-16_Fighting_Falcon

http://fi.wikipedia.org/wiki/F-16_Fighting_Falcon

- Joined

- 6 November 2010

- Messages

- 4,225

- Reaction score

- 3,152

From Aviation Week: USAF Accepts Limited Capability With 2016 F-35 IOC

More at the link.The U.S. Air Force, by far the largest presumed user of the F-35 fighter, has agreed to declare initial operational capability with a much more limited software and weapons capability that initially planned, according to a report sent to Congress May 31.

The Air Force now plans to declare initial operational capability (IOC) with 12 F-35As (and trained pilots and maintainers) in December 2016, before the long-awaited 3F software package is fully tested. The service previously planned to wait for the 3F package because it allows for an expanded engagement envelope and more diverse weapons.

[...]

Meanwhile, the U.S. Marine Corps is planning to declare IOC with 10 F-35Bs, designed for short takeoff and vertical landing (Stovl), as well as trained pilots, maintainers and support equipment, in December 2015. This is a slight shift of the most recent plan to attempt an IOC in summer 2015. The Marines will be the first customer to declare IOC with the aircraft, and they were aggressive in their approach because their aging AV-8Bs are difficult and expensive to maintain.

[...]

The Navy, which has pursued a risk mitigation strategy of buying Boeing F/A-18 E/Fs and EA-18Gs while waiting for the F-35, is taking a more conservative approach toward welcoming the aircraft carrier-capable F-35C into service. The Navy plans to declare IOC in February 2019. The Navy leadership emphasizes in its statement about the IOC plans that it will need the F-35C to “find, fix and assess threats, and, if necessary, track, target and engage them with lethal results in all contested environments.” These capabilities will require, at the least, 3F software as well as training to a larger mission set for an IOC declaration.

[...]

seruriermarshal

ACCESS: Top Secret

- Joined

- 4 May 2008

- Messages

- 1,177

- Reaction score

- 534

More F-35's arrive at Eglin Air Force Base

Updated: Wednesday, June 5 2013, 04:45 PM CDT

EGLIN AIR FORCE BASE -- Two more F-35 A joint strike fighters landed at Eglin Air Force Base today.

With the new additions, the base now has 25 of the new jets.

Eglin is a primary training center for pilots and maintenance crews from U.S. and foreign military branches.

http://www.weartv.com/news/features/top-stories/stories/more-f35s-arrive-at-eglin-air-force-base-32536.shtml

Updated: Wednesday, June 5 2013, 04:45 PM CDT

EGLIN AIR FORCE BASE -- Two more F-35 A joint strike fighters landed at Eglin Air Force Base today.

With the new additions, the base now has 25 of the new jets.

Eglin is a primary training center for pilots and maintenance crews from U.S. and foreign military branches.

http://www.weartv.com/news/features/top-stories/stories/more-f35s-arrive-at-eglin-air-force-base-32536.shtml

- Joined

- 21 April 2009

- Messages

- 13,154

- Reaction score

- 6,018

http://defensetech.org/2013/06/06/air-force-jsf-will-redefine-age-old-doctrine-for-fighters/#more-20525

Interesting quote;

“An F-35 is the equivalent of an F-16 with three fuel tanks, sniper pod, two 2,000-pound JDAMS {Joint Direct Attack Munitions}, two AMRAAMs { Advanced Medium Range Air to Air Missile} and two AIM 9Xs…. in a stealth configuration,” Davis explained. “That is not a configuration an F-16 can fly.”

------------------------------------------------------------

Game changing.

Interesting quote;

“An F-35 is the equivalent of an F-16 with three fuel tanks, sniper pod, two 2,000-pound JDAMS {Joint Direct Attack Munitions}, two AMRAAMs { Advanced Medium Range Air to Air Missile} and two AIM 9Xs…. in a stealth configuration,” Davis explained. “That is not a configuration an F-16 can fly.”

------------------------------------------------------------

Game changing.

seruriermarshal

ACCESS: Top Secret

- Joined

- 4 May 2008

- Messages

- 1,177

- Reaction score

- 534

F-35A completes 1st in-flight missile launch 06 Jun 2013

"6/6/2013 - EDWARDS AIR FORCE BASE, Calif. (AFNS) -- An F-35A conventional takeoff and landing aircraft completed the first in-flight missile launch of an AIM-120 over the Point Mugu Sea Test Range, June 5.

It was the first launch where the F-35 and AIM-120 demonstrated a successful launch-to-eject communications sequence and fired the rocket motor after launch -- paving the way for targeted launches in support of the Block 2B fleet release capability later this year"

http://www.af.mil/news/story.asp?id=123351580

"6/6/2013 - EDWARDS AIR FORCE BASE, Calif. (AFNS) -- An F-35A conventional takeoff and landing aircraft completed the first in-flight missile launch of an AIM-120 over the Point Mugu Sea Test Range, June 5.

It was the first launch where the F-35 and AIM-120 demonstrated a successful launch-to-eject communications sequence and fired the rocket motor after launch -- paving the way for targeted launches in support of the Block 2B fleet release capability later this year"

http://www.af.mil/news/story.asp?id=123351580

Attachments

seruriermarshal

ACCESS: Top Secret

- Joined

- 4 May 2008

- Messages

- 1,177

- Reaction score

- 534

seruriermarshal

ACCESS: Top Secret

- Joined

- 4 May 2008

- Messages

- 1,177

- Reaction score

- 534

- Joined

- 6 November 2010

- Messages

- 4,225

- Reaction score

- 3,152

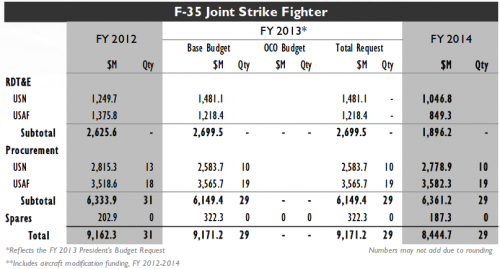

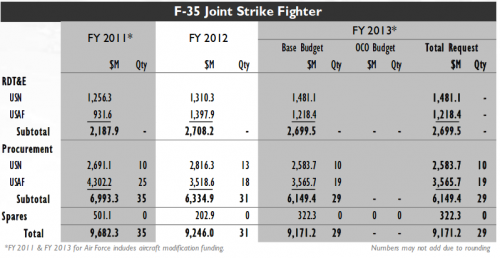

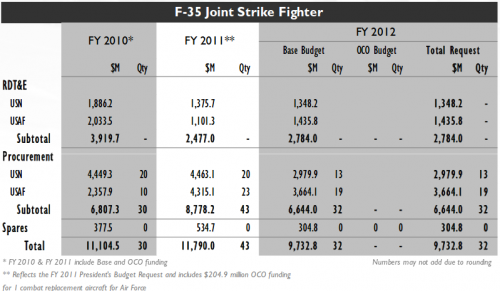

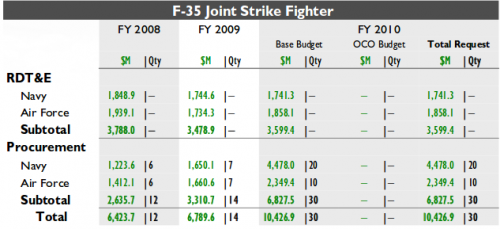

Winslow Wheeler argues F-35 procurement costs per aircraft have in fact gone up over the past three years:

His figures are based on Defense Comptroller data. I have extracted the relevant data from the 2010, 2012, 2013 and 2014 budget requests. The Comptroller's data are at odds with the latest SAR's view that costs are finally coming down.

From http://comptroller.defense.gov:

FISCAL YEAR 2010 BUDGET REQUEST

FISCAL YEAR 2012 BUDGET REQUEST

FISCAL YEAR 2013 BUDGET REQUEST

FISCAL YEAR 2014 BUDGET REQUEST

His figures are based on Defense Comptroller data. I have extracted the relevant data from the 2010, 2012, 2013 and 2014 budget requests. The Comptroller's data are at odds with the latest SAR's view that costs are finally coming down.

From http://comptroller.defense.gov:

FISCAL YEAR 2010 BUDGET REQUEST

FISCAL YEAR 2012 BUDGET REQUEST

FISCAL YEAR 2013 BUDGET REQUEST

FISCAL YEAR 2014 BUDGET REQUEST

Attachments

seruriermarshal

ACCESS: Top Secret

- Joined

- 4 May 2008

- Messages

- 1,177

- Reaction score

- 534

F-35C Heavy Weight Ground Tow Test 4 x 2,000 lb GBU-31s

"F-35C CF-3 was used for a heavyweight ground tow test at the Naval Air Warfare Center Aircraft Division test facility at NAS Patuxent River, Maryland, on 6 June 2013. The aircraft was fitted with four 2,000-pound GBU-31 guided bombs on the aircraft’s external pylons. US Navy Lt. Cmdr. Tony Wilson was in the cockpit during the test."

"F-35C CF-3 was used for a heavyweight ground tow test at the Naval Air Warfare Center Aircraft Division test facility at NAS Patuxent River, Maryland, on 6 June 2013. The aircraft was fitted with four 2,000-pound GBU-31 guided bombs on the aircraft’s external pylons. US Navy Lt. Cmdr. Tony Wilson was in the cockpit during the test."

Attachments

- Joined

- 6 November 2010

- Messages

- 4,225

- Reaction score

- 3,152

Defensenews reports: Japan might delay F-35 purchases.

More at the link.TOKYO — Former Japanese Defense Minister Satoshi Morimoto, the architect of Japan’s decision to purchase F-35 joint strike fighters to boost Japan’s deterrence against China, now believes cost pressures caused by the recent plummeting value of the yen could delay the rate of annual purchases for the country’s planned buy of 42 fighters.

In an interview with Defense News, Morimoto, who served as Japan’s defense minister until December and is one of Japan’s leading defense experts and strategists, said he now believes the Defense Ministry may be forced to delay annual purchases of F-35s, should the yen continue to hover around 100 to the US dollar.

“Because this was a decision by the government of Japan to introduce the F-35A, no matter what the price becomes, we cannot change our principle or our policy. We had to introduce the F-35 to replace the F-4. But the problem is … the price is increasing. The question then is how to manage it. I think the MoD has to reshape [the] number of purchases each year.

Fleet Grows, Training Increases for F-35

(Source: U.S Air Force; issued June 11, 2013)

EGLIN AIR FORCE BASE, Fla. --- The largest fleet of F-35 Lightning II joint strike fighters grew to 25 aircraft as the F-35 Integrated Training Center here welcomed two new Air Force F-35A variants of the multi-role fighter to the Emerald Coast, June 5.

The expansion gives the 58th Fighter Squadron the ability to fly an expanded schedule and more readily put student pilots through the F-35 training course, according to Maj. Jay Spohn, assistant director of operations at the 58th Fighter Squadron.

"We'll have the ability to fly a 'four-turn-four' or 'six-turn-four'," he said. The numbers indicate how many training sortie flights are accomplished in the morning schedule, then maintained and serviced to be turned back out to be flown for the afternoon schedule.

Currently, the Air Force team at the 33rd Fighter Wing is in the latter part of F-35A Pilot Class Number 4 and has started Class 5. The Marine Corps pilots here are in F-35B Class Number 4 and the Navy has completed one F-35C course and started a second this week. More than 30 pilots from all three variants have been trained at the F-35 Integrated Training Center.

The world class training devices, full mission simulators and comprehensive curriculum are preparing them for the challenges of working on the 21st century battlefield.

The Air Force expects to declare F-35A Lightning II initial operating capability by December 2016. For the Marines, the target date for F-35B IOC is in late 2015 and the Navy is looking at F-35C IOC in February 2019.

For now, the steps taken each day at Eglin assist in moving the F-35 program forward enterprise-wide as the team trains more people on the unprecedented, technologically-advanced 5th generation fighter.

About 72 pilots from the Air Force, Marine Corps and Navy are slated to graduate F-35 transition pilot training this year. This is made possible by a fleet of well-maintained aircraft to meet the training needs.

One such maintainer paving the way for F-35 success is Tech. Sgt. Lance Murphy, 58th Aircraft Maintenance Unit here. He received one of the two new F-35s and has been tapped to be the dedicated crew chief for that aircraft.

"This is awesome knowing the jet belongs to you," he said. "It's my responsibility to know the overall maintenance of this particular jet bearing my name on the side."

Murphy likened his F-35 maintenance experience to that of auto racing. "Each NASCAR has its own chief and each jet has its own crew chief. There is that same excitement when the jet is maintained and then goes out for a successful flight just like a successful race."

Spohn believe the steady stream of accomplishments for the F-35 are a direct result of the new training course, specifically designed for the new aircraft.

"It's an accomplishment that in less than six months since we started pilot training, we have been able to produce a course as good as any fighter course created in the last 20 years," said Spohn.

Murphy agreed about the progress. "Each day is something new and it's awesome to be a part of this."

At Eglin, the Air Force has 12 F-35A joint strike fighters, the Marine Corps has 11 F-35Bs and the United Kingdom embedded with the Marine Fighter Attack Training Squadron-501 has two F-35Bs. The Navy is slated to get its first two F-35C variants in the next coming weeks.

In the out years, when operating at full capacity, the Eglin fleet will grow to 59 aircraft with about 100 pilots and 2,100 maintainers graduating yearly.

-ends-

- Joined

- 21 April 2009

- Messages

- 13,154

- Reaction score

- 6,018

seruriermarshal

ACCESS: Top Secret

- Joined

- 4 May 2008

- Messages

- 1,177

- Reaction score

- 534

- Joined

- 21 April 2009

- Messages

- 13,154

- Reaction score

- 6,018

F-35 No Longer the Problem Child

The F-35 program has made “major advances” over the last three years and is no longer “one of my ‘problem programs,’” Pentagon acquisition, technology and logistics chief Frank Kendall said Thursday. Speaking during a teleconference following a multi-day summit with government, contractor and allied nation F-35 managers, Kendall said he’ll green light boosting the F-35 production rate in September; going to 44 in 2015 and 66 in 2016. The meeting had a “completely different tone” than last year’s summit, noted Kendell. The program is “on track,” he said. Negotiations on Lots 6 and 7 are going “more quickly and more smoothly” than on Lot 5, which were tough because it was the first based on DOD’s “should cost” analysis, he noted. Air Force Lt. Gen. Christopher Bogdan, program executive officer, reported far better communications between government and vendor managers, and agreed that Lot 6 and 7 talks are moving fast. “We started negotiations about a month ago, and we’ve made more progress…in 30 days than we did in about 11 months last year.” Kendall said “this is not the program of 2010,” and while he said it’s too soon to “declare success,” he said there’s a clear path to fix any remaining F-35 deficiencies. Operating costs are better understood now that the Marine Corps and Air Force are training F-35 pilots, and he predicted “we can make a substantial dent in projections” of operating costs. They will be reflected in the September cost numbers, he said.

The F-35 program has made “major advances” over the last three years and is no longer “one of my ‘problem programs,’” Pentagon acquisition, technology and logistics chief Frank Kendall said Thursday. Speaking during a teleconference following a multi-day summit with government, contractor and allied nation F-35 managers, Kendall said he’ll green light boosting the F-35 production rate in September; going to 44 in 2015 and 66 in 2016. The meeting had a “completely different tone” than last year’s summit, noted Kendell. The program is “on track,” he said. Negotiations on Lots 6 and 7 are going “more quickly and more smoothly” than on Lot 5, which were tough because it was the first based on DOD’s “should cost” analysis, he noted. Air Force Lt. Gen. Christopher Bogdan, program executive officer, reported far better communications between government and vendor managers, and agreed that Lot 6 and 7 talks are moving fast. “We started negotiations about a month ago, and we’ve made more progress…in 30 days than we did in about 11 months last year.” Kendall said “this is not the program of 2010,” and while he said it’s too soon to “declare success,” he said there’s a clear path to fix any remaining F-35 deficiencies. Operating costs are better understood now that the Marine Corps and Air Force are training F-35 pilots, and he predicted “we can make a substantial dent in projections” of operating costs. They will be reflected in the September cost numbers, he said.

Lockheed Martin, CAE Establish Canadian Training Alliance for the F-35 Lightning II

(Source: Lockheed Martin; issued June 17, 2013)

PARIS --- On the first day of the 2013 Paris Air Show, a new alliance between Lockheed Martin and CAE was announced when officials from both companies signed a Memorandum of Understanding (MOU) for F-35 Lightning II training system support and services in Canada. CAE is a global leader in modeling, simulation and training for civil aviation and defence.

“Canadian industry has played an integral part in the development and production of the F-35 for more than a decade,” said Steve O’Bryan, vice president of F-35 Program Integration and Business Development. “Canada’s industrial contribution to this program has truly just begun. The new alliance we established today is indicative of the long-term role Canadian industry will hold in the global sustainment of the F-35 fleet for the next 30 years and beyond, and directly supports the evolution of training systems, one of the key industrial capabilities recently promoted by the Government of Canada.”

During a ceremony held at the Canadian Pavilion at the Paris Air Show, O’Bryan and Gene Colabatistto, group president, Defence and Security at CAE, signed the MOU that identifies Quebec-based CAE as a preferred provider of in-country F-35 training support, training system integration, operations and maintenance.

“CAE and Lockheed Martin have a longstanding and successful relationship on other platforms such as the C-130, and we look forward to extending our collaboration should the Government of Canada select the F-35,” Colabatistto said. “Simulation-based training continues to grow in importance for defence forces as a cost-effective means of ensuring mission readiness, and CAE is focused on ensuring that the Royal Canadian Air Force has the world-class training services it needs to achieve targeted mission readiness levels.”

The 5th generation F-35 Lightning II combines advanced stealth with fighter speed and agility, fully fused sensor information, network-enabled operations and advanced sustainment. Three distinct variants of the F-35 will replace the A-10 and F-16 for the U.S. Air Force, the F/A-18 for the U.S. Navy, the F/A-18 and AV-8B Harrier for the U.S. Marine Corps, and a variety of fighters for other countries.

Headquartered in Bethesda, Md., Lockheed Martin is a global security and aerospace company that employs about 118,000 people worldwide and is principally engaged in the research, design, development, manufacture, integration, and sustainment of advanced technology systems, products, and services. The Corporation’s net sales for 2012 were $47.2 billion.

-ends-

Magellan Aerospace Signs Agreement For Work On F-35

(Source: Magellan Aerospace Corporation; issued June 17, 2013)

PARIS AIR SHOW, Le Bourget --- Magellan Aerospace has signed a Memorandum of Agreement (MOA) with BAE Systems for work on the F-35 Lightning II program.

Under the agreement Magellan will produce more than 1,000 sets of horizontal tails for the Conventional Take Off and Landing (CTOL) variant of the F-35 program over a 20-year period. The agreement, announced today at the Paris Air Show, Le Bourget, formalizes the continuation of the strategic relationship between BAE Systems and Magellan.

Magellan will produce F-35A horizontal tail assemblies using components that require advanced composite manufacturing, machining capabilities, and strict quality standards. The majority of the components used for the assembly are produced in Magellan's divisions. The horizontal tail production under the MOA has a potential value of over Cdn. $1.2 billion over the life of the program. Magellan has achieved sales of more than $100M Cdn. on the F-35 program to date.

Today's signing represents another milestone of Magellan's strategic involvement on the F-35 program. "We have supported Magellan's journey to become a key supplier of complex, flight critical components requiring high-technology, and high-quality manufacturing capabilities to produce the components to the exacting specifications demanded of this global program," said Paul Burns , Global Procurement & Supply Chain Director, BAE Systems.

Magellan is a part of the global F-35 team that includes world-class aerospace companies representing all eight JSF partner nations. Magellan's potential value of F-35 manufacturing work is approaching Cdn. $2.0 billion.

"At Magellan, we are proud to be an integral part of the F-35 supply chain. We've produced parts that are flying on all three variants, and for planes that will fly in four of the partnering nation's air forces," said Jim Butyniec, President and CEO of Magellan Aerospace. "We look forward to seeing the first Magellan-built horizontal tail assembly fly on a production F-35 in early 2014."

Magellan Aerospace is a global, integrated aerospace company that provides complex assemblies and systems solutions to aircraft and engine manufacturers, and defence and space agencies worldwide. Magellan designs, engineers, and manufactures aeroengine and aerostructure assemblies and components for aerospace markets, advanced products for military and space markets, industrial power generation, and specialty products.

-ends-

- Joined

- 6 November 2010

- Messages

- 4,225

- Reaction score

- 3,152

From breakingdefense: Marines launch drive to shove down F-35B costs

More at the link.[...]

One of the keys to bringing those F-35B costs down, [US Marines Lieutenant General] Schmidle said, may be doing intermediate level repairs at sea. “That will drive costs down and readiness up,” he told a small group of reporters here yesterday.

[...]

The Navy is also considering doing this with the Navy’s F-35C, although Lockheed Martin believes it may not be the most cost effective approach to managing aircraft repairs. The F-35, company officials say, was designed to be taken off the flight line when it comes time for repairs.

[...]

"Theft of F-35 design data is helping U.S. adversaries: Pentagon"

By David Alexander

Source:

http://news.yahoo.com/theft-f-35-design-data-helping-u-adversaries-184154837.html

By David Alexander

Source:

http://news.yahoo.com/theft-f-35-design-data-helping-u-adversaries-184154837.html

WASHINGTON (Reuters) - The theft of sensitive design data by hackers targeting programs like the F-35 Joint Strike Fighter takes away a big U.S. advantage by allowing rivals to speed up development of their own stealth aircraft, a top Pentagon official said on Wednesday.

Defense acquisitions chief Frank Kendall told a Senate hearing he was reasonably confident that classified information related to the development of the F-35 was well-protected.

"But I'm not at all confident that our unclassified information is as well-protected," he said.

"A lot of that is being stolen right now and it's a major problem for us," Kendall told a Senate hearing on development of the Lockheed Martin fighter, a so-called fifth generation aircraft capable of evading radar and integrated air defense systems.

The F-35 is the costliest weapons program in U.S. history. The United States is building it along with eight international partners and intends to purchase nearly 2,450 of the aircraft at a cost of almost $400 billion.

Responding to questions from senators concerned about whether cyber theft had left the F-35 vulnerable to attack, Kendall said his primary concern was that the design and production edge had been forfeited to competing powers.

"What it does is reduce the costs and lead time of our adversaries to doing their own designs, so it gives away a substantial advantage," Kendall said.

"It's the amount of time and effort they're going to have to put into getting their next design and staying with us," he added. "And as you're probably well aware, at least two nations are well into developing fifth-generation aircraft right now, so that's a concern."

Kendall did not name specific countries, but China and Russia are among the nations developing fifth-generation fighter jets.

The acquisitions chief said he was working on steps that would result in stronger sanctions against defense contractors who fail to do a better job at protecting their sensitive information systems.

CHINA REPORT

The remarks by the defense acquisitions chief came a month after the Pentagon said in its annual China report that Beijing was using cyber espionage to acquire advanced technologies to fuel its fast-paced military modernization program.

The report for the first time charged that cyber intrusions into U.S. government computer systems appeared to be directly attributable to the Chinese government and military, adding the main purpose was to benefit its defense industries.

Defense Secretary Chuck Hagel raised those concerns this month at the Shangri-La dialogue in Singapore, a multinational Asian security event that included a high-level Chinese military delegation.

U.S. President Barack Obama discussed the issue with Chinese President Xi Jinping at their summit in California a few days later, warning that if the intrusions were not addressed they would become a big problem in bilateral economic relations.