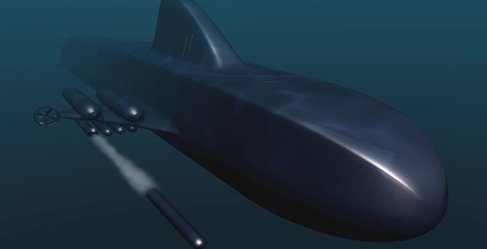

Direction des Constructions Navales Services (DCNS) unveiled a concept for a new submarine named SMX-24 at the Euronaval 2008 show in Paris held on October 27-31, 2008.

http://www.aviationweek.com/aw/blogs/defense/index.jsp?plckController=Blog&plckScript=blogScript&plckElementId=blogDest&plckBlogPage=BlogViewPost&plckPostId=Blog%3a27ec4a53-dcc8-42d0-bd3a-01329aef79a7Post%3a746c0b19-3d2c-4f1f-ab90-b68183d15701&plckCommentStealth aircraft have been compared to submarines, and there are similarities between the two. Both depend on a smooth outside mould line for survival and carry their weapons internally, restricted by the ability to cut holes in the skin.

But then DCNS unveiled its SMX-24 concept for an advanced submarine at the Euronaval show in Paris, and turned those presuppositions on their head.

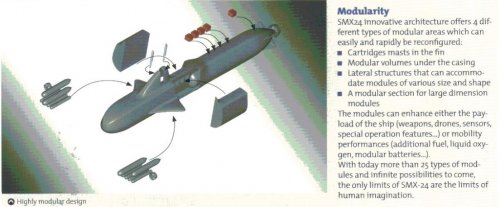

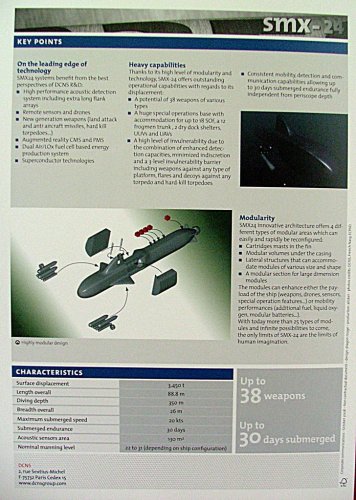

SMX-24 is a concept for a submarine that would be in service about 2020. Its size and capability fall between today's biggest diesel-electric boats and the smallest nukes: the 3450-ton boat would have an all fuel-cell propulsion system, would be capable of 20 kt submerged and could stay underwater for 30 days. The core vessel would have interchangeable modules for weapons or special forces equipment. The stub wings carry tip-mounted propulsors for high speeds - allowing the central pumpjet to be sized for cruise - and fighter-like pylons for fuel tanks - above the wings on the model - and weapons

http://www.digital-battlespace.com/2008/11/%E2%80%98plug-and-fight%E2%80%99-dcns-presents-next-generation-sub-at-udt-pacific/The all-new SMX 24 submarine will incorporate ‘plug-and-fight’ modules enabling it to be reconfigured on demand to changing mission needs. DCNS has already identified 25 modules suitable for ‘plug-and-fight’ according to Navy needs. These include the submarine’s weapons (mines, missiles, etc.), sensors and performance-enhancing add-ons (offering greater speed, manoeuvrability or endurance, as the case may be). The modules will be housed at the wings level, in the sail and under the bridge. Different combinations of modules result in high-performance SMX 24 configurations with capabilities tailored to specific missions.

All DCNS-designed warships combine highly modular design and production. The SMX 24 offers new prospects and a new level of modularity. This concept sub exercise has enabled DCNS to identify both architectural and technological solutions meeting the future needs of client navies.

Increased modularity means a lower cost of ownership because ‘plug-and-fight’ modules can be shared by multiple submarines and crews. Note also that the SMX 24 requires a crew of just 22.