I thought I saw a graph one time of an accelerometer which was a rather noisy signal around a mean almost zero which they had to average to find any evidence of net thrust.shockonlip said:Evidently the 2nd X-43A flight did some acceleration.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pulse Detonation Wave engines (PDE)

- Thread starter blackkite

- Start date

lantinian

ACCESS: Top Secret

- Joined

- 24 March 2007

- Messages

- 538

- Reaction score

- 165

'Yes, of course you do. I am just talking about keeping the Mach 4 conditions over Mach 6. That means speed of airflow and temperature. Current methods of slowing down incoming air actually put more energy into it. You get to a point where incoming air temperature does not allow you to achieve the needed compression ration ( hot air = low pressure air). Probably other complications arise too.You mean you don't use the inlet to slow the flow down to subsonic speeds before running it through the PDE?

There was a recent cutaway drawing of Hotol spacecraft project published in Flight International Online.

http://www.secretprojects.co.uk/forum/index.php?action=dlattach;topic=277.0;attach=43106

One interesting approach they used is to cool down incoming air and make the air-breathing system usable over a larger speed spectrum. Well, at least in theory.

shockonlip

ACCESS: Top Secret

- Joined

- 29 January 2008

- Messages

- 605

- Reaction score

- 48

Simon666 said:I thought I saw a graph one time of an accelerometer which was a rather noisy signal around a mean almost zero which they had to average to find any evidence of net thrust.shockonlip said:Evidently the 2nd X-43A flight did some acceleration.

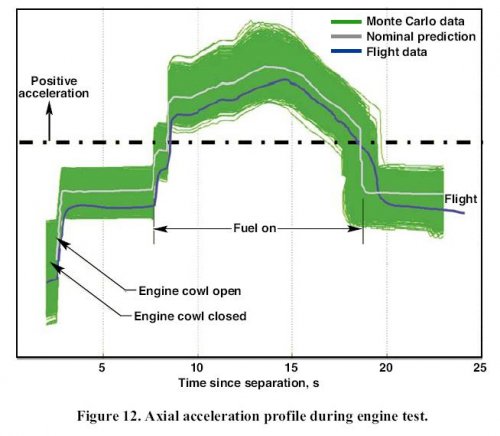

Attached is the X-43 chief engineer's Fig 12. pg.15 chart from their

AIAA paper: AIAA 2005-3332 on flight 2 (Mach 7).

The text associated with it is:

"During the time the engine was operating, the scramjet did accelerate

the vehicle and achieved performance very close to the preflight predictions.

Figure 12 shows the approximate flight axial acceleration curve as compared

to the nominal and Monte Carlo prediction data."

Attachments

shockonlip

ACCESS: Top Secret

- Joined

- 29 January 2008

- Messages

- 605

- Reaction score

- 48

quellish said:

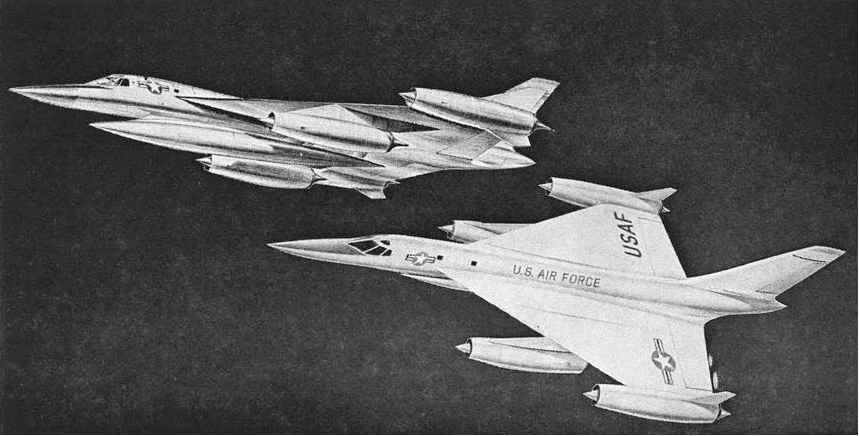

For a hypersonic aircraft the inlet is where it all comes together, which is why on designs like the X-30 it's so dominant, yet fully integrated with the rest of the aircraft, unlike subsonic or supersonic aircraft.

I wouldn't say that on a hypersonic vehicle the inlet is where it all comes together.

There are so many parts that have to be right for the type of mission (for example:

cruise or accelerator) that it is a large optimization problem that goes beyond just

the inlet.

airrocket

Dreams To Reality

Mach 12 is max for airbreather. Beyond M12 close the inlet and go all rocket. M20 is NASP type 0 to orbit air-breather BS. M6 is about max for LACE type OX collection. Sabre/Skylon propulsion design is a good example of using ram to rocket cycles skipping the nasty SCRAM cycle.

KJ_Lesnick

ACCESS: Top Secret

- Joined

- 13 February 2008

- Messages

- 1,042

- Reaction score

- 95

If it's not suited as a rocket engine, then wouldn't you want to work in air breathing mode more?

KJ

KJ

Matej

Multiuniversal creator

Nik

ACCESS: Top Secret

- Joined

- 15 July 2009

- Messages

- 1,236

- Reaction score

- 983

I'm concerned that PDE & Co. will go the tip-jet helo route. Neat notion, but thirsty, noisy and prone to exasperating misfire modes. Think SR71's notorious 'un-lights' in a rotary engine...

Still, there seems a potential envelope between ramjets, rockets and eg SABRE cycle...

==

Slightly OT: I'm reminded that some aspects of eg LACE and other hypersonic propulsion inlets are euphemistically labelled 'negative drag'...

Still, there seems a potential envelope between ramjets, rockets and eg SABRE cycle...

==

Slightly OT: I'm reminded that some aspects of eg LACE and other hypersonic propulsion inlets are euphemistically labelled 'negative drag'...

- Joined

- 31 December 2006

- Messages

- 799

- Reaction score

- 344

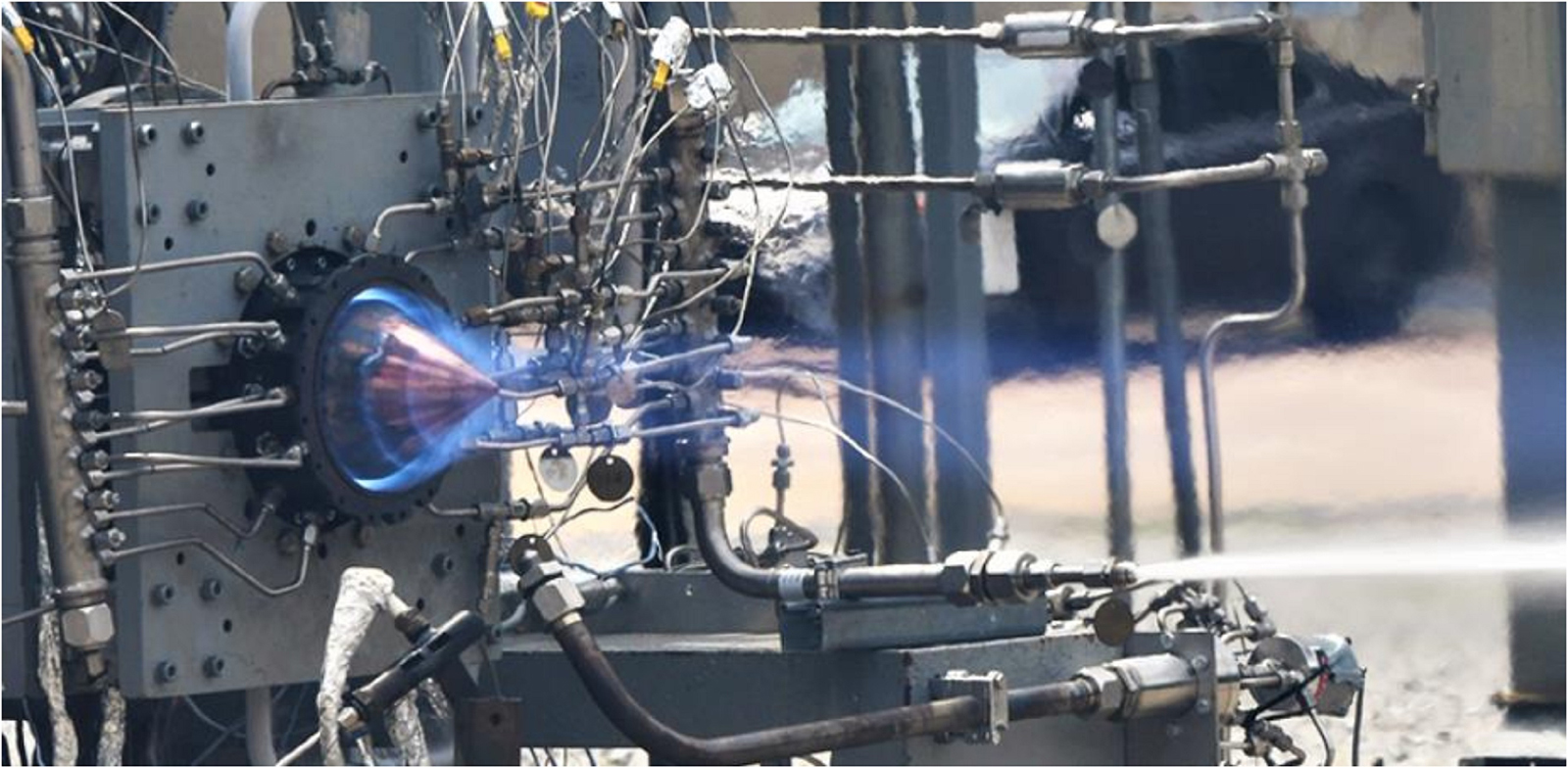

Aerojet Rocketdyne rotating detonation engine re-purposed for natural gas power plants:

http://www.rocket.com/article/aerojet-rocketdyne-mature-rotating-detonation-engine-technology-cooperation-department

http://www.rocket.com/article/aerojet-rocketdyne-mature-rotating-detonation-engine-technology-cooperation-department

marauder2048

"I should really just relax"

- Joined

- 19 November 2013

- Messages

- 3,157

- Reaction score

- 848

George Allegrezza said:Aerojet Rocketdyne rotating detonation engine re-purposed for natural gas power plants:

http://www.rocket.com/article/aerojet-rocketdyne-mature-rotating-detonation-engine-technology-cooperation-department

Intriguing given recent AFRL sponsored work into using LNG as an aviation fuel/heat sink/power source for next generation fighters.

https://www.researchgate.net/profile/Rory_Roberts/publication/280925005_Liquefied_Natural_Gas_as_the_Next_Aviation_Fuel/links/55cc8e7b08aebc967dfe2b69.pdf

marauder2048

"I should really just relax"

- Joined

- 19 November 2013

- Messages

- 3,157

- Reaction score

- 848

George Allegrezza said:A parallel RDE effort for DOD aerospace applications is mentioned in the AR release.

Thanks for pointing that out.

- Joined

- 21 January 2015

- Messages

- 11,318

- Reaction score

- 14,141

Aerojet Rocketdyne Explores Detonation Engine Options

http://m.aviationweek.com/technology/aerojet-rocketdyne-explores-detonation-engine-options

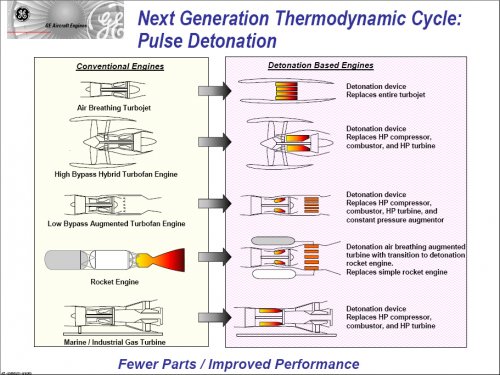

For over 70 years, jet engines have powered airplanes ever more safely and efficiently. But, despite higher core temperatures and pressures, and the introduction of efficient propulsion concepts like the geared fan, conventional gas turbines may be running out of runway. A fundamental change in the way a gas turbine combusts air and fuel in its core could open a path to a new era of jet engine development, however. Long pursued by propulsion researchers as a potential game-changing ...

http://m.aviationweek.com/technology/aerojet-rocketdyne-explores-detonation-engine-options

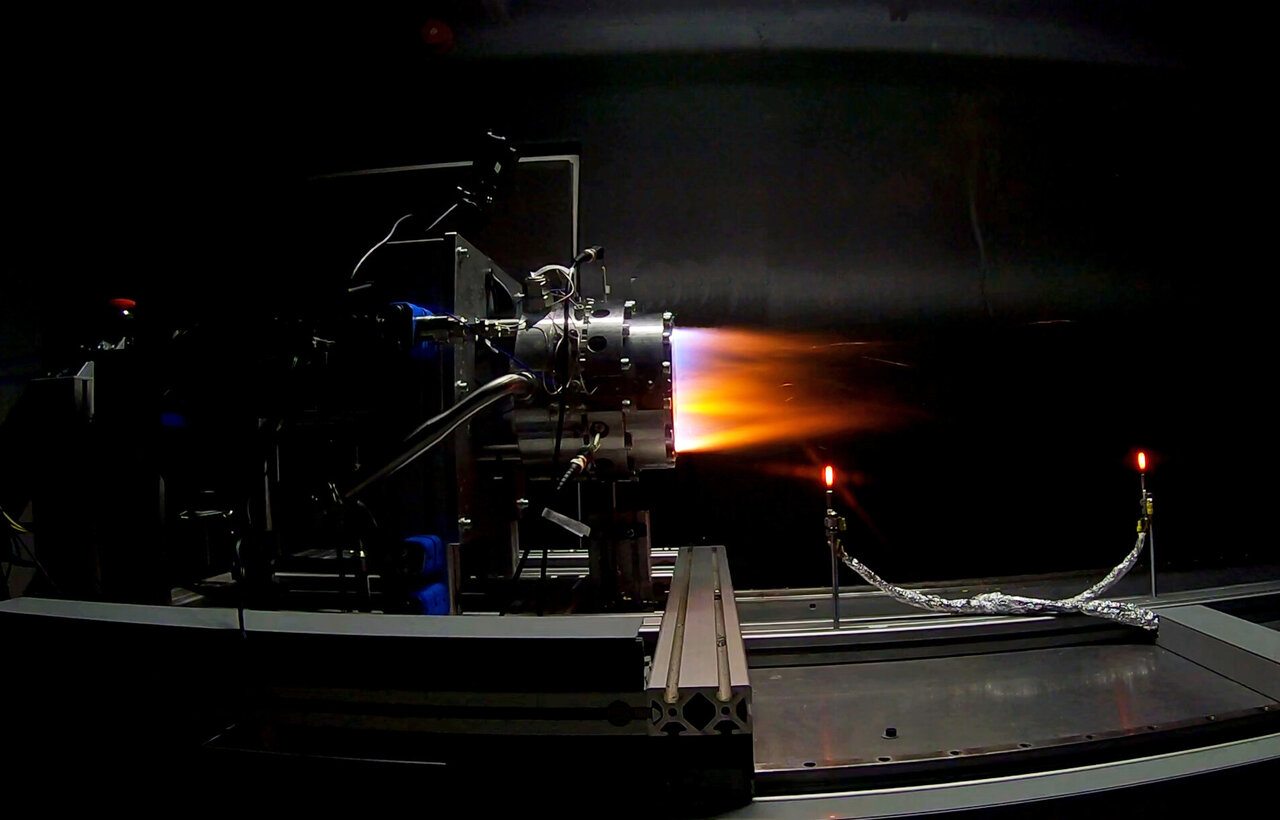

Australia and Germany successfully tested an RDE:

Pudsey said a major challenge to overcome was keeping the engine from overheating, while the next step of the project involved looking at a fully 3-D-printed, actively cooled version of the successful prototype.

Other challenges, including advanced modeling of the engine's behavior and integration of the engine into a functioning flight vehicle, remain to be overcome before proceeding to test flights.

Successful engine test brings Australian space launch capability a step closer

An Australian research consortium has successfully tested a next generation propulsion system that could enable high-speed flight and space launch services.

phys.org

- Joined

- 9 October 2009

- Messages

- 20,775

- Reaction score

- 11,722

View: https://www.youtube.com/watch?v=UwWIb3a4sSA

Tech Planet

171K subscribers

SUBSCRIBE

There are tons of weird and unconventional designs coming out. So let's look at some of the newest aerospace engines! Sources & Credits: 7. Jetopetra http://www.jetoptera.com/products/ 6. Electric Jet Engine https://spectrum.ieee.org/energywise/... https://asiatimes.com/2020/05/chinese... 5, Monarch 5 https://www.aerospacemanufacturingand... https://www.youtube.com/watch?v=anmcH... 4. Tempest Engine https://www.rolls-royce.com/products-... https://www.youtube.com/watch?v=xi8YV... 3. Fenris Air Rocket Engine https://arstechnica.com/science/2020/... https://www.facebook.com/MountainAero... 2. Pulse Detonation https://www.youtube.com/watch?v=1xVz1... (UC Detlab) https://www.youtube.com/watch?v=Joh3M... https://www.hindawi.com/journals/jc/2... https://www.ruaviation.com/news/2016/... 1. Rotating Detonation https://www.youtube.com/watch?v=i0yS-... https://www.youtube.com/watch?v=HRXVk... https://www.intechopen.com/online-fir... https://newatlas.com/space/rotating-d...

Nik

ACCESS: Top Secret

- Joined

- 15 July 2009

- Messages

- 1,236

- Reaction score

- 983

The RDE: Must wonder if there's some way to stabilise it by cross-linking, analogy with 'strapping' a cavity magnetron...

Perhaps 'resonance pots', per Acoustic jars ??

en.wikipedia.org

en.wikipedia.org

Perhaps 'resonance pots', per Acoustic jars ??

Acoustic jar - Wikipedia

shin_getter

ACCESS: Top Secret

- Joined

- 1 June 2019

- Messages

- 995

- Reaction score

- 1,297

Japan successfully tests rocket engine propelled by shock waves

The new technology could reduce engine sizes to about one-tenth the size of ones currently used on deep space spacecraft and would be able to operate for extended periods of time.

aonestudio

I really should change my personal text

- Joined

- 11 March 2018

- Messages

- 2,769

- Reaction score

- 6,730

Would this lend itself to autophage rockets-each grain deposited in such a way that each pulse eats a little more as part of a hybid system-the LOX and tech on a reusable upper stage. The inert all fuel lower stages being good shock absorbers?

aonestudio

I really should change my personal text

- Joined

- 11 March 2018

- Messages

- 2,769

- Reaction score

- 6,730

DARPA’S NEW MISSILE HINTS AT TRULY GAME-CHANGING TECHNOLOGY

Last week, the Defense Advanced Research Projects Agency (DARPA) quietly unveiled a new high-speed missile program called Gambit. The program is meant to leverage a novel method of propulsion that could have far-reaching implications not just in terms of weapons development, but for high-speed...

www.sandboxx.us

www.sandboxx.us

- Joined

- 21 January 2015

- Messages

- 11,318

- Reaction score

- 14,141

NASA's Advanced Rotating Detonation Variant Additive Rocket Chamber (ARDVARC-ACO) program is edging up to TRL 4

There is a short clip of it running in this video at about 1:47

aonestudio

I really should change my personal text

- Joined

- 11 March 2018

- Messages

- 2,769

- Reaction score

- 6,730

Rotating detonation engines at the forefront of pressure gain combustion

The Pressure Gain Combustion Technical Committee advances the investigation, development and application of pressure gain technologies for improving propulsion and power generation systems and achieving new mission capabilities.

Nik

ACCESS: Top Secret

- Joined

- 15 July 2009

- Messages

- 1,236

- Reaction score

- 983

I still think they need to 'cross-tie' RDE so becomes predictably cyclical...

IIRC, the Germans had toyed with magnetron concept but, unable to 'stabilise' the modes or frequency, discarded it. Apparently they were flabbergasted when they saw how a recovered RAF widget solved both problems: Modes by cross-linking, so did a sorta 'waltz' instead of just jitter-bugging, and frequency by designing associated transceiver with enough band-width to use what was generated instead of trying to constrain it...

IIRC, the Germans had toyed with magnetron concept but, unable to 'stabilise' the modes or frequency, discarded it. Apparently they were flabbergasted when they saw how a recovered RAF widget solved both problems: Modes by cross-linking, so did a sorta 'waltz' instead of just jitter-bugging, and frequency by designing associated transceiver with enough band-width to use what was generated instead of trying to constrain it...

aonestudio

I really should change my personal text

- Joined

- 11 March 2018

- Messages

- 2,769

- Reaction score

- 6,730

View: https://twitter.com/NASA_Marshall/status/1618315124447535128

NASA Validates Revolutionary Propulsion Design for Deep Space Missions

The high-performance propulsion system of the rotating detonation rocket engine has the potential to power both human landers and interplanetary vehicles to deep space destinations, such as the Moon and Mars.

- Joined

- 4 July 2010

- Messages

- 2,351

- Reaction score

- 2,548

SSME is very efficient for what it is, but there's so much more potential out there.

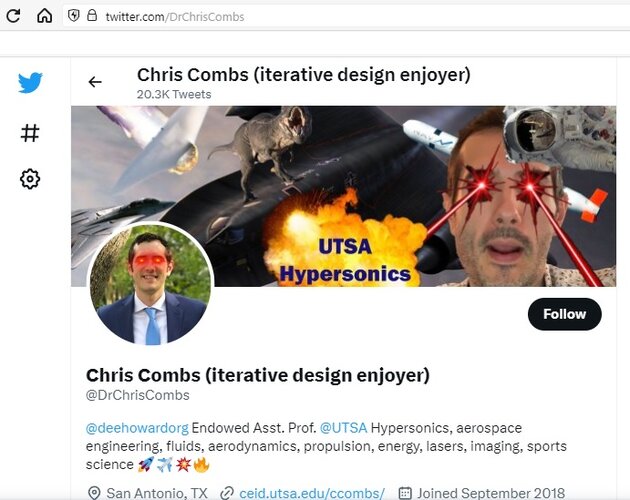

View: https://twitter.com/DrChrisCombs/status/1293172198484643840?t=3toRnjbfzy6tfxHiDfp2FQ&s=19

View: https://twitter.com/DrChrisCombs/status/1293172198484643840?t=3toRnjbfzy6tfxHiDfp2FQ&s=19

Dagger

ACCESS: Secret

- Joined

- 24 December 2019

- Messages

- 307

- Reaction score

- 538

I agree with sferrin.

I don't see which laws of thermodynamics or any other laws of physics can be circumnavigated by "rotating detonation" in a rocket engine.

That NASA RDRE rocket engine test at Marshall mentions 622 psi which is only 42 bar. They don't mention actual achieved ISP so that already says enough.

Chris Combs (who is that guy?) seems to be talking about air breathing engines, not rocket engines.

EDIT: in the mean time I found out that Chris Combs is an assisting professor at University of Texas San Antonio.

When I see somebody presenting himself with laser eyes I lose all respect:

I don't see which laws of thermodynamics or any other laws of physics can be circumnavigated by "rotating detonation" in a rocket engine.

That NASA RDRE rocket engine test at Marshall mentions 622 psi which is only 42 bar. They don't mention actual achieved ISP so that already says enough.

Chris Combs (who is that guy?) seems to be talking about air breathing engines, not rocket engines.

EDIT: in the mean time I found out that Chris Combs is an assisting professor at University of Texas San Antonio.

When I see somebody presenting himself with laser eyes I lose all respect:

Last edited:

- Joined

- 21 April 2009

- Messages

- 13,490

- Reaction score

- 6,949

NASA just test fired a rocket designed to power long-term Moon trips

NASA's new RDRE advanced rocket has just been successfully test fired at its Marshall Space Flight Center in Huntsville in Alabama.

- Joined

- 15 January 2021

- Messages

- 282

- Reaction score

- 930

In any heat machine, the efficiency is determined by delta temperature and delta pressure. The higher temperature and pressure that can be achieved in the working fluid when heat is added, the higher the efficiency. In air breathing engines, the pressure is limited by the capability of the fan and compressor. With a rotating detonation combustor, the supersonic detonation wave raises the pressure and temperature significantly higher than than the inlet pressure while shielding the compressor from that elevated pressure, greatly increasing the efficiency of the thermal cycle.

For a liquid fueled rocket engine, the fuel and oxidizer pumps have to deliver their liquids to the combustion chamber at higher pressures than the chamber pressure. Pressurizing liquid flow is much easier than than compressing air, but it is still a challenge. Rotating detonation combustion can once again raise the combustion pressure higher than the pump pressure, but it would not seem to be as much of an ISP advantage as for an air breathing engine.

For a liquid fueled rocket engine, the fuel and oxidizer pumps have to deliver their liquids to the combustion chamber at higher pressures than the chamber pressure. Pressurizing liquid flow is much easier than than compressing air, but it is still a challenge. Rotating detonation combustion can once again raise the combustion pressure higher than the pump pressure, but it would not seem to be as much of an ISP advantage as for an air breathing engine.

- Joined

- 3 June 2011

- Messages

- 17,794

- Reaction score

- 10,565

That's the explanation I was looking for.In any heat machine, the efficiency is determined by delta temperature and delta pressure. The higher temperature and pressure that can be achieved in the working fluid when heat is added, the higher the efficiency. In air breathing engines, the pressure is limited by the capability of the fan and compressor. With a rotating detonation combustor, the supersonic detonation wave raises the pressure and temperature significantly higher than than the inlet pressure while shielding the compressor from that elevated pressure, greatly increasing the efficiency of the thermal cycle.

For a liquid fueled rocket engine, the fuel and oxidizer pumps have to deliver their liquids to the combustion chamber at higher pressures than the chamber pressure. Pressurizing liquid flow is much easier than than compressing air, but it is still a challenge. Rotating detonation combustion can once again raise the combustion pressure higher than the pump pressure, but it would not seem to be as much of an ISP advantage as for an air breathing engine.

One question though. "significantly higher than than the inlet pressure while shielding the compressor from that elevated pressure" How does it do that? Shield the compressor that is?

Last edited:

- Joined

- 15 January 2021

- Messages

- 282

- Reaction score

- 930

With the Space Shuttle engines, they ran very high chamber pressures for high ISP. Their high pressure LH and LOX pumps were very troublesome over the years until NASA went to P&W for their expertise and replaced the original Rocketdyne pumps.

RDE may be a big advantage for smaller rocket engines that can't afford the weight and complication of high pressure turbopumps.

The other thing I noted was the use of a plug nozzle on the RDE rocket demonstrator. Plug nozzles have virtually unlimited variation in expansion ratios with no moving parts, while the conventional bell shaped convergent / divergent nozzle is either optimized for low altitude expansion into atmospheric pressure (i.e. a short divergent section), or into vacuum (a long divergent section). Some RL10 engines had an outer carbon fiber skirt that could be translated aft to make the divergent bell longer as the rocket extended. The plug nozzle, with the inner flow path defined by the plug, can readily adjust its supersonic expansion using the surrounding decreasing pressure ambient air to passively control the expansion ratio.

RDE may be a big advantage for smaller rocket engines that can't afford the weight and complication of high pressure turbopumps.

The other thing I noted was the use of a plug nozzle on the RDE rocket demonstrator. Plug nozzles have virtually unlimited variation in expansion ratios with no moving parts, while the conventional bell shaped convergent / divergent nozzle is either optimized for low altitude expansion into atmospheric pressure (i.e. a short divergent section), or into vacuum (a long divergent section). Some RL10 engines had an outer carbon fiber skirt that could be translated aft to make the divergent bell longer as the rocket extended. The plug nozzle, with the inner flow path defined by the plug, can readily adjust its supersonic expansion using the surrounding decreasing pressure ambient air to passively control the expansion ratio.

Ok so I downloaded one tech report about it (will attach it later).

That thing has potential to improve "classic" specific impulses by 10% average.

And thus, behold... (page 7 of the pdf, now attached)

-H202/ kerosene: 330 seconds plus 10% = 360 seconds

-Kerolox: 360 seconds - up to 400

-Methalox: from 375 to way above 400, 420 something.

-And hydrolox is even more startling: from the usual 460 to way, way above 500. Exactly what is needed to make SSTO happens with slightly less insane propellant mass fraction than 0.88 (with zero payload) or 0.90 and above (small payload).

And since that engine is high thrust, hence not an electric thruster with minuscule thrust...

That thing has potential to improve "classic" specific impulses by 10% average.

And thus, behold... (page 7 of the pdf, now attached)

-H202/ kerosene: 330 seconds plus 10% = 360 seconds

-Kerolox: 360 seconds - up to 400

-Methalox: from 375 to way above 400, 420 something.

-And hydrolox is even more startling: from the usual 460 to way, way above 500. Exactly what is needed to make SSTO happens with slightly less insane propellant mass fraction than 0.88 (with zero payload) or 0.90 and above (small payload).

And since that engine is high thrust, hence not an electric thruster with minuscule thrust...

Attachments

Last edited:

Would this tech best work for expendables? When I hear 'pulse' I remember the Titan II nozzle sawing incident. Hypergolics might be best for this-bleed a little of each in the other's tank....and hope the tanks empty 'afore something cracks? Titan II was near SSTO territory anyway-maybe this could push it over the line as it were. Martin Astrorocket more do-able now? A spaceplane with mass produced single use engines? Flip the script on Vulcan...keep the core-burn up the motor.

Last edited:

- Joined

- 3 June 2011

- Messages

- 17,794

- Reaction score

- 10,565

Plug nozzles have been around forever but the problem has always been keeping them cool. Non-afterburning turbojets tend to have them (the core section of high bypass engines, and older turbojets) but rockets have been rare.With the Space Shuttle engines, they ran very high chamber pressures for high ISP. Their high pressure LH and LOX pumps were very troublesome over the years until NASA went to P&W for their expertise and replaced the original Rocketdyne pumps.

RDE may be a big advantage for smaller rocket engines that can't afford the weight and complication of high pressure turbopumps.

The other thing I noted was the use of a plug nozzle on the RDE rocket demonstrator. Plug nozzles have virtually unlimited variation in expansion ratios with no moving parts, while the conventional bell shaped convergent / divergent nozzle is either optimized for low altitude expansion into atmospheric pressure (i.e. a short divergent section), or into vacuum (a long divergent section). Some RL10 engines had an outer carbon fiber skirt that could be translated aft to make the divergent bell longer as the rocket extended. The plug nozzle, with the inner flow path defined by the plug, can readily adjust its supersonic expansion using the surrounding decreasing pressure ambient air to passively control the expansion ratio.

- Joined

- 15 January 2021

- Messages

- 282

- Reaction score

- 930

The high bypass engine pictured has a center tailcone, but I think this is more of a flow director as part of the core flow / fan flow integration, since the exhaust flow is unlikely to be supersonic.

The Hound Dog missile with the J52 turbojet definitely had a plug nozzle since the nozzle pressure ratio was high enough for supersonic expansion and the flight envelope was fast enough to need the self adjusting nature of this design, But, as you noted, not afterburning.

The National Aerospace Plane SSTO designs showed a 2D plug nozzle in their Linear Aerospike concept.

The Hound Dog missile with the J52 turbojet definitely had a plug nozzle since the nozzle pressure ratio was high enough for supersonic expansion and the flight envelope was fast enough to need the self adjusting nature of this design, But, as you noted, not afterburning.

The National Aerospace Plane SSTO designs showed a 2D plug nozzle in their Linear Aerospike concept.

- Joined

- 15 January 2021

- Messages

- 282

- Reaction score

- 930

The detonation shock wave compresses the gas in front of it, so the gas being fed in by the pump (liquid) or compressor (air) behind the supersonic shock wave doesn’t feel that pressure increase.That's the explanation I was looking for.In any heat machine, the efficiency is determined by delta temperature and delta pressure. The higher temperature and pressure that can be achieved in the working fluid when heat is added, the higher the efficiency. In air breathing engines, the pressure is limited by the capability of the fan and compressor. With a rotating detonation combustor, the supersonic detonation wave raises the pressure and temperature significantly higher than than the inlet pressure while shielding the compressor from that elevated pressure, greatly increasing the efficiency of the thermal cycle.

For a liquid fueled rocket engine, the fuel and oxidizer pumps have to deliver their liquids to the combustion chamber at higher pressures than the chamber pressure. Pressurizing liquid flow is much easier than than compressing air, but it is still a challenge. Rotating detonation combustion can once again raise the combustion pressure higher than the pump pressure, but it would not seem to be as much of an ISP advantage as for an air breathing engine.

One question though. "significantly higher than than the inlet pressure while shielding the compressor from that elevated pressure" How does it do that? Shield the compressor that is?

Similar threads

-

-

-

-

-

Engineering Division GL- series (1920s aerial target gliders)

- Started by Jos Heyman

- Replies: 3