ford_tempo

ACCESS: Confidential

- Joined

- 31 January 2011

- Messages

- 78

- Reaction score

- 8

Hi

I found this paper:

more information is in the Wikipedia:

en.wikipedia.org

en.wikipedia.org

or here

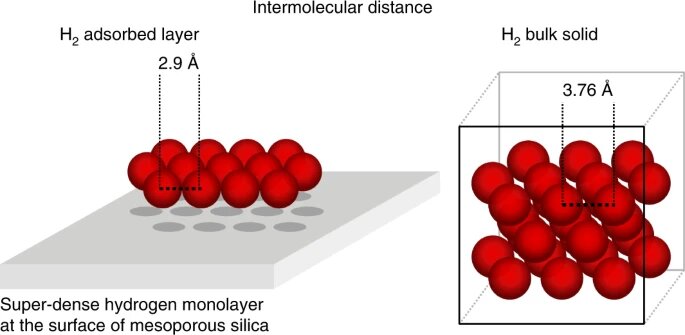

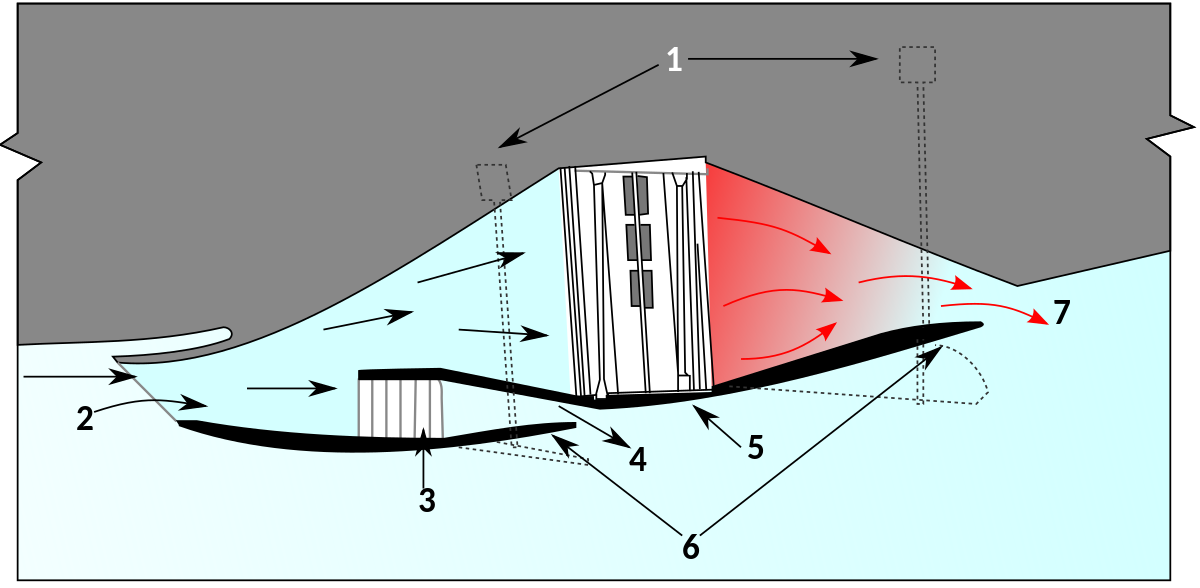

The idea is to use waste heat from the radiator in a piston engine to add heat to air compressed by ram effect in suitably shaped duct to increase engine efficiency.

I did't know it was applied to WWII engines of famous aircraft.

best

F_T

I found this paper:

more information is in the Wikipedia:

Meredith effect - Wikipedia

or here

The idea is to use waste heat from the radiator in a piston engine to add heat to air compressed by ram effect in suitably shaped duct to increase engine efficiency.

I did't know it was applied to WWII engines of famous aircraft.

best

F_T