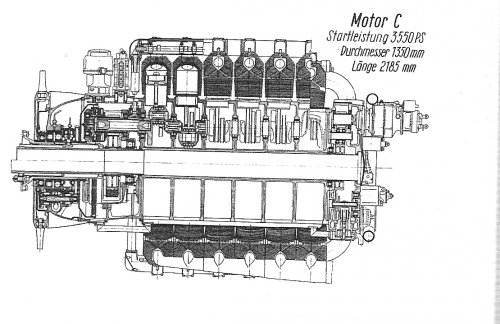

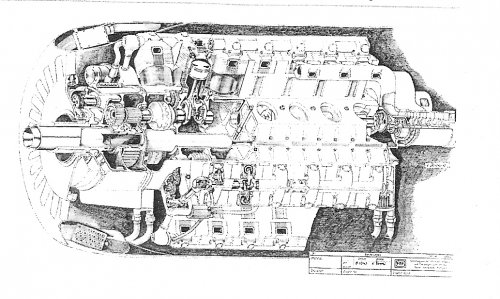

Professor Wunibald Kamm`s endeavours on aircraft engines date from the 1920`s, but the really interesting ones began with the "Bomber-B Programme", when he first designed, along with Wilhelm Krautter, a series of very interesting "gruppenmotoren" (32 and 48 cylinder). The "A" is well-known, but here I present you the "C" and "D", BOTH 48 cylinder engines.

Taken from "Wunibald I.E.Kamm - Wegbereiter der Modernen Kraftfahrtechnik", published by VDI-Verlag. The authors are Jürgen Potthoff and Ingobert C. Schmid. I strongly recommend this book to the ones interested in engineering. I would place Herr Kamm on a par with Ferdinand Porsche...

FKFS stands for Forschungsinstitut für Kraftfahrwesen und Fahrzeugmotoren Stuttgart

Taken from "Wunibald I.E.Kamm - Wegbereiter der Modernen Kraftfahrtechnik", published by VDI-Verlag. The authors are Jürgen Potthoff and Ingobert C. Schmid. I strongly recommend this book to the ones interested in engineering. I would place Herr Kamm on a par with Ferdinand Porsche...

FKFS stands for Forschungsinstitut für Kraftfahrwesen und Fahrzeugmotoren Stuttgart