Thread to discuss this family of lift engines, and aircrafts related. I've gathered some infos on the subject...

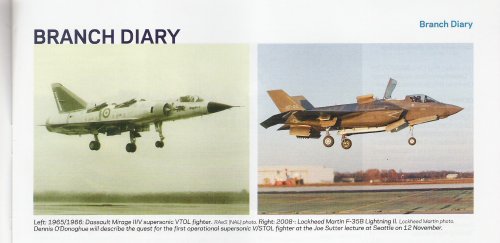

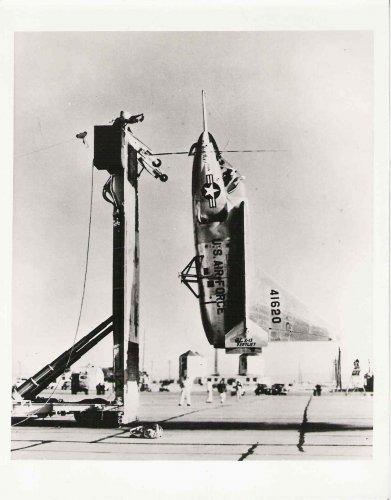

Le Fana de l'aviation, october 1997. Article on the Mirage IIIV.

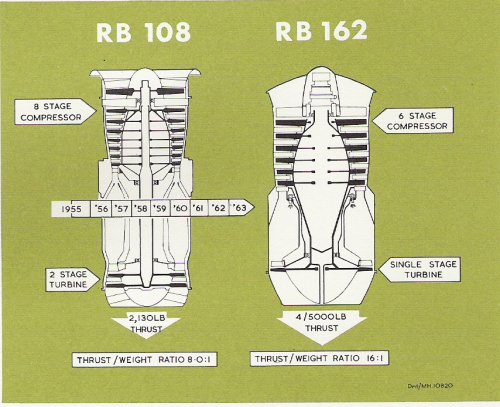

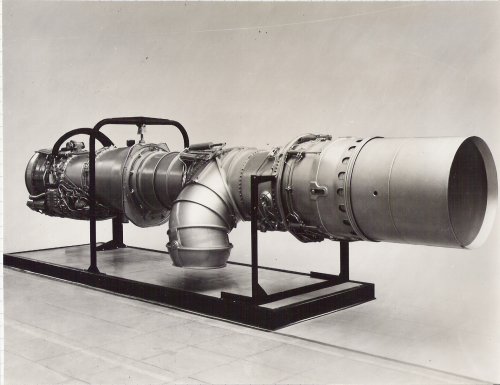

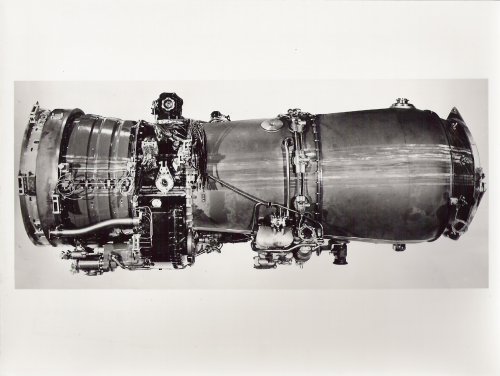

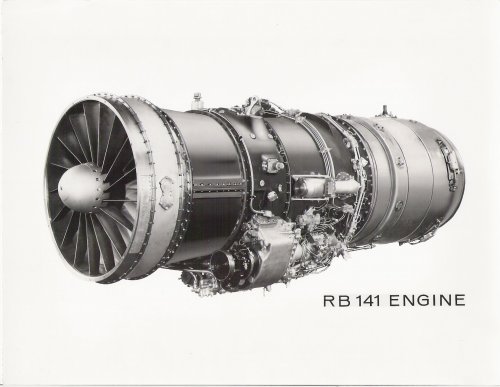

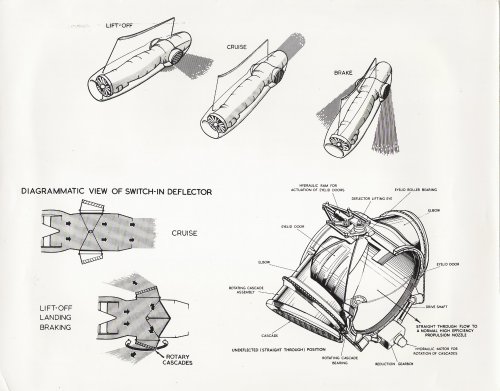

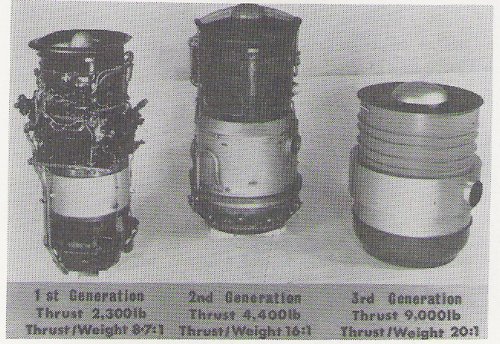

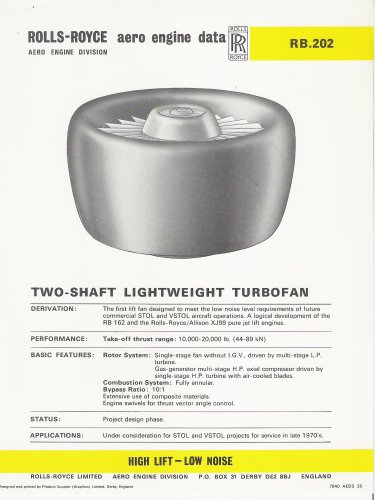

"Circa 1967 RB-162 were to be replaced by RB-189, product of a join program between RR and Allison. Thrust was 2700 kgp"

Skomer (superb website) Thust is given for 3500 kgp (for the AVS, circa 1968)

Le Fana de l'aviation, April 2003. Grumman 200 : 1* F-401 + two XJ-99 lift jets, thrust 4270 kgp.

Was the RB-189 / XJ-99 ever tested or did it remained a paper project ? more projects around this engine ?

Thanks in advance!

Le Fana de l'aviation, october 1997. Article on the Mirage IIIV.

"Circa 1967 RB-162 were to be replaced by RB-189, product of a join program between RR and Allison. Thrust was 2700 kgp"

Skomer (superb website) Thust is given for 3500 kgp (for the AVS, circa 1968)

Le Fana de l'aviation, April 2003. Grumman 200 : 1* F-401 + two XJ-99 lift jets, thrust 4270 kgp.

Was the RB-189 / XJ-99 ever tested or did it remained a paper project ? more projects around this engine ?

Thanks in advance!