- Joined

- 12 October 2009

- Messages

- 557

- Reaction score

- 213

To move on to the later developments at Derby we need to retrace our steps and understand the trials and tribulations of Power Jets and Rover. The technical side of the story- in detail for the WU and W1 and less so for W2 can be found in the First James Clayton lecture which can be downloaded here. Note you will have to pay if you go via Sage!

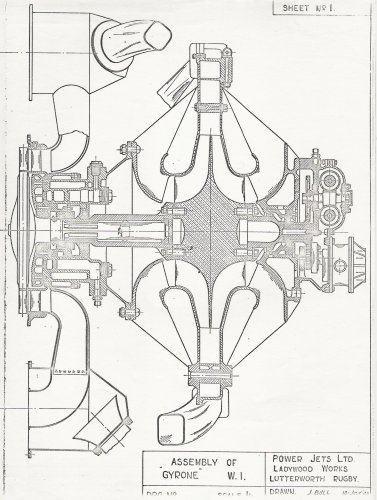

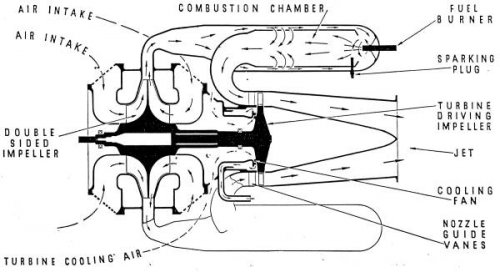

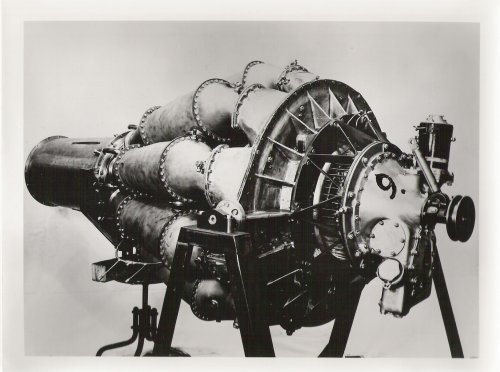

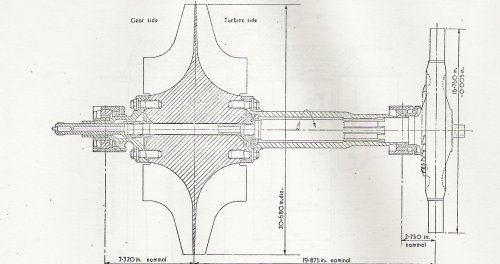

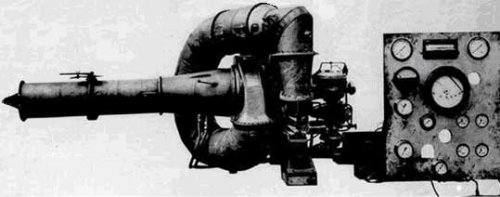

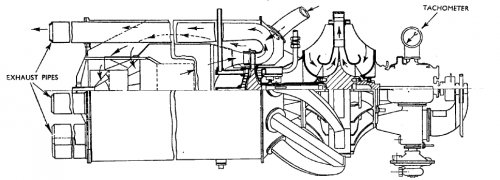

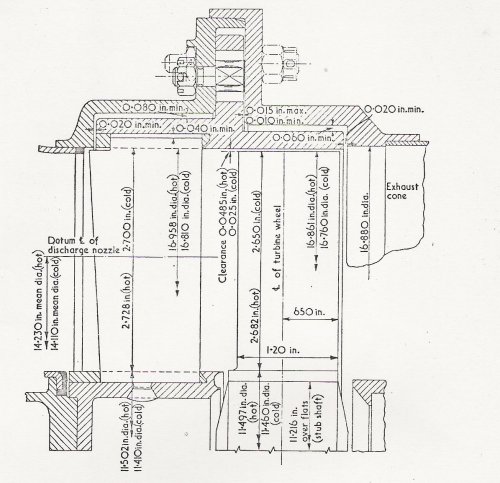

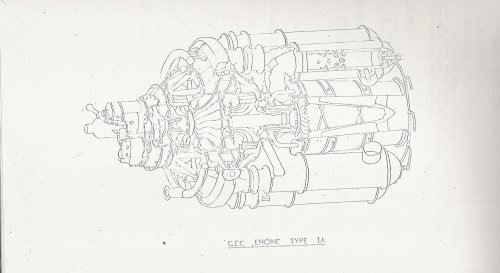

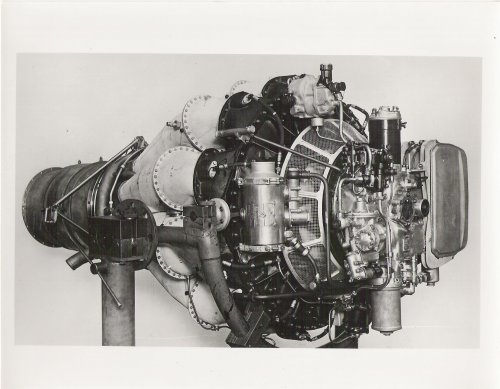

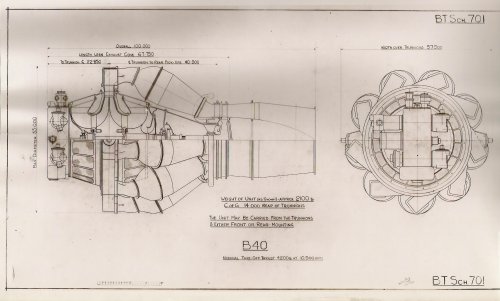

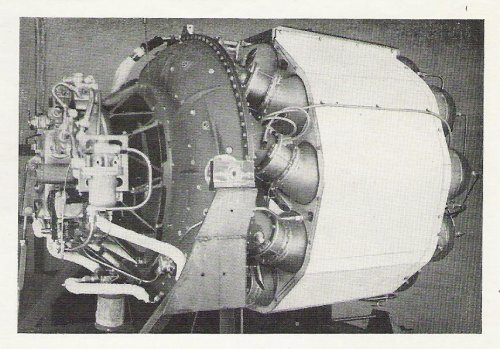

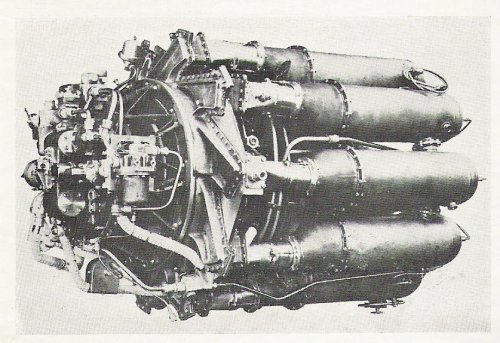

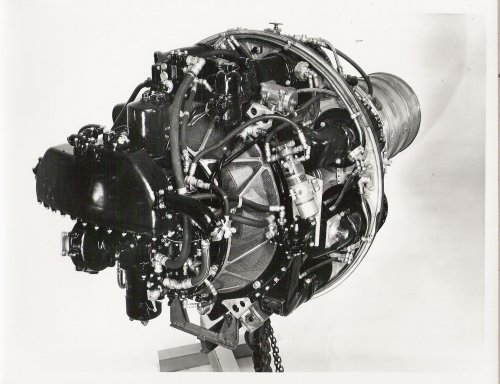

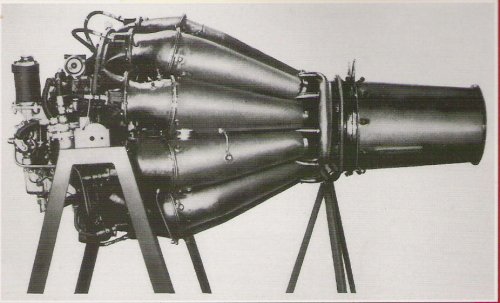

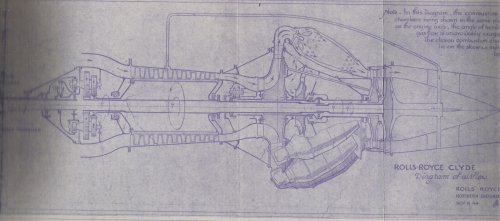

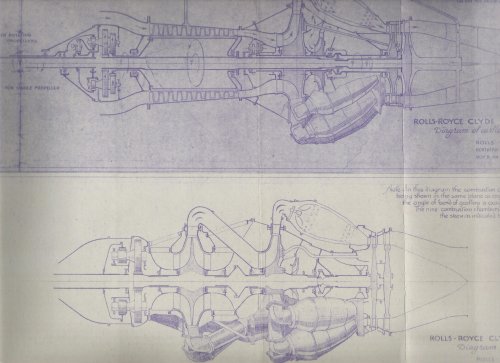

We will pick up the story as the W1 needs to be uprated. Jim Boal gave me a copy of his W1 drawing (below) and he will feature in the Tay story later.. he was unique in that he had continuity of working first at PJ, then Rover and transferring to RR. The W1 was basically a flightworthy redesign of the WU based on the same dimensions for rotating machinery.

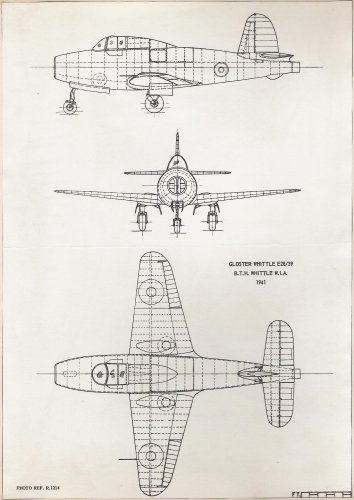

The idea for an aircraft (extract from On the aerodynamics of the Gloster E28/39 – a historical perspective by B. J. Brinkworth, the Aeronautical Journal June 2008:

"Gloster Aircraft Company had become part of the Hawker Siddeley Group in 1934. In 1939, the Company was producing the first of its Hawker Hurricanes, of which 2,750 were eventually built at the Gloucester plants. The Hurricane had been in service for barely two years, and so it will be appropriate to weigh features that emerged in the E28 against those already proven in the Hurricane, and, as the design proceeded, with Hawker’s successor, the Typhoon. This aircraft was also produced in quantity at Gloucester in due course.

The definitive version of the Whittle engine, around which the Specification was to be written, was the W2, intended to produce a

sea-level static thrust of 1,200lb. At a high cruising speed, this engine would give a thrust power comparable with that of the Rolls-Royce Merlin II installation of the Hurricane II, which was then going through the factory. However, the weight of the power-plant would be around a third of that of the Merlin and its associated equipment. Thus, a lighter and smaller aircraft could be envisaged, having correspondingly lower drag, with power available that would enable substantially higher performance to be obtained. The improvement would be greatest at higher altitudes, where the thrust of the jet engine was predicted to fall off less with height than that provided by a piston engine...............

........

Even in plan view, the fuselage still seems tubby, perhaps due to its size relative to the wings. The maximum width of the fuselage is around one-sixth of the span, twice the proportion for the Hurricane, for example.

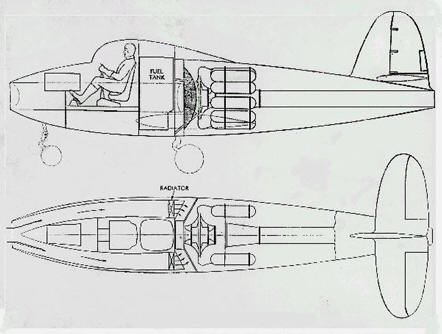

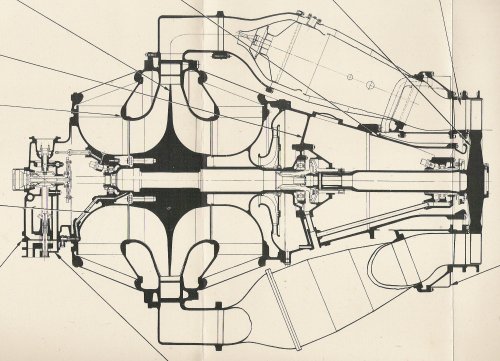

There was discussion on the effects of the flow required by the engine on the internal duct flow and external airflow. The nose intake and the ducting up to the engine bay were initially designed around the air mass flow-rate of 26lb/sec at sea level, then predicted for the W2 engine at maximum rpm. Whittle had assumed in performance calculations that the energy loss in the ducts would be 10% of the energy at inlet, a substantial penalty. Carter had accepted his advice that the mean velocity in the outlet of the duct, at the engine plenum chamber end, should not exceed 100ft/sec (though RAE representatives thought that the loss would not be 10% even if a mean velocity of 200ft/sec were used, as had been initially proposed by Gloster). At the nose, the diameter of the intake in the Intermediate design had been 18in, with an area of 1⋅76ft².

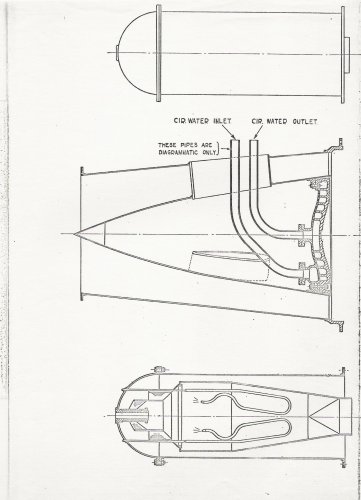

In the Final version, the diameter is 21in (area 2⋅4ft²), corresponding to a nominal mean inlet velocity of around 150ft/sec at the design point. This would have allowed also for the additional flow expected to be required to provide cooling air for the rear turbine bearing of the W1A and W2 engines, which would be used after the first few flights

Two ducts convey the air from the nose intake to the engine plenum chamber. Bifurcating the flow immediately after the intake, these are straight in elevation, passing along the sides of the fuselage, around the nose-wheel bay and the cockpit, to form two smooth curved tubes. Each has a non-circular and varying cross-section, with three full-length streamwise dividers. It would not have been a simple matter to calculate the flow losses in these, but no records of test measurements have been found. Significant further

losses would have been caused by the radiators, that were initially fitted at the engine bay ends of the ducts. These had been provided for cooling the W1 engine intended to be used for the taxying and initial flight trials, which, being based on the test-bed models, had a water-cooled turbine bearing. Fortunately, air-cooling became available for the W1A version, fitted after early trials with W4041, and for the W2 engines for the main series of tests with both aircraft, so the radiators were not then required.

The delivery of the intake air into a plenum chamber ahead of, and surrounding, the engine compressor casing meant that two bulkheads and part of the airframe structure were subjected to an internal pressure difference. It was agreed that this should be based on the full stagnation pressure at sea level maximum speed (410mph), about 3lb/in². Later, a design value of 5lb/in² was adopted, with a reserve factor of 2. This perhaps represents the first time that a substantial part of the primary structure of an aircraft had to support a pressure difference of this magnitude."

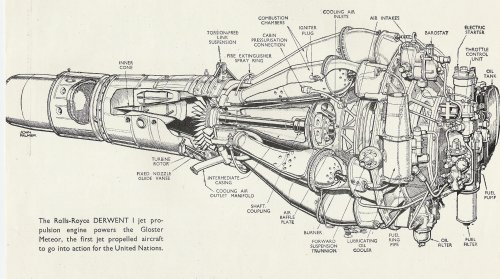

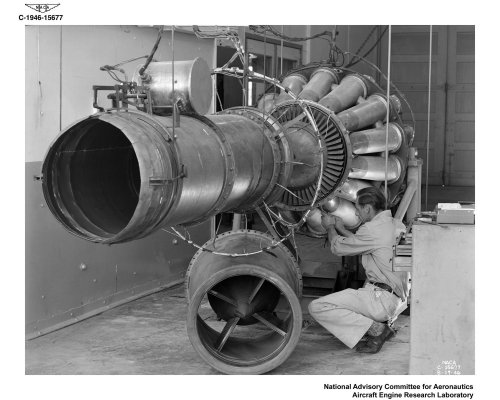

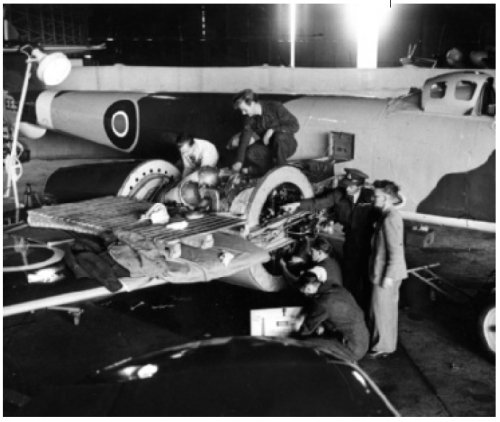

I have added drawings and photo of the aircraft to supplement the text.

We will pick up the story as the W1 needs to be uprated. Jim Boal gave me a copy of his W1 drawing (below) and he will feature in the Tay story later.. he was unique in that he had continuity of working first at PJ, then Rover and transferring to RR. The W1 was basically a flightworthy redesign of the WU based on the same dimensions for rotating machinery.

The idea for an aircraft (extract from On the aerodynamics of the Gloster E28/39 – a historical perspective by B. J. Brinkworth, the Aeronautical Journal June 2008:

"Gloster Aircraft Company had become part of the Hawker Siddeley Group in 1934. In 1939, the Company was producing the first of its Hawker Hurricanes, of which 2,750 were eventually built at the Gloucester plants. The Hurricane had been in service for barely two years, and so it will be appropriate to weigh features that emerged in the E28 against those already proven in the Hurricane, and, as the design proceeded, with Hawker’s successor, the Typhoon. This aircraft was also produced in quantity at Gloucester in due course.

The definitive version of the Whittle engine, around which the Specification was to be written, was the W2, intended to produce a

sea-level static thrust of 1,200lb. At a high cruising speed, this engine would give a thrust power comparable with that of the Rolls-Royce Merlin II installation of the Hurricane II, which was then going through the factory. However, the weight of the power-plant would be around a third of that of the Merlin and its associated equipment. Thus, a lighter and smaller aircraft could be envisaged, having correspondingly lower drag, with power available that would enable substantially higher performance to be obtained. The improvement would be greatest at higher altitudes, where the thrust of the jet engine was predicted to fall off less with height than that provided by a piston engine...............

........

Even in plan view, the fuselage still seems tubby, perhaps due to its size relative to the wings. The maximum width of the fuselage is around one-sixth of the span, twice the proportion for the Hurricane, for example.

There was discussion on the effects of the flow required by the engine on the internal duct flow and external airflow. The nose intake and the ducting up to the engine bay were initially designed around the air mass flow-rate of 26lb/sec at sea level, then predicted for the W2 engine at maximum rpm. Whittle had assumed in performance calculations that the energy loss in the ducts would be 10% of the energy at inlet, a substantial penalty. Carter had accepted his advice that the mean velocity in the outlet of the duct, at the engine plenum chamber end, should not exceed 100ft/sec (though RAE representatives thought that the loss would not be 10% even if a mean velocity of 200ft/sec were used, as had been initially proposed by Gloster). At the nose, the diameter of the intake in the Intermediate design had been 18in, with an area of 1⋅76ft².

In the Final version, the diameter is 21in (area 2⋅4ft²), corresponding to a nominal mean inlet velocity of around 150ft/sec at the design point. This would have allowed also for the additional flow expected to be required to provide cooling air for the rear turbine bearing of the W1A and W2 engines, which would be used after the first few flights

Two ducts convey the air from the nose intake to the engine plenum chamber. Bifurcating the flow immediately after the intake, these are straight in elevation, passing along the sides of the fuselage, around the nose-wheel bay and the cockpit, to form two smooth curved tubes. Each has a non-circular and varying cross-section, with three full-length streamwise dividers. It would not have been a simple matter to calculate the flow losses in these, but no records of test measurements have been found. Significant further

losses would have been caused by the radiators, that were initially fitted at the engine bay ends of the ducts. These had been provided for cooling the W1 engine intended to be used for the taxying and initial flight trials, which, being based on the test-bed models, had a water-cooled turbine bearing. Fortunately, air-cooling became available for the W1A version, fitted after early trials with W4041, and for the W2 engines for the main series of tests with both aircraft, so the radiators were not then required.

The delivery of the intake air into a plenum chamber ahead of, and surrounding, the engine compressor casing meant that two bulkheads and part of the airframe structure were subjected to an internal pressure difference. It was agreed that this should be based on the full stagnation pressure at sea level maximum speed (410mph), about 3lb/in². Later, a design value of 5lb/in² was adopted, with a reserve factor of 2. This perhaps represents the first time that a substantial part of the primary structure of an aircraft had to support a pressure difference of this magnitude."

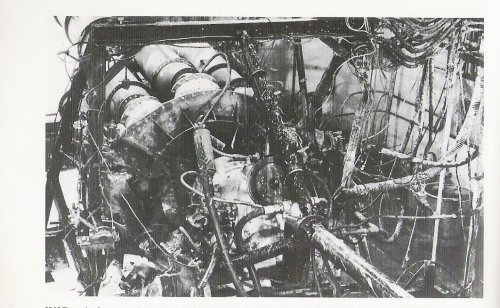

I have added drawings and photo of the aircraft to supplement the text.